Method for preparing micro-pore composite nanofiber membrane by electrostatic spinning and application

A composite nanofiber and electrospinning technology, which is applied in the direction of synthetic fiber, fiber type, fiber treatment, etc., can solve the problems of small proportion of functional effect components, general compatibility with polymers, etc., and achieve good carbon dioxide adsorption performance, adsorption The effect of good performance and large adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a microporous composite nanofiber membrane, specifically comprising the steps of:

[0041] 1. Synthesis of macroinitiators

[0042] Fully dissolve 16.36g of tert-butyl acrylate, 73ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 59.4mg of cuprous bromide into 30ml of N,N-dimethyl In methyl formamide, nitrogen gas was introduced for 30 minutes. Then add 57ul of ethyl 2-bromoisobutyrate, and react under nitrogen atmosphere at 60°C for 24h; : 1, v) Precipitation of the polymer in the mixed medium, vacuum drying to constant weight at 60 ° C, to obtain a macromolecular initiator of white powder;

[0043] 2. Synthesis of Diblock Polymers

[0044] Fully dissolve 12.48g of styrene, 28ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 45mg of cuprous bromide into 20ml of N,N-dimethylformamide During the process, nitrogen gas was introduced for 30 minutes. Then add 12.48g of the macromolecular initiator obtained in step 1, and react for 24h at ...

Embodiment 2

[0059] The difference between Example 2 and Example 1 is: the mass ratio of super-crosslinked microporous nanoparticles and polyvinyl alcohol in the microporous composite nanofiber membrane prepared by electrospinning in Example 2, that is, the super-crosslinked micropores are increased. The content of nanoparticles in the blend, so as to explore whether the increase of hypercrosslinked microporous nanoparticles can still be spun and the change of its pore properties.

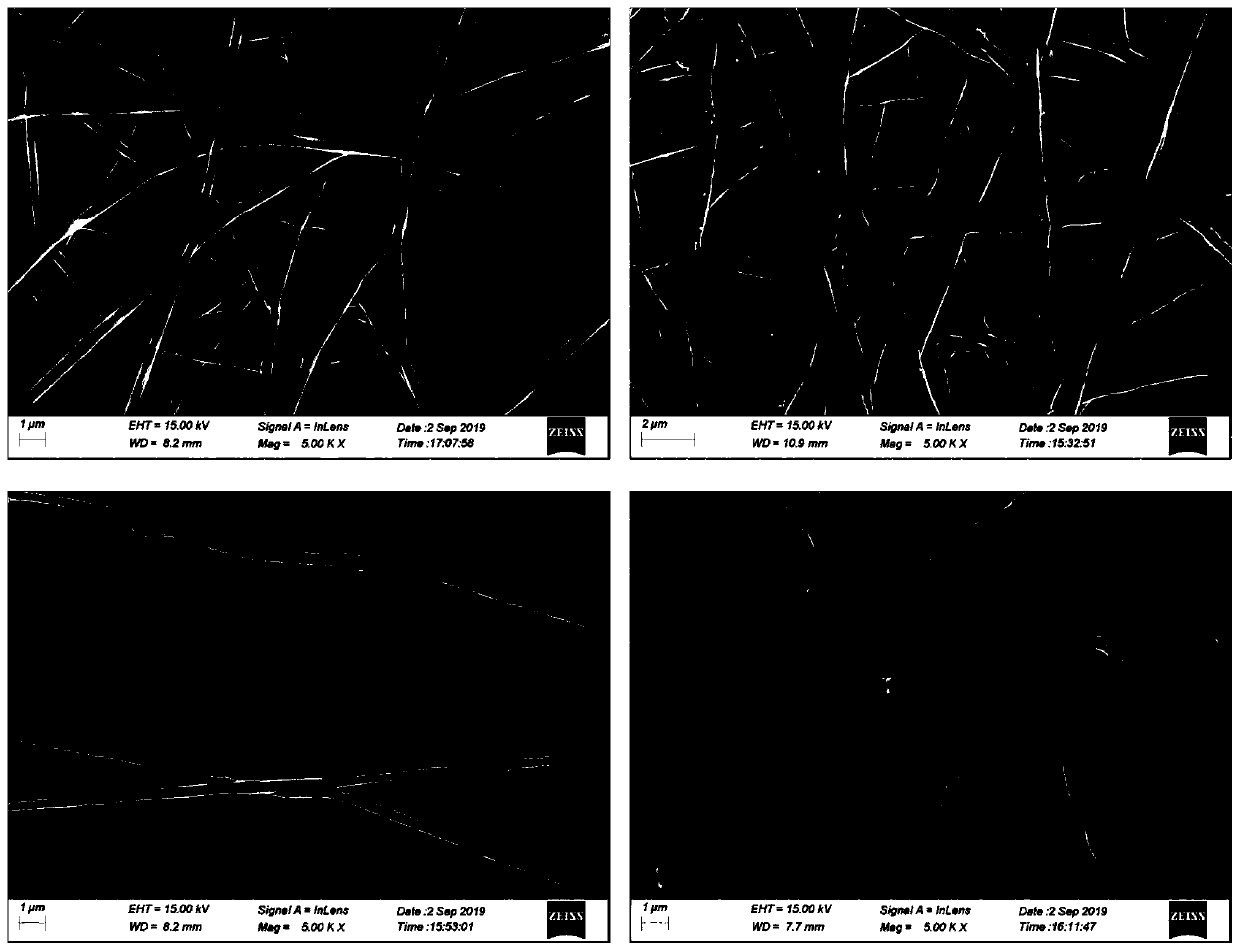

[0060] Such as Figure 7 As shown, from the FESEM topography images from A to D, it can be seen that the content of hypercrosslinked microporous nanoparticles is gradually increasing, but good fiber morphology can still be maintained, and the fiber diameter is decreasing.

[0061] Such as Figure 8 As shown, with the increase of hypercrosslinked microporous nanoparticles, the specific surface area of the microporous composite membrane increases.

[0062] Such as Figure 9 As shown, with the increase of hyp...

Embodiment 3

[0064] A method for preparing a microporous composite nanofibrous membrane, comprising the steps of:

[0065] 1. Synthesis of macroinitiators

[0066] Fully dissolve 15.16g of tert-butyl acrylate, 71ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 56.4mg of cuprous bromide into 30ml of N,N-dimethyl In methyl formamide, nitrogen gas was introduced for 30 minutes. Then add 59ul of ethyl 2-bromoisobutyrate, and react under nitrogen atmosphere at 60°C for 24h; : 1, v) Precipitation of the polymer in the mixed medium, vacuum drying to constant weight at 60 ° C, to obtain a macromolecular initiator of white powder;

[0067] 2. Synthesis of Diblock Polymers

[0068] Fully dissolve 13.48g of styrene, 29ul of N,N,N′,N″,N″-pentamethyldiethylenetriamine, and 47mg of cuprous bromide into 25ml of N,N-dimethylformamide During the process, nitrogen gas was introduced for 30 minutes. Then add 11.48g of the macromolecular initiator obtained in step 1, and react for 24h at 120°C in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com