PCB taking graphene-metal composite material as conductive circuit, manufacturing method of PCB and motor

A technology of metal composite materials and conductive lines, applied in the direction of metal pattern materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of restricting the weight of PCB, the gap of copper conductive lines, and large copper conductive lines, so as to reduce the total Weight, broaden the PCB application market, the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

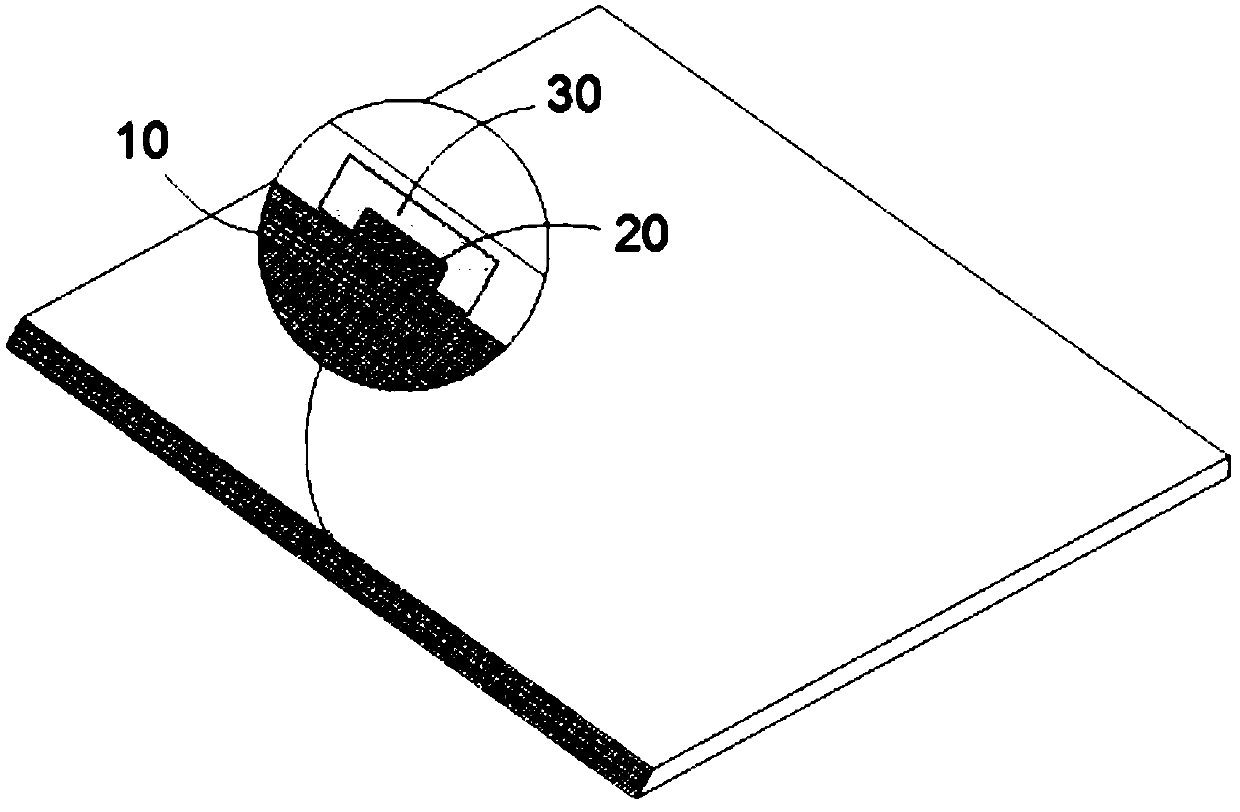

[0044] see figure 1As shown, the present embodiment provides a PCB with a graphene-metal composite material as a conductive circuit, and the PCB includes one or more layers of substrate boards 10 and bottom conductive wires 20 on the surface of the substrate board 10 , the surface of the bottom conductive wire 20 is covered with a graphene-metal composite material layer 30 . The graphene-metal composite material layer 30 serves as a conductive circuit.

