Preparation method of high-tensile amide benzene ring emulsion polymer with core-shell structure

A technology of emulsion polymer and tensile amide, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of poor waterproof performance and aging resistance, general adhesion, etc., and achieve improvement Performance, improvement of penetration energy and adhesion, and strong internal bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

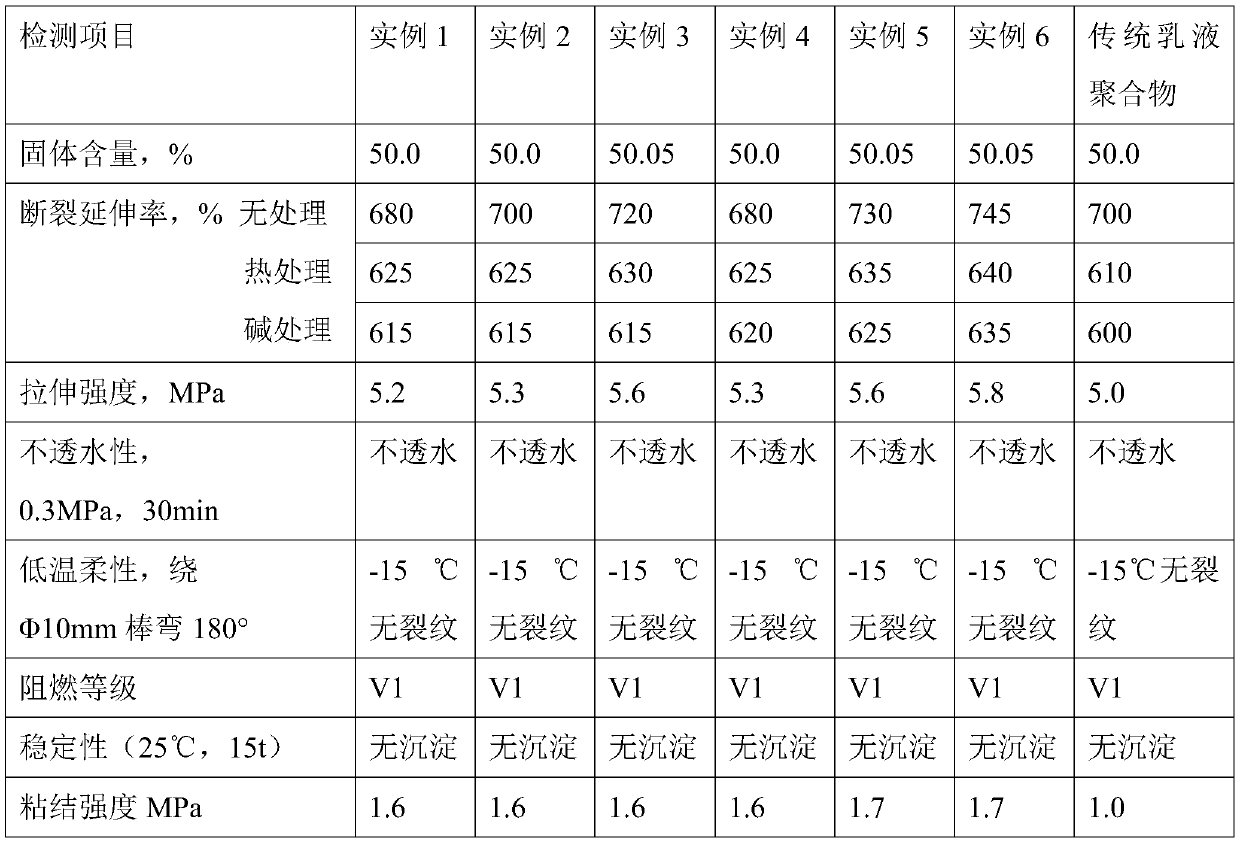

Examples

example 1

[0052] A method for preparing a core-shell structure high tensile amide benzene emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0053] 3.5 parts of N,N-dimethylacrylamide:

[0054] 1-Phenylvinylboronic acid: 15 parts

[0055] Dicyclohexyl peroxydicarbonate: 0.30 parts

[0056] Ammonium hypophosphite: 0.55 parts

[0057] 4-vinylbenzene)sulfonamide: 10 parts

[0058] Hydroxyethyl acrylate: 230 parts

[0059] 4-methoxy-2-vinylaniline: 160 parts

[0060] 3-Methyl-1-vinyl-2-azepanone: 32 parts

[0061] Lauryl peroxide: 1.5 parts

[0062] Hydrogen peroxide: 1.5 parts

[0063] Ascorbic acid: 2 parts

[0064] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 5 parts

[0065] Ethylene glycol methacrylate phosphate: 12 parts

[0066] Diethanolamine: 1.6 parts

[0067] Potassium hydroxide: 2.4 parts

[0068] The composition of trifluoroethyl acr...

example 2

[0076] A method for preparing a core-shell structure high tensile amide benzene emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0077] 3.5 parts of N,N-dimethylacrylamide:

[0078] 1-Phenylvinylboronic acid: 15 parts

[0079] Dicyclohexyl peroxydicarbonate: 0.30 parts

[0080] Ammonium hypophosphite: 0.55 parts

[0081] Composition of 4-vinylbenzamide and cinnamic amide with a mass ratio of 1:1: 10 parts

[0082] Hydroxyethyl acrylate: 230 parts

[0083] 4-methoxy-2-vinylaniline: 160 parts

[0084] 3-Methyl-1-vinyl-2-azepanone: 32 parts

[0085] Lauryl peroxide: 1 part

[0086] Hydrogen peroxide: 2 parts

[0087] Composition of ascorbic acid and sodium formaldehyde sulfoxylate with a mass ratio of 1:1: 2 parts

[0088] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 5 parts

[0089] Composition of methacryloxyethyl phosphate and ethyle...

example 3

[0100] A method for preparing a core-shell structure high tensile amide benzene emulsion polymer, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and the components and process parameters are as follows:

[0101] 3.5 parts of N,N-dimethylacrylamide:

[0102] 1-Phenylvinylboronic acid: 15 parts

[0103] Dicyclohexyl peroxydicarbonate: 0.30 parts

[0104] Ammonium hypophosphite: 0.55 parts

[0105] (4-vinylbenzene)sulfonamide: 10 parts

[0106] Hydroxyethyl acrylate: 230 parts

[0107] 4-methoxy-2-vinylaniline: 160 parts

[0108] 3-Methyl-1-vinyl-2-azepanone: 32 parts

[0109] Lauryl peroxide: 1.5 parts

[0110] Hydrogen peroxide: 2 parts

[0111] Composition of ascorbic acid and sodium formaldehyde sulfoxylate with a mass ratio of 1:1: 2 parts

[0112] Hydroxyethyl Phthalic Anhydride Dimethacrylate: 5 parts

[0113] Composition of methacryloxyethyl phosphate and ethylene glycol methacrylate phosphate with a mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com