Drug-loaded guided tissue regeneration membrane and preparation method thereof

A technology to guide tissue regeneration and drug loading, applied in medical science, surgery, etc., can solve few problems such as antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

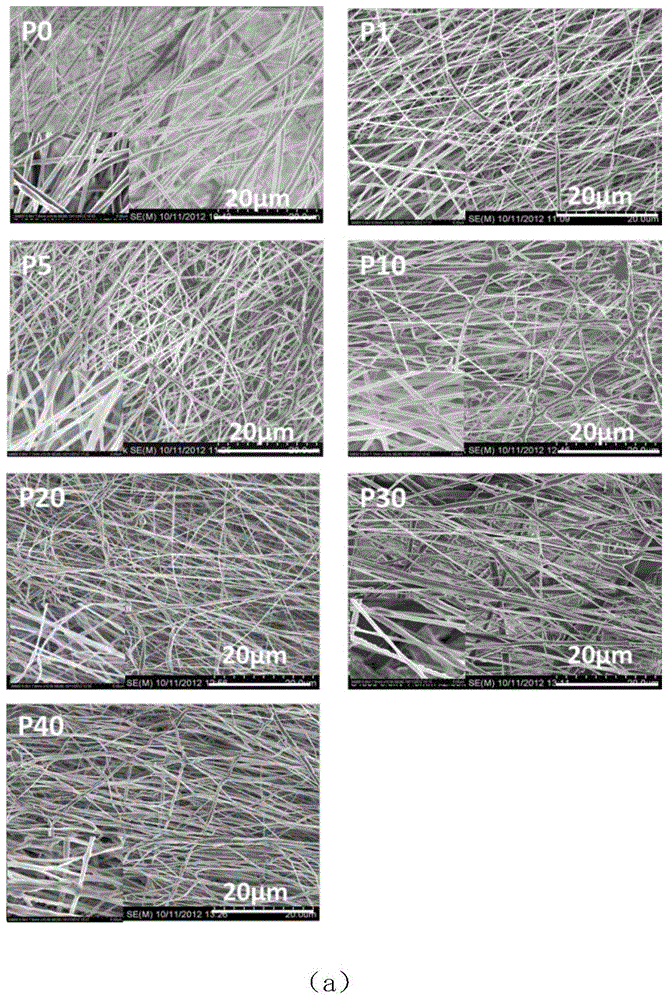

[0056] 1. Dissolve 2 g of polycaprolactone and 0.2 g of metronidazole in a mixed solvent of 7.2 g of DMF and 10.8 g of DCM, and stir magnetically at room temperature for 12 hours to obtain polycaprolactone with a concentration of 10% (w / w), metronidazole A spinning solution with a mass ratio of azole to polycaprolactone of 10%.

[0057] 2. Take the solution for electrospinning, use a stainless steel drum as the receiving device, the drum speed is 200rpm, the voltage is 10KV, the receiving distance is 16cm, the spinning liquid inlet rate is 4mL / h, and the spinning is 5h. A single-layer guided tissue regeneration membrane with a thickness of about 250 μm was obtained.

[0058] 3. Dry the obtained fiber membrane in a fume hood at room temperature for 72 hours to ensure that the residual solvent is fully volatilized.

Embodiment 2

[0060] 1. Dissolve polycaprolactone and metronidazole in a mixed organic solvent of DCM / DMF=7:3, and stir magnetically at room temperature for 12 hours to obtain a concentration of polycaprolactone of 20%, and the concentration of metronidazole and polycaprolactone The spinning solution with a mass ratio of 50%;

[0061] 2. Electrospinning at room temperature, with a stainless steel drum as the receiving device, the drum rotation rate is 600rpm, the spinning solution flow rate is 3mL / h, the voltage is 12kV, the receiving distance is 15cm, and the spinning is 5h, and a single-layer guide with a thickness of about 200μm is obtained. Tissue regeneration membrane.

[0062] 3. Dry the obtained fiber membrane in a fume hood at room temperature for 72 hours to fully volatilize the residual solvent.

Embodiment 3

[0064] 1. Dissolve 1.5g of polycaprolactone and 0.3g of tetracycline hydrochloride in 13.5g of trifluoroethanol, and magnetically stir at room temperature for 12 hours to obtain solution A;

[0065] 2. Dissolve 1.5g of polylactic acid and 0.3g of tetracycline hydrochloride in 13.5g of trifluoroethanol, and magnetically stir at room temperature for 12 hours to obtain solution B;

[0066] 3. Mix solution A and solution B, and magnetically stir for 12 hours to obtain a spinning solution with a mass ratio of polycaprolactone and polylactic acid of 1:1, a polymer concentration of 10%, and a mass ratio of drug to polymer of 20%. C;

[0067] 4. Electrospinning with spinning solution C at room temperature, with a stainless steel drum as the receiving device, the rotation rate of the drum is 200rpm, the flow rate of the spinning solution is 2mL / h, the voltage is 13kV, the receiving distance is 20cm, and the spinning time is 10h to obtain a thickness of 250μm Left and right monolayer e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com