LiPF6 production process and LiPF6 production system

A production process and product technology, applied in the direction of alkali metal compounds, inorganic chemistry, lithium compounds, etc., can solve the problems of undisclosed lithium hexafluorophosphate product purity and high cost of lithium hexafluorophosphate products, and achieve reduced gas separation and purification costs, low production costs, high The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

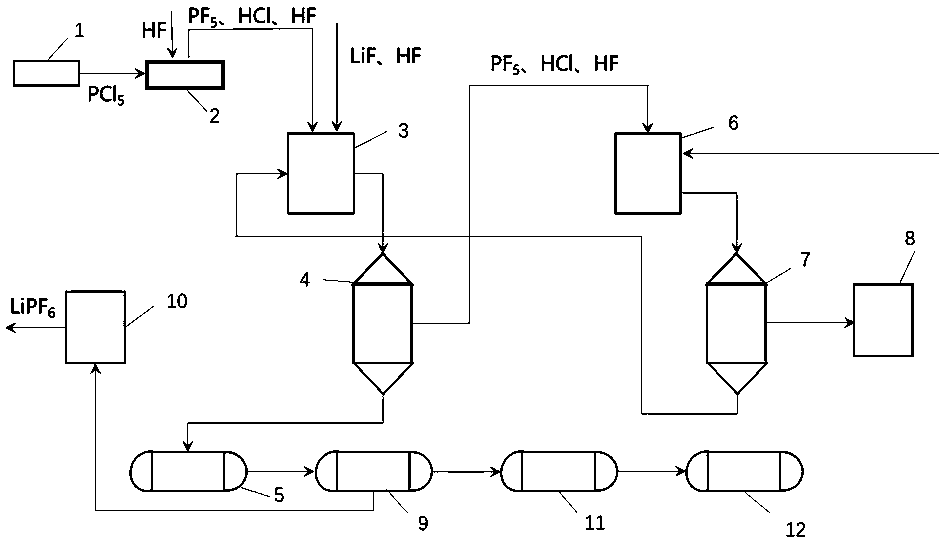

[0055] The phosphorus pentachloride is transported to the phosphorus pentafluoride generator 2 with cooling jacket and stored in hydrogen fluoride through the solid conveyor 1 with a metering device. The temperature is controlled at about 0°C, and the phosphorus pentachloride is mixed with Hydrogen fluoride reacts to produce phosphorus pentafluoride and hydrogen chloride. The mixed gas of phosphorus pentafluoride, hydrogen chloride and entrained hydrogen fluoride gas is passed into the first microchannel reactor 3 to form the first feed stream. Add hydrogen fluoride into the dissolution tank with cooling jacket and agitator, and add lithium fluoride into the dissolution tank with a solid feeding device while cooling, control the dissolution temperature to be about 0°C, and the mass fraction of lithium fluoride to be 2wt% . The hydrogen fluoride solution dissolved in lithium fluoride is transported into the first microchannel reactor 3 by a pump to form the second feed stream....

Embodiment 2

[0058] The difference between embodiment 2 and embodiment 1 production process is: the reaction temperature of the first microchannel reactor is 5 ℃, and the residence time is 10 seconds, and the reaction temperature of the second microchannel reactor is 8 ℃, and the residence time is 10 seconds .

[0059] After testing, the purity of the generated lithium hexafluorophosphate crystals is 99.994%, the yield is 99.8%, the particle size of crystal particles above 85% (wt) is 0.2-0.3mm, and the particle size of crystal particles above 93% (wt) is 0.18-0.35 mm.

Embodiment 3

[0061]The difference of embodiment 3 and embodiment 2 production technology is: the mol ratio of phosphorus pentafluoride and lithium fluoride is 2.5:1 in the first microchannel reactor, phosphorus pentafluoride and fluoride in the second microchannel reactor The molar ratio of lithium is 1:1.1.

[0062] After testing, the purity of the generated lithium hexafluorophosphate crystals is 99.995%, the yield is 99.8%, the particle size of crystal particles above 85% (wt) is 0.2-0.3mm, and the particle size of crystal particles above 94% (wt) is 0.18-0.35mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com