Preparation method of tetraethylammonium hydroxide

A technology of tetraethylammonium hydroxide and equipment, applied in chemical instruments and methods, electrodes, electrodialysis, etc., can solve the problems of no obvious advantage in production cost, many materials, complicated process, etc., and reduce the use of membranes , high concentration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method for tetraethylammonium hydroxide, comprising the following steps:

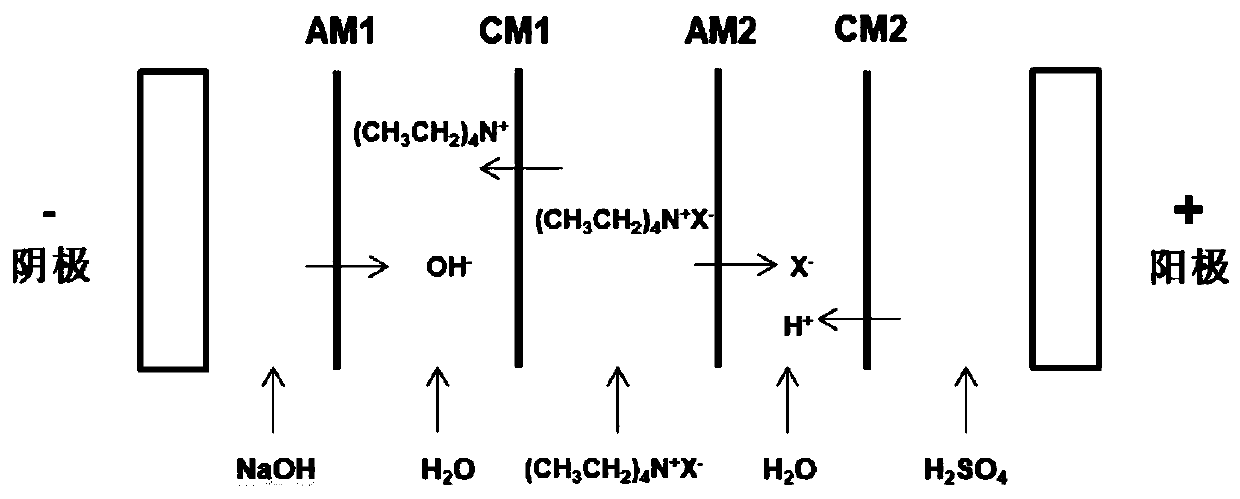

[0044] (1) Prepare the electrodialysis equipment: the assembly structure from the cathode to the anode is as follows: anion exchange membrane AM1, cation exchange membrane CM1, anion exchange membrane AM2, and cation exchange membrane CM2, thereby forming a cathode chamber, a product chamber, a feed liquid chamber, Acid chamber, anode chamber;

[0045] Among them, the cathode and anode are iridium-tantalum-coated titanium electrodes;

[0046] Anion exchange membrane AM1 is ASV membrane; anion exchange membrane AM2 is AHT membrane;

[0047] The cation exchange membrane CM1 is an OCM membrane; the cation exchange membrane CM2 is a CMV membrane;

[0048] (2) Add the corresponding solutions of the five compartments, open the circulation, remove the air, adjust the flow rate of each compartment to 400L / h, electrolyze, and the current density is 800A / m 2 , and open the feeding pump of ...

Embodiment 2

[0052] A preparation method for tetraethylammonium hydroxide, comprising the following steps:

[0053] (1) Prepare the electrodialysis equipment: the assembly structure from the cathode to the anode is as follows: anion exchange membrane AM1, cation exchange membrane CM1, anion exchange membrane AM2, and cation exchange membrane CM2, thereby forming a cathode chamber, a product chamber, a feed liquid chamber, Acid chamber, anode chamber;

[0054] Among them, the cathode and anode are iridium-tantalum-coated titanium electrodes;

[0055] Anion exchange membrane AM1 is ASV membrane; anion exchange membrane AM2 is AHT membrane;

[0056] The cation exchange membrane CM1 is an OCM membrane; the cation exchange membrane CM2 is a CMV membrane;

[0057] (2) Add the corresponding solutions of the five compartments respectively, open the circulation, remove the air, adjust the flow rate of each compartment to 300L / h, electrolyze, and the current density is 900A / m 2 , and open the feedi...

Embodiment 3

[0061] A preparation method for tetraethylammonium hydroxide, comprising the following steps:

[0062] (1) Prepare the electrodialysis equipment: the assembly structure from the cathode to the anode is as follows: anion exchange membrane AM1, cation exchange membrane CM1, anion exchange membrane AM2, and cation exchange membrane CM2, thereby forming a cathode chamber, a product chamber, a feed liquid chamber, Acid chamber, anode chamber;

[0063] Among them, the cathode and anode are iridium-tantalum-coated titanium electrodes;

[0064] Anion exchange membrane AM1 is ASV membrane; anion exchange membrane AM2 is AHT membrane;

[0065] The cation exchange membrane CM1 is an OCM membrane; the cation exchange membrane CM2 is a CMV membrane;

[0066] (2) Add the corresponding solutions of the five compartments respectively, open the circulation, remove the air, adjust the flow rate of each compartment to 500L / h, electrolyze, and the current density is 800A / m 2 , and open the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com