Preparation and applications of ultralow-water-content ceramic slurry for lithium ion battery

A lithium-ion battery, ceramic slurry technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as battery capacity decline, battery pressure increase, affecting battery performance, etc., to reduce the number and water content. , the effect of small surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

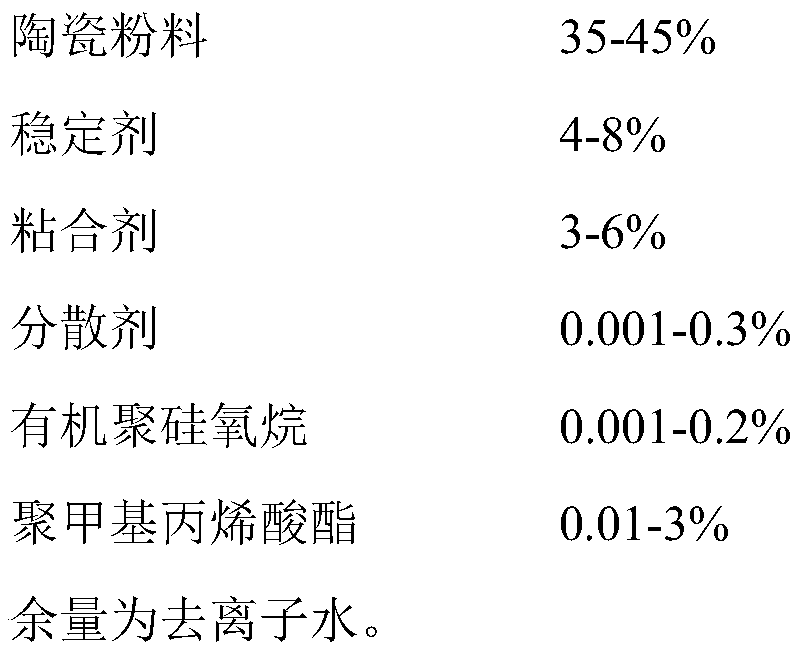

[0030] A kind of ultra-low water content ceramic slurry for lithium ion battery, comprises the raw material of following weight percent:

[0031]

[0032]

[0033] The ceramic powder is composed of a specific surface area of 2m 2 / g of alumina, the specific surface area is 3m 2 / g of magnesium oxide and a specific surface area of 2.5m 2 / g of boehmite is a mixture composed of 0.8:1.0:0.8 by weight.

[0034] The specific surface area is 2m 2 / g of alumina is prepared by the following steps:

[0035] 1) Using a wet ball milling process to grind conventional α-crystal form calcined alumina into alumina powder with a particle size of less than 1 μm, and set aside;

[0036] 2) Using spray drying to dry the alumina powder obtained in step 1) under the condition of 170° C., remove moisture, and set aside;

[0037] 3) The alumina powder dried in step 2) is placed under the condition of 1200° C. for calcination for 60 minutes, and finally the calcined alumina powder is gro...

Embodiment 2

[0047] A kind of ultra-low water content ceramic slurry for lithium ion battery, comprises the raw material of following weight percent:

[0048]

[0049] The ceramic powder is composed of a specific surface area of 4m 2 / g of alumina, the specific surface area is 4m 2 / g of magnesium oxide and a specific surface area of 3m 2 / g of boehmite is a mixture composed of 0.9:1.0:0.9 by weight.

[0050] The specific surface area is 4m 2 / g of alumina is prepared by the following steps:

[0051] 1) Using a wet ball milling process to grind conventional α-crystal form calcined alumina into alumina powder with a particle size of less than 1 μm, and set aside;

[0052] 2) Use spray drying to dry the alumina powder obtained in step 1) under the condition of 175° C., remove moisture, and set aside;

[0053] 3) The alumina powder dried in step 2) is placed under the condition of 1250° C. for calcination for 75 minutes, and finally the calcined alumina powder is ground by a dry b...

Embodiment 3

[0063] A kind of ultra-low water content ceramic slurry for lithium ion battery, comprises the raw material of following weight percent:

[0064]

[0065] The ceramic powder is composed of a specific surface area of 6m 2 / g of alumina, the specific surface area is 5m 2 / g of magnesium oxide and a specific surface area of 3.5m 2 / g of boehmite is a mixture composed of a weight ratio of 1.0:1.0:1.0.

[0066] The specific surface area is 6m 2 / g of alumina is prepared by the following steps:

[0067] 1) Using a wet ball milling process to grind conventional α-crystal form calcined alumina into alumina powder with a particle size of less than 1 μm, and set aside;

[0068] 2) Using spray drying to dry the alumina powder obtained in step 1) under the condition of 180° C., remove moisture, and set aside;

[0069] 3) The alumina powder dried in step 2) is placed at 1300° C. for calcination for 90 minutes, and finally the calcined alumina powder is ground by a dry ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com