[0045] For example, the metal element in the graphene-metal composite material layer is copper, zinc, chromium, gallium, indium, iron, nickel, silver, platinum or gold, or the metal element includes any two or more of the above elements. two or more elements.

[0046] For example, the metal element in the graphene-metal composite material layer is copper, and the graphene-metal composite material is a composite material containing graphene in copper.

[0047] For example, the bottom conductive wires 20 may be copper wires. ...

Embodiment 2

[0050] This embodiment provides a method for preparing the PCB described in Embodiment 1, the method specifically comprising:

[0051] S1, making a substrate plate, the surface of the substrate plate is covered with metal foil;

[0052] S2, etching the metal foil into bottom conductive wires;

[0053] S3, dispersing the graphene oxide in the ionic liquid, the ionic liquid contains metal ions;

[0054] S4, using the ionic liquid as the electroplating solution, using the underlying conductive wire on the surface of the substrate as the cathode substrate, and depositing a graphene-metal composite coating on the cathode substrate by a current control pulse, the current The control pulse includes a positive-going pulse period in which the current is negative at the deposition surface, and a pause period in which the current is zero; or,

[0055] The ionic liquid is used as the electroplating solution, and the underlying conductive wire on the surface of the substrate plate is use...

specific Embodiment approach 1

[0058] Specific embodiment 1: select choline chloride and ethylene glycol that molar ratio is 1:1 for use as ionic liquid; Contain graphene oxide in this ionic liquid, the concentration of graphene oxide is 0.2g / L; Contain in this ionic liquid Copper ions, the concentration of copper ions is 1 mM.

