A kind of preparation method of the copper-cobalt base catalyst that is used for synthesis gas to make low-carbon alcohol

A catalyst and low-carbon alcohol technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of low alcohol selectivity and low activity, and achieve high activity, simple process, and high load. dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

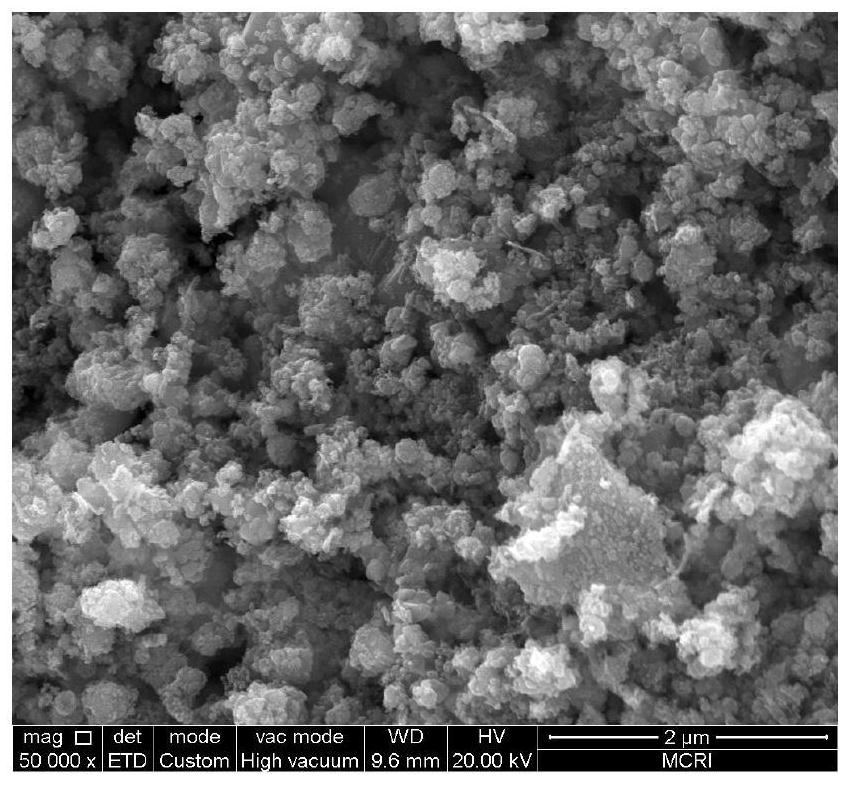

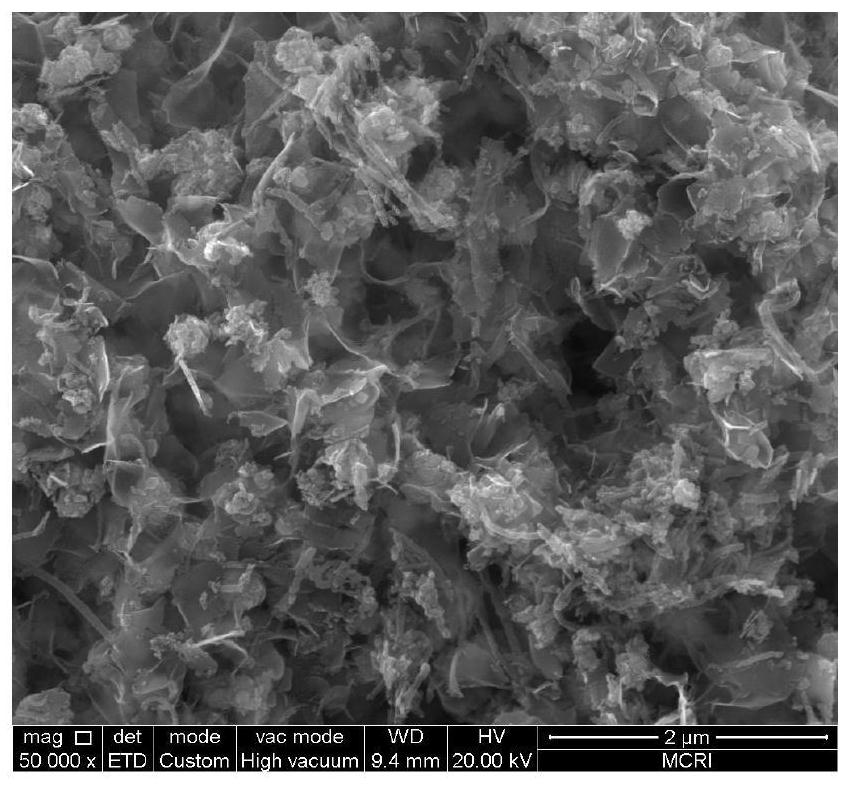

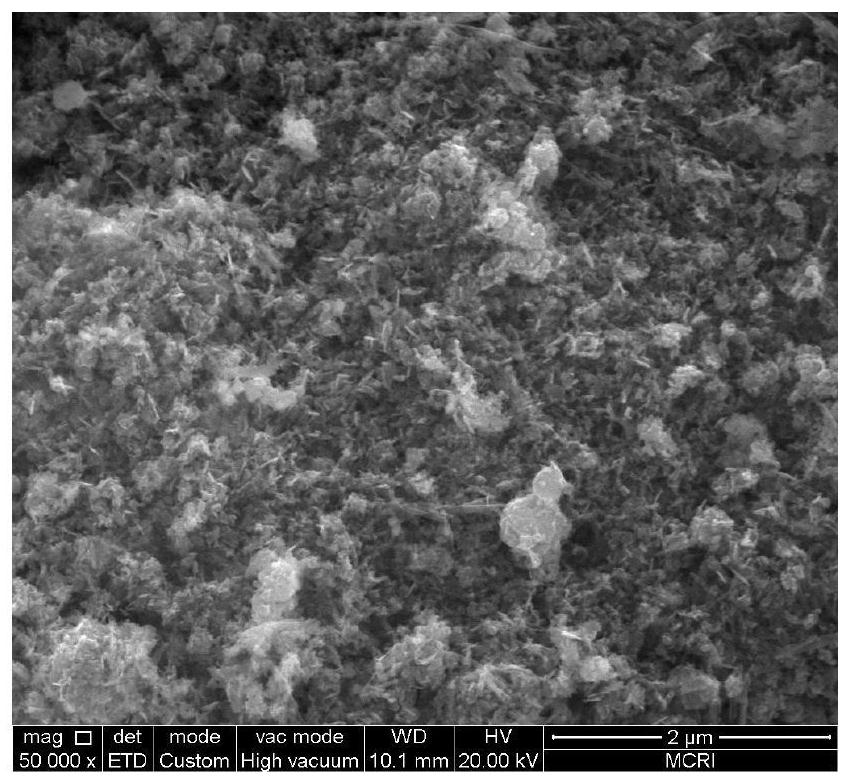

Image

Examples

Embodiment 1

[0041] A kind of preparation method of the copper-cobalt-based catalyst that is used for the synthesis gas system low-carbon alcohol of the present invention is specifically implemented according to the following steps:

[0042] Step 1, heat the carbon nanotubes in concentrated nitric acid to 80°C, reflux for 5h, filter and wash until neutral, dry in an oven at 110°C for 10h overnight, then grind, and sieve with a 200-mesh sieve, Then vapor-coated on carbon paper, and dried naturally to obtain the cathode electrode material;

[0043] Among them, the steam coating process is as follows: Weigh 0.053g of phenolic resin and 0.064g of polyvinylidene fluoride, add them to 22ml of N,N-dimethylacetamide, carry out ultrasonic vibration in a water bath at 40°C for 20min, and then add 0.3g of After the treatment of carbon nanotubes, continue to ultrasonically vibrate for 10 minutes to obtain a mixed solution, and then use a titanium plate with a size of 12 × 12 cm to place it above a con...

Embodiment 2

[0054] A kind of preparation method of the copper-cobalt-based catalyst that is used for the synthesis gas system low-carbon alcohol of the present invention is specifically implemented according to the following steps:

[0055] Step 1 is identical with embodiment 1;

