Bone cartilage repairing bracket and preparation method thereof

A technology of osteochondral and cartilage, applied in the field of osteochondral repair scaffold and its preparation, can solve the problems of cartilage tissue easily surpassing the surrounding normal tissue, growing into the scaffold, cartilage hyperplasia, etc., and achieve the effect of avoiding cartilage hyperplasia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

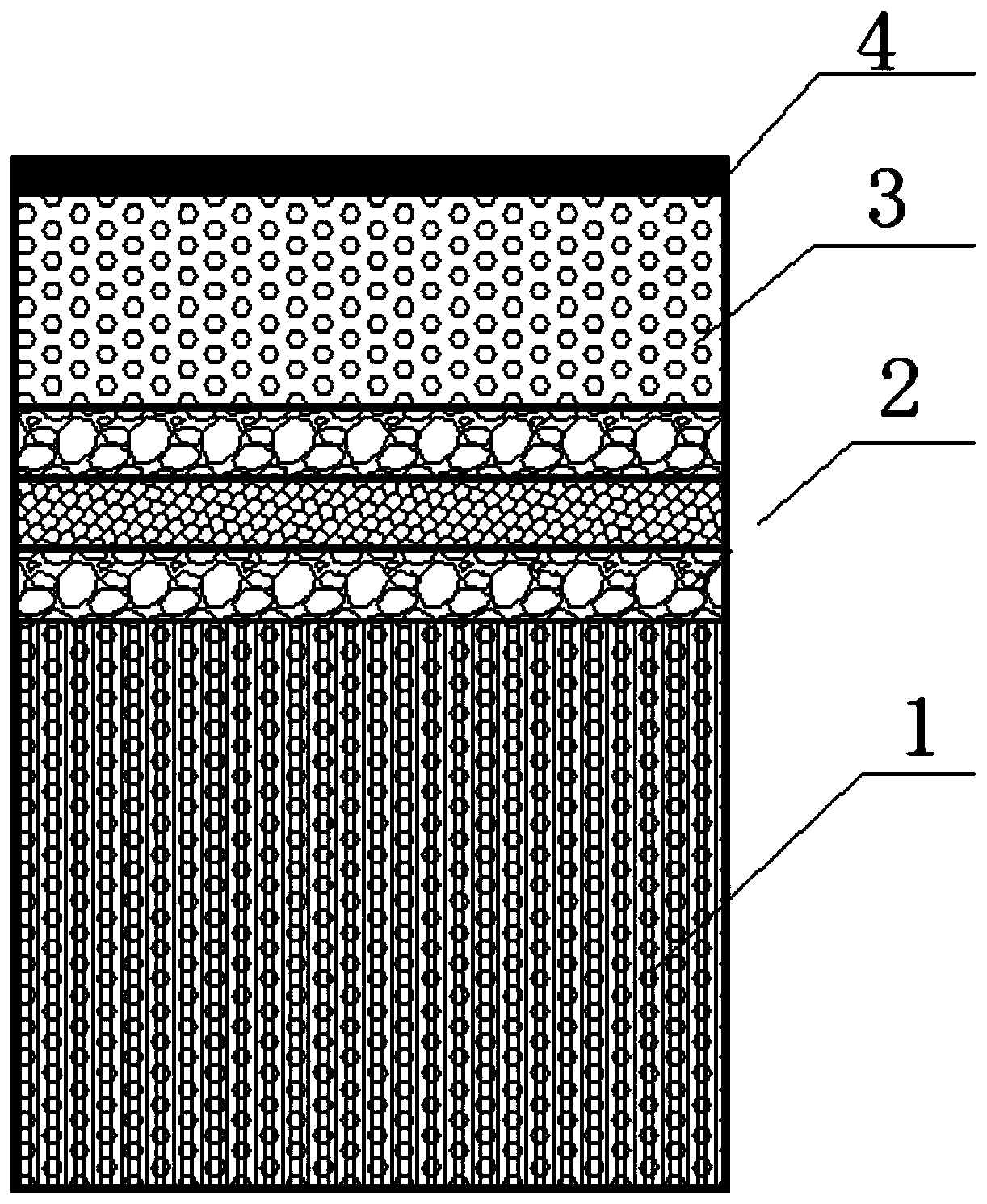

[0079] The embodiment of the present invention also discloses a method for preparing an osteochondral repair scaffold, which includes the following steps:

[0080] S10: preparing the subchondral bone layer, the calcified cartilage layer and the cartilage layer connected in sequence;

[0081] S20: forming a dense perichondrial layer on the surface of the cartilage layer away from the calcified cartilage layer.

[0082] In step S10, for the preparation of the subchondral bone layer, the calcified cartilage layer, and the cartilage layer that are sequentially connected, different preparation methods and different orders can be used.

