Method for preparing guided tissue regeneration membrane through combination of electrostatic spinning and electrostatic spraying

A technology that guides tissue regeneration and electrostatic spraying. It is used in electrospinning, textiles and papermaking, and pharmaceutical formulations. It can solve unseen problems, achieve good biological activity and biodegradability, regulate cell morphology, and excellent permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

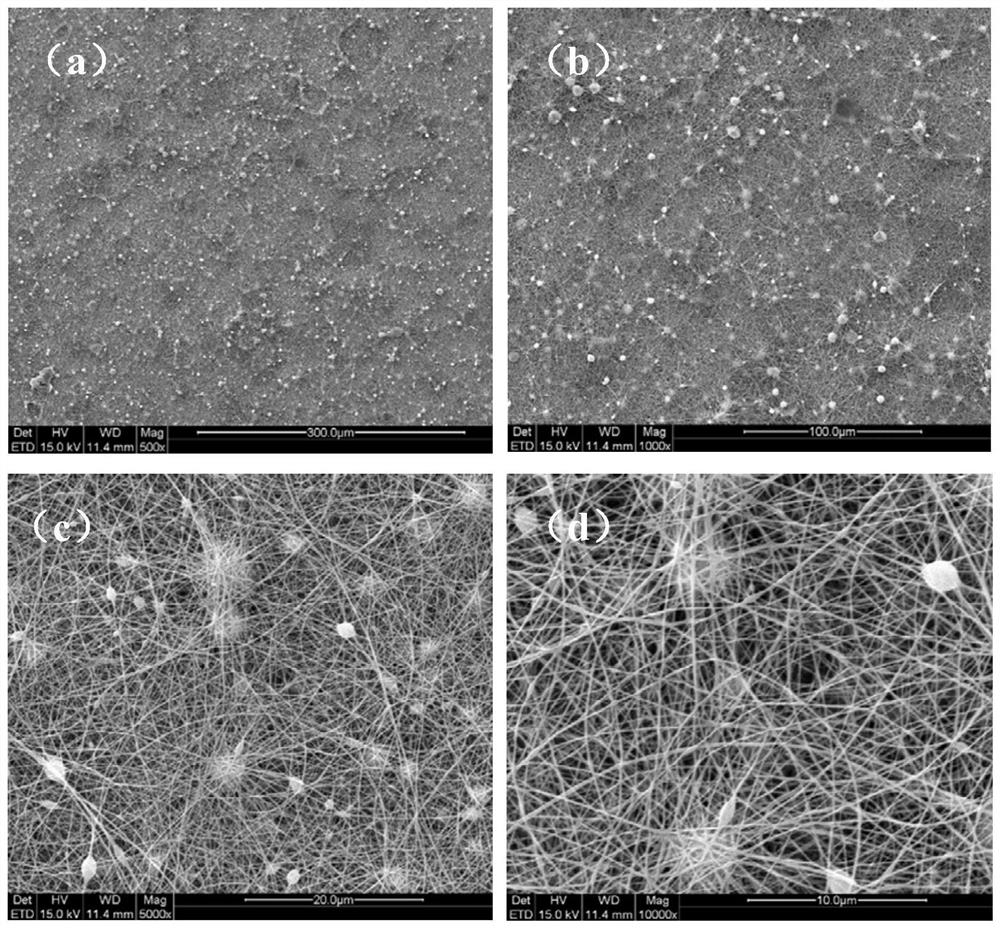

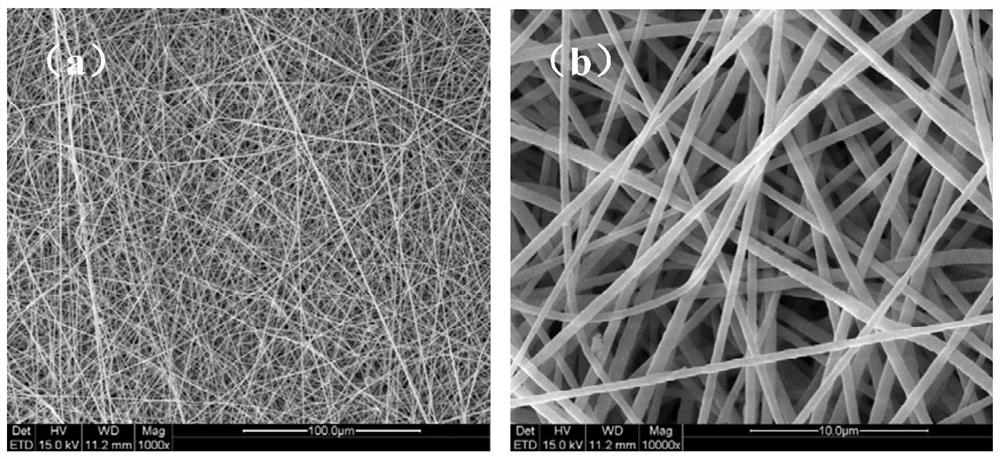

Image

Examples

preparation example Construction

[0071] 1. Preparation of Mineralized Collagen Powder

[0072] 1.1. Dissolve type I collagen in any one of hydrochloric acid, nitric acid or acetic acid to prepare an acid solution of type I collagen. The concentration of type I collagen contained in the prepared type I collagen acid solution is 0.01-0.2g / mL;

