Preparation method of anticorrosive aluminum profile

A technology for aluminum profiles and aluminum alloy profiles, applied in anti-corrosion coatings, metal material coating processes, anodic oxidation, etc., can solve problems such as corrosion, damage, and environmental pollution, and achieve good corrosion resistance, strong adhesion, and improved The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

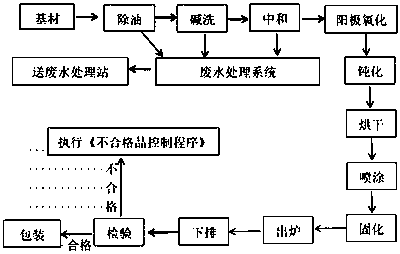

[0023] Embodiment one: if figure 1 Shown, a kind of preparation method of anticorrosion aluminum profile, it comprises the following steps:

[0024] S1. Degreasing: immerse the aluminum alloy workpiece in a degreasing solution containing 5% sulfuric acid by mass fraction and 2g / L emulsifier for 4 minutes at a temperature of 50°C;

[0025] S2. Alkali washing: The degreased aluminum alloy profile is immersed in the alkali solution with a concentration of sodium hydroxide of 50g / L and a temperature of 50°C for 5s, which can remove the oxide and dirt naturally formed on the surface of the aluminum alloy profile;

[0026] S3. Neutralization: immerse the aluminum alloy profile in a nitric acid solution with a concentration of 10%, soak for 20s at room temperature, and neutralize the nitric acid solution and sodium hydroxide solution;

[0027] S4. Anodizing: use a sulfuric acid solution with a concentration of 180g / L as the electrolyte for anodizing to form an anodic oxidation film ...

Embodiment 2

[0033] Embodiment two: a kind of preparation method of anticorrosion aluminum profile, it comprises the following steps:

[0034] S1. Degreasing: immerse the aluminum alloy workpiece in a degreasing solution containing 10% sulfuric acid by mass fraction and 3g / L emulsifier for 5 minutes at a temperature of 53°C;

[0035] S2. Alkali washing: The degreased aluminum alloy profile is immersed in the alkali solution with a concentration of sodium hydroxide of 100g / L and a temperature of 55°C for 43s, which can remove the oxides and dirt naturally formed on the surface of the aluminum alloy profile;

[0036] S3. Neutralization: immerse the aluminum alloy profile in a nitric acid solution with a concentration of 12%, soak for 22s at room temperature, and neutralize the nitric acid solution and sodium hydroxide solution;

[0037] S4. Anodizing: use a sulfuric acid solution with a concentration of 190g / L as the electrolyte for anodizing to form an anodic oxidation film on the surface o...

Embodiment 3

[0043] Embodiment three: a kind of preparation method of anticorrosion aluminum profile, it comprises the following steps:

[0044] S1. Degreasing: immerse the aluminum alloy workpiece in a degreasing solution containing 15% by mass of sulfuric acid and 5g / L of emulsifier for 6 minutes at a temperature of 55°C;

[0045] S2. Alkali washing: The degreased aluminum alloy profile is immersed in the alkali solution with a concentration of sodium hydroxide of 150g / L and a temperature of 60°C for 60s, which can remove the oxides and dirt naturally formed on the surface of the aluminum alloy profile;

[0046] S3. Neutralization: immerse the aluminum alloy profile in a nitric acid solution with a concentration of 15%, soak for 30s at room temperature, and neutralize the nitric acid solution and sodium hydroxide solution;

[0047] S4. Anodizing: use a sulfuric acid solution with a concentration of 200g / L as the electrolyte for anodizing to form an anodic oxidation film on the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com