Grid-line-free and undoped-contact based monocrystalline silicon heterojunction solar cell

A technology for solar cells and monocrystalline silicon, applied in the field of solar photovoltaic, can solve the problems of complex process, limit battery open-circuit voltage and short-circuit current, and high cost, and achieve the effects of simple structure design, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

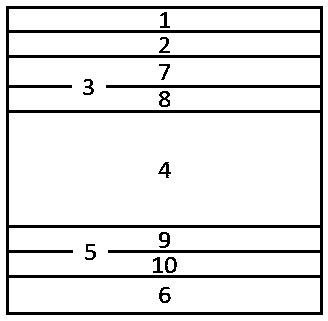

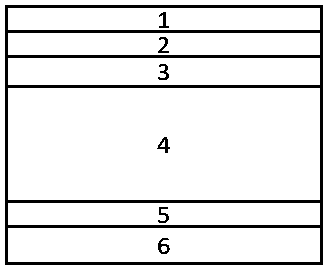

[0034]The anti-reflection film 1 is set to be molybdenum oxide with a thickness of 50 nm; the ultra-thin metal film 2 is an alloy film mixed with aluminum / silver in a ratio of 1:10, and the thickness is 5 nm; the hole selective contact 3 includes a hole selective film 7 and the first passivation film 8 are respectively 10 nm thick molybdenum oxide and 1 nm thick silicon oxide; the thickness of single crystal silicon 4 is 10 μm; the electron selective contact 5 includes the second passivation film 9 and the electron selective The permanent thin film 10 is respectively 1 nm thick silicon oxide and 1 nm thick lithium fluoride; the back electrode 6 is made of aluminum with a thickness of 100 nm.

[0035] On the basis of cleaning the single crystal silicon 4, silicon oxide can be deposited as the first passivation film 8 and the second passivation film 9 by using the atomic layer deposition method, and then by thermal evaporation method, on one surface of the single crystal silicon ...

Embodiment 2

[0037] The anti-reflection film 1 is set to be molybdenum oxide with a thickness of 50 nm; the ultra-thin metal film 2 is an aluminum / silver double-layer film with a thickness ratio of 1:5 and a thickness of 6 nm; the hole selective contact 3 is chromium oxide with a thickness of 20 nm; the thickness of monocrystalline silicon 4 is 50 μm, and the upper and lower surfaces are provided with pyramid textured light-trapping structures; the electronic selective contact 5 is titanium oxide, with a thickness of 1 nm; the back electrode 8 is a calcium / aluminum double-layer film with a thickness ratio of The ratio is 1:20 and the thickness is 100 nm.

[0038] By selecting different materials and setting different film thickness parameters, the single crystal silicon heterojunction solar cell based on no gate lines and no doped contacts of the present invention can be flexibly designed, and can be prepared by using a variety of different film deposition methods Batteries, including but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com