[0056] Step 2, add anhydrous copper sulfate, cobalt sulfate heptahydrate, sodium citrate and sodium sulfate in 1L of deionized water, stir well to obtain solution a, and then use sulfuric acid solution or sodium hydroxide solution to adjust the pH value of solution a to 4.5, after adjustment, place solution a in a constant temperature water bath at a temperature of 50°C to obtain an electrolyte;

[0057] Wherein, the concentration of the anhydrous copper sulfate in solution a is 5g / L, the concentration of cobalt sulfate heptahydrate is 40g / L, the concentration of sodium citrate is 50g / L and the concentration of sodium sulfate is 20g / L;

[0058] Step 3, place the cathode electrode material and anode electrode ma...

Embodiment 3

[0064] A kind of preparation method of the copper-cobalt-based catalyst that is used for the synthesis gas system low-carbon alcohol of the present invention is specifically implemented according to the following steps:

[0065] Step 1 is identical with embodiment 1;

[0066] Step 2, add anhydrous copper sulfate, cobalt sulfate heptahydrate, sodium citrate and sodium sulfate in 1L of deionized water, stir well to obtain solution a, and then use sulfuric acid solution or sodium hydroxide solution to adjust the pH value of solution a to 4.5, after adjustment, place solution a in a constant temperature water bath at a temperature of 50°C to obtain an electrolyte;

[0067] Wherein, the concentration of the anhydrous copper sulfate in solution a is 5g / L, the concentration of cobalt sulfate heptahydrate is 40g / L, the concentration of sodium citrate is 40g / L and the concentration of sodium sulfate is 20g / L;

[0068] Step 3, place the cathode electrode material and anode electrode ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com