[0073] 1.2. Add calcium salt solution dropwise to the type I collagen acid solution, wherein the amount of calcium ions added is 0.1-2 mol of calcium ions corresponding to each gram of type I collagen;

[0074] 1.3. Add phosphoric acid solution dropwise in the solution obtained in step 1.2, wherein the molar ratio of the amount of phosphate ions added to the amount of calcium ions added in step 1.2 is Ca / P=1 / 1~2 / 1;

[0075] 1.4. Add NaOH solution dropwise to the solution obtained in step 1.3 to form a mixed solution, and adjust the pH value to 6-8;

[0076] 1.5. After the mixed solution obtained in step 1.4 was left to stand for 4-12 hours, the precipitate was centr...

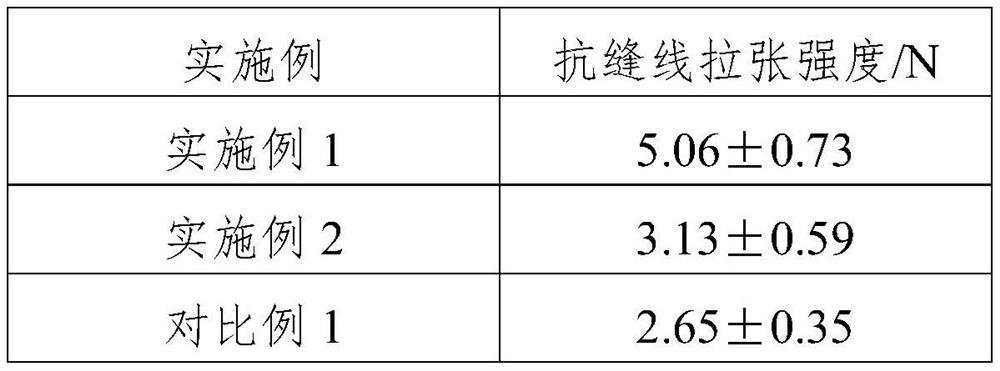

Embodiment 1

[0105] 1. Preparation of Mineralized Collagen Powder

[0106] 1.1. Dissolve type I collagen in hydrochloric acid, and the concentration of type I collagen contained in the prepared type I collagen acid solution is 0.1g / mL;

[0107] 1.2. Add a calcium salt solution dropwise to the type I collagen acid solution, wherein the amount of calcium ions added is 1 mol of calcium ions corresponding to each gram of type I collagen;

[0108] 1.3, drop phosphoric acid solution in the solution gained in step 1.2, wherein the mol ratio of the addition of phosphate ions to the addition of calcium ions in step 1.2 is Ca / P=1.5 / 1;

[0109] 1.4. Add NaOH solution dropwise to the solution obtained in step 1.3 to form a mixed solution, and adjust the pH value to 6.5;

[0110] 1.5. After the mixed solution obtained in step 1.4 was left to stand for 8 hours, the precipitate was centrifuged at a speed of 4000 r / min, and then air-dried at 60°C for 60 hours to obtain mineralized collagen particles; ...

Embodiment 2

[0138] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0139] In the preparation of type I collagen electrospinning solution in step 2.2:

[0140] Using trifluoroacetic acid as a solvent, weigh type Ⅰ collagen and add it into it, stir and dissolve overnight, to prepare 8w / v% type Ⅰ collagen electrospinning solution.

[0141] In the preparation of the nano-mineralized collagen electrostatic spray liquid in step 2.3:

[0142] Weigh the mineralized collagen powder and add it to methanol solution (methanol water solution with a volume percentage of 35%) to obtain a 6w / v% suspension, and ultrasonically treat the suspension at a frequency of 20kHz for 1h to obtain mineral Collagen electrostatic spray solution.

[0143] In the preparation of the rough layer in step 3.3:

[0144] Fix the syringe containing the mineralized collagen electrostatic spray solution on the micro-syringe pump. The inner diameter of the syringe is 14.9 mm, and each is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com