[0083] In an embodiment of the present invention, first, polylactic acid (PLLA) is used to form a calcified cartilage layer by thermally induced phase separation. Then, a subchondral bone layer and a cartilage layer are formed on the surfaces of both sides of the calcified cartilage layer.

[0084] In this embodiment, in the thermally induced phase separatio...

Embodiment 1

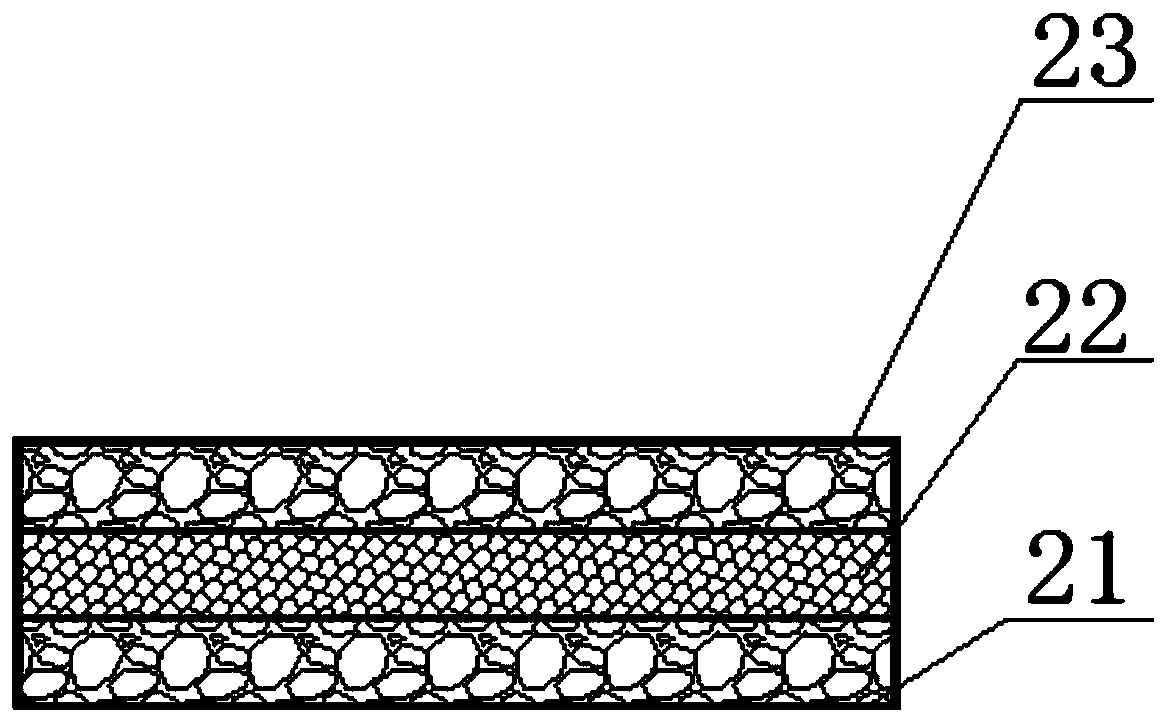

[0106] (1) Preparation of calcified cartilage layer

[0107] Prepare a PLLA solution with a concentration of 4% (g / 100ml) (PLLA viscosity average molecular weight is 100000), the solvent is tetrahydrofuran, and pour it into a mold with a layer of fructose microsphere porogen (porogen particle size 100μm-200μm) at the bottom In the process, immerse the porogen, and form a layer of PLLA solution on the porogen; then add a layer of porogen on the top of the PLLA solution layer (the particle size of the porogen is 100μm-200μm), and then add PLLA The solution is filled with the porogen, and then thermally induced phase separation at -20°C for 2 hours, and then the solvent is replaced with pure water three times, then lyophilized to obtain a calcified cartilage layer, and the calcified cartilage layer after lyophilization is placed in a UV / ozone machine Treat for 10min to enhance its hydrophilicity.

[0108] The calcified cartilage layer has two surface layers and a barrier layer locate...

Embodiment 2

[0122] (1) Preparation of calcified cartilage layer

[0123] In this embodiment, the preparation of the calcified cartilage layer is basically the same as that of Embodiment 1, except that in this embodiment, the thermally induced phase separation is performed at a temperature of -80° C. for 1 hour.

[0124] The resulting calcified cartilage layer has two surface layers and a barrier layer located between the two surface layers. In this embodiment, the PLLA solution immersed the porogen part to form two surface layers, the macropore diameter is 100-500μm, and the micropore diameter is 500nm-5μm; the PLLA solution layer is formed as a barrier layer, the pore size is 500nm-5μm .

[0125] (2) Preparation of subchondral bone layer

[0126] Preparation of metal frame

[0127] Use software to design the subchondral bone metal frame and print it with a three-dimensional printer. The material of the metal frame in this embodiment is magnesium alloy. The outer diameter of the metal frame is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com