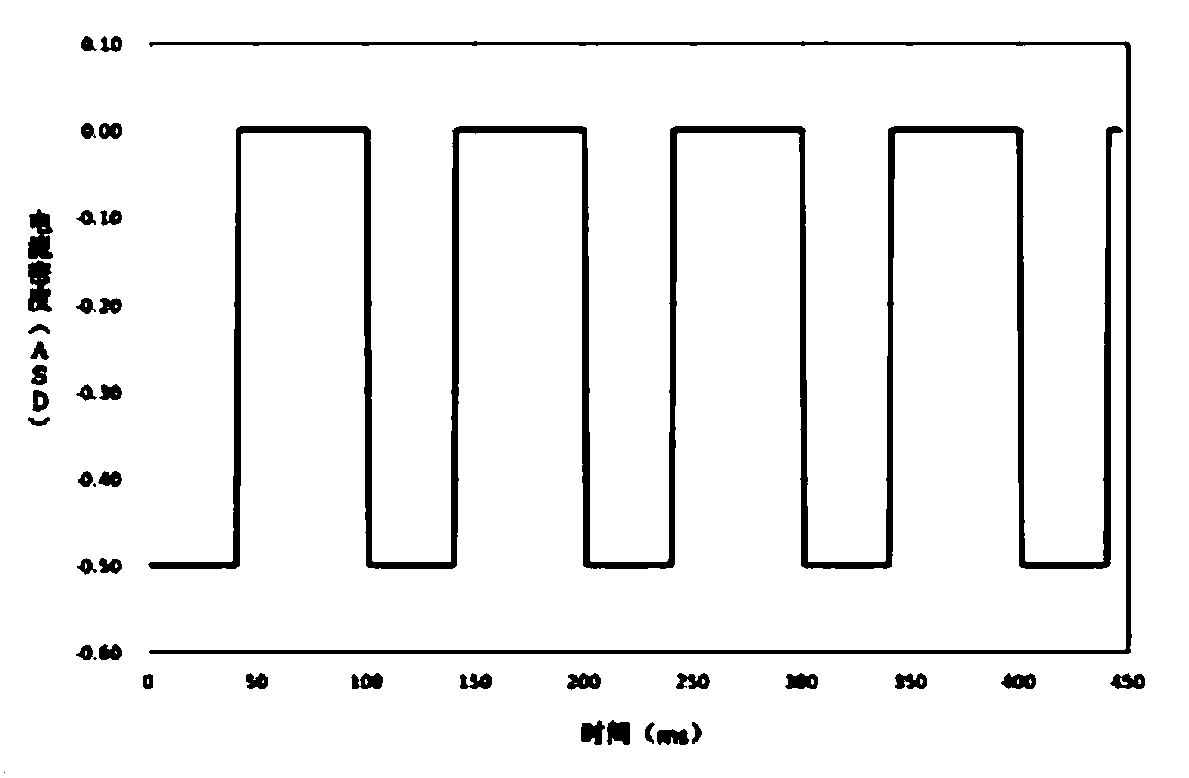

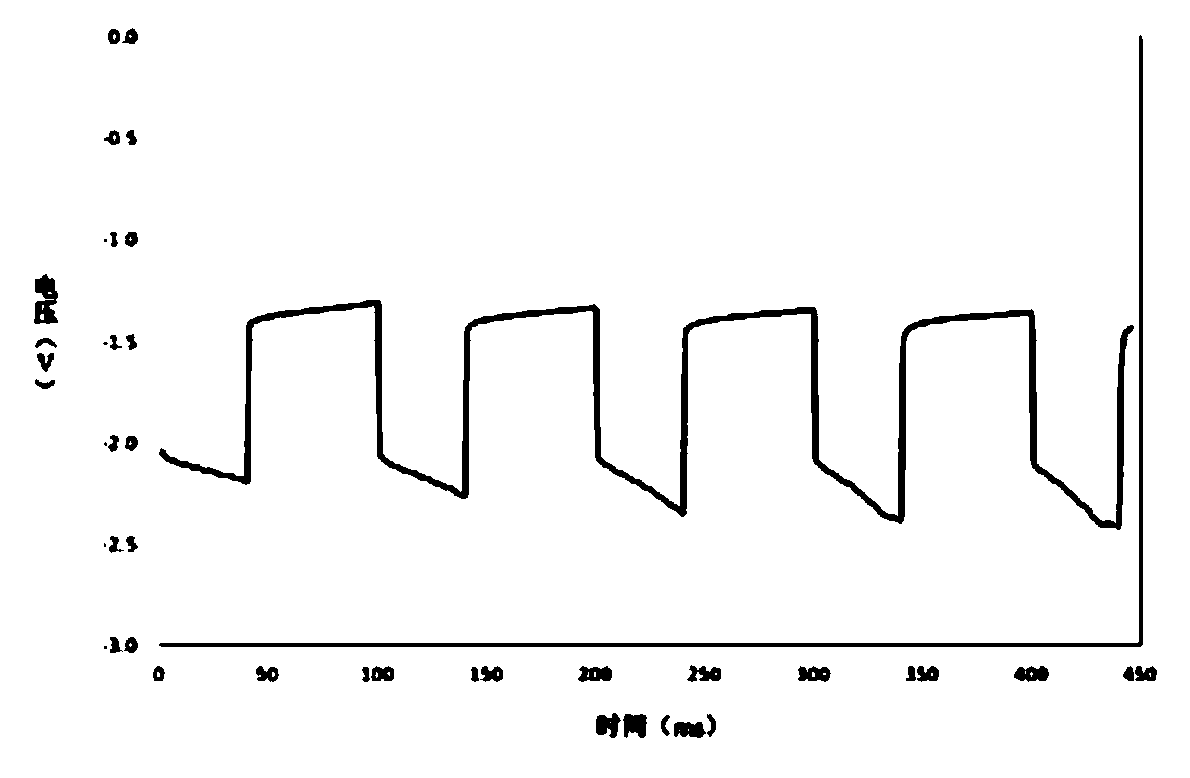

[0059] The above-mentioned ionic liquid is used as the electroplating solution, the bottom conductive wire of the base plate is selected as the cathode substrate, and the platinum sheet is selected as the anode, and a power supply that can provide pulses is used to apply current-controlled pulses, wherein the duration of the positive pulse period The time was 40 ms, the current density was -0.5ASD, and the duration of the pause period was 60 ms. The ionic liquid was stirred without a stirrer during plating.

[0060] During pulse plating, current density and corresponding voltage changes, see figure 2 and image 3 shown. For the macroscopic picture of the graphene composite coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com