A sn-doped β-ga 2 o 3 Preparation method of film solar-blind ultraviolet detector

An ultraviolet detector, -ga2o3 technology, applied in the field of ultraviolet detection, can solve the problems of high cost of membrane, toxic and harmful reaction source, slow response time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

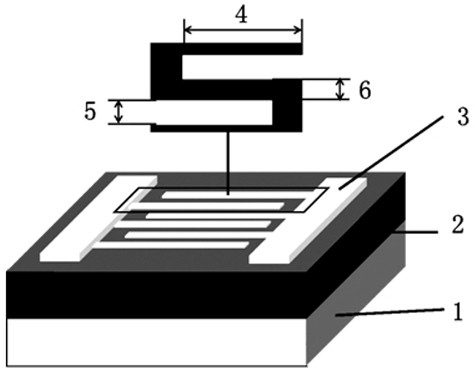

[0019] The invention provides a Sn doped β-Ga 2 o 3 The film preparation method is characterized in that: the preparation method is carried out according to the following steps:

[0020] (1) Ga 2 o 3 Powder, SnO 2 The powder and the carbon powder are mixed in a mass ratio of 0.05-1:0.05-1:1 and fully ground to obtain a solid mixed powder;

[0021] (2) Use the mixed powder as the reaction source, the distance between the reaction source and the substrate is 0.5cm-20cm, put it in a high-temperature tube furnace, the temperature of the reaction source is 900°C-1200°C, use chemical vapor deposition method, use oxygen as Oxygen source, inert gas as carrier gas, the flow ratio of oxygen and inert gas is 0.5-10mL / min: 0-100mL / min, the substrate temperature is 1000°C-1300°C, and the growth pressure is 1 Pa-10 5 Pa, the deposition time is 5 min-60 min, and Sn doped β-Ga is obtained on the substrate 2 o 3 membrane;

[0022] (3) In the Sn-doped β-Ga 2 o 3 A planar metal interd...

Embodiment 1

[0036] Ga 2 o 3 Powder, SnO 2 Powder and carbon powder are mixed in proportion and fully ground to obtain solid mixed powder, Ga 2 o 3 Powder, SnO 2 The mass ratio of powder to carbon powder mixed powder is 1:0.2:1; the mixed powder is placed in a ceramic boat as a reaction source, the ceramic boat is placed in a high-temperature tube furnace, and the substrate is placed in a high-temperature tube furnace. In the downwind direction of the ceramic boat, the downwind direction is the airflow direction of the mixed gas of oxygen and argon, and the distance between the reaction source and the substrate is 15cm; the ratio of oxygen and argon is 7mL / min: 30 mL / min; the substrate is sapphire; Heat the ceramic boat and the substrate to the preset temperature, the temperature of the reaction source is 1170 °C, and the temperature of the substrate is 1250 °C; use a vacuum pump to draw a vacuum to the system to achieve a growth vacuum, and the pressure is 30 Pa; Sn-doped β-Ga grown ...

Embodiment 2

[0039] Ga 2 o 3 Powder, SnO 2 Powder and carbon powder are mixed in proportion and fully ground to obtain solid mixed powder, Ga 2 o 3 Powder, SnO 2 The mass ratio of powder to carbon powder mixed powder is 1:0.5:1; the mixed powder is placed in a ceramic boat as a reaction source, the ceramic boat is placed in a high-temperature tube furnace, and the substrate is placed in a high-temperature tube furnace. In the downwind direction of the ceramic boat, the downwind direction is the airflow direction of the mixed gas of oxygen and argon, and the distance between the reaction source and the substrate is 15cm; the ratio of oxygen and argon is 7mL / min: 30 mL / min; the substrate is sapphire; Heat the ceramic boat and the substrate to the preset temperature, the temperature of the reaction source is 1170 °C, and the temperature of the substrate is 1250 °C; use a vacuum pump to draw a vacuum to the system to achieve a growth vacuum, and the pressure is 30 Pa; Sn-doped β-Ga grown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com