Preparation method of surface plasmon metamaterial

A surface plasmon and metamaterial technology, which is applied in the fields of nanophotonics and nanofabrication, can solve the problems of low yield, high cost, and few types of processing structures, and achieves huge application potential, simple process method, and enhanced optical absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

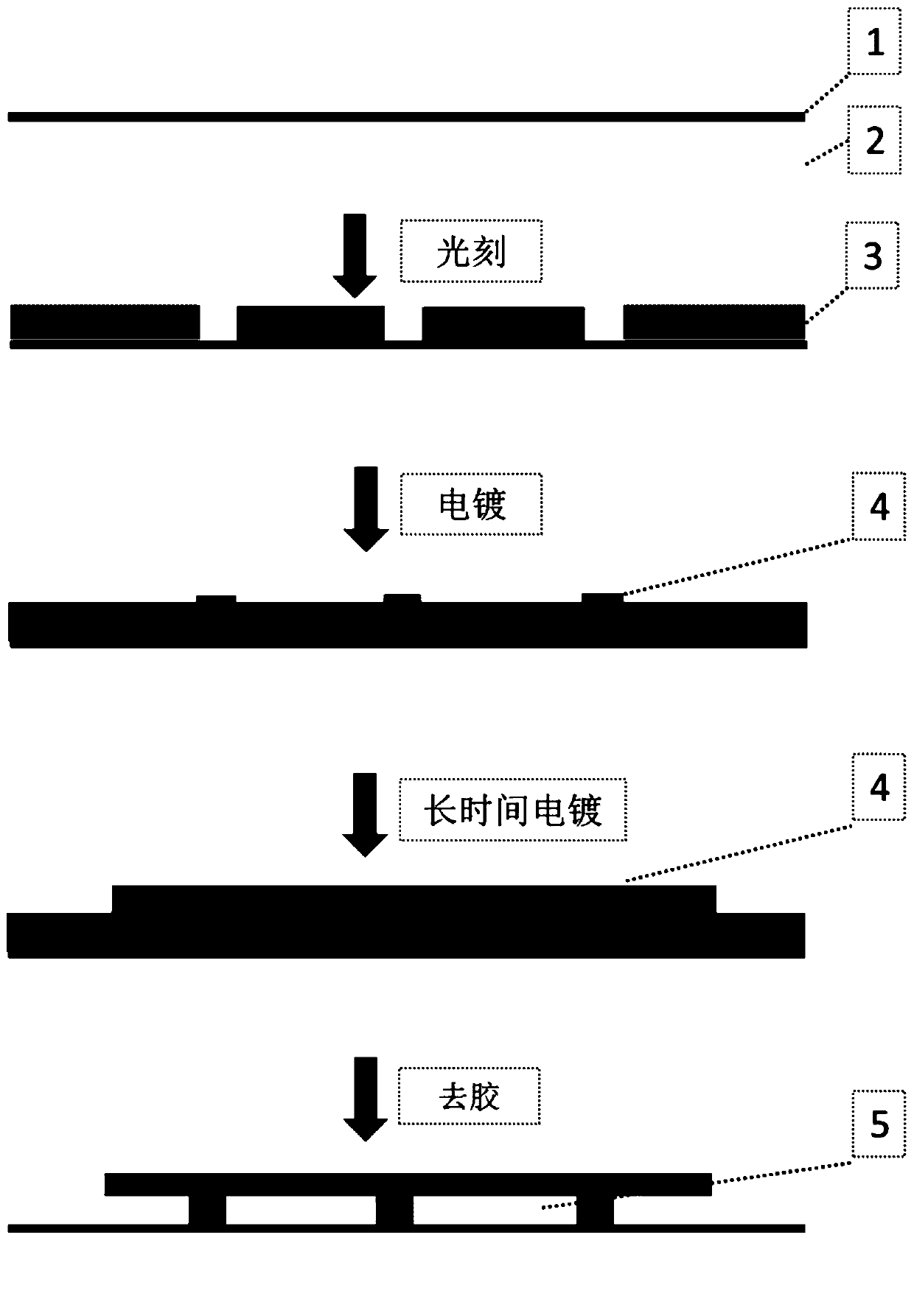

Method used

Image

Examples

Embodiment 1

[0027] (1) The substrate material is glass;

[0028] (2) On the glass substrate, the metal film deposited by electron beam evaporation coating is: 3 nanometers of titanium and 5 nanometers of gold;

[0029] (3) Use electron beam lithography to carry out photolithography to form patterning on the metal film, specifically: first spin 120 nanometers of thickness to coat photoresist PMMA, and prepare predetermined pattern by exposure and development;

[0030] (4) Electroplating filling photolithography pattern: electroplating by square wave pulse method, voltage is 10V, duty cycle is 20%, current is 0.001A, time is 10 minutes;

[0031] (5) electroplating growth gold film: adopt square wave pulse method electroplating, voltage is 10V, duty ratio is 80%, electric current is 0.01A, time is 5 minutes;

[0032] (6) Soak the substrate in an acetone solution to remove residual photoresist; form a cavity-coupled resonant surface plasmon metamaterial with a metal-air dielectric layer-meta...

Embodiment 2

[0034] (1) The substrate material is glass;

[0035] (2) On the glass substrate, the metal film deposited by electron beam evaporation coating is: 3 nanometers of chromium and 5 nanometers of silver;

[0036] (3) Use electron beam lithography to carry out photolithography to form patterning on the metal film, specifically: first spin 120 nanometers of thickness to coat photoresist PMMA, and prepare predetermined pattern by exposure and development;

[0037] (4) Electroplating filling photolithographic pattern: electroplating by square wave pulse method, voltage is 20V, duty cycle is 50%, current is 0.001A, time is 5 minutes;

[0038] (5) electroplating growth gold film: adopt square wave pulse method electroplating, voltage is 20V, duty cycle is 50%, electric current is 0.001A, time is 10 minutes;

[0039] (6) Soak the substrate in an acetone solution to remove residual photoresist; form a cavity-coupled resonant surface plasmon metamaterial with a metal-air dielectric layer-...

Embodiment 3

[0041] (1) The substrate material is glass;

[0042] (2) Depositing an indium tin oxide thin film on a glass substrate with an evaporation coating, the thickness is between 5-20 nanometers;

[0043] (3) Use a UV lithography machine to perform photolithography to form a pattern, specifically: first spin-coat a 150-nanometer UV photoresist, and prepare a predetermined pattern through exposure and development;

[0044] (4) Electroplating and filling photolithographic patterns: square wave pulse method is used for electroplating, the voltage is 10V, the duty cycle is 20%, the current is 0.01A, and the time is 15 minutes;

[0045] (5) Gold film grown by electroplating: the voltage is 80V, the duty cycle is 20%, the current is 0.01A, and the time is 45 minutes;

[0046] (6) The substrate is immersed in an acetone solution to remove residual photoresist; a cavity-coupled resonant surface plasmon metamaterial with a metal-air dielectric layer-metal structure is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com