Environmentally friendly adhesive for citric acid-based plywood with ultra-high solid content, preparation method and application thereof

An ultra-high solid content, plywood technology, applied in the directions of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problems of inability to develop plywood preparation, low solid content of adhesives, inconvenient use, etc. Achieve the effect of improving thermal curing rate and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

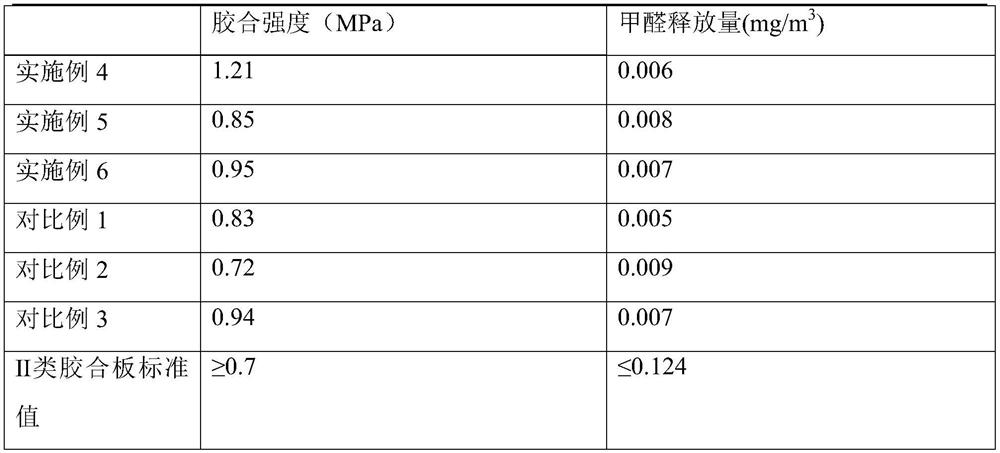

Examples

Embodiment 1

[0029] An ultra high solid content with green plywood adhesive, its composition ratio by weight of the following component composition:

[0030] 100 parts of citric acid;

[0031] 30 parts of sucrose;

[0032] 5 parts of cupric chloride;

[0033] 5 copulation of calcium oxide;

[0034] 10 parts of absolute ethanol;

[0035] 15 parts water;

[0036] Preparation of adhesive:

[0037] Parts by weight of the components weighed corresponding starting materials, the preparation of the adhesive, first mixed sucrose, copper chloride and water, the reaction was stirred at low speed 70 ℃ 1.5 hours and then citric acid was added to the reaction system at 90 deg.] C the reaction stirred at low speed for 3 hours after ethanol was added to the reaction system, high-speed stirring for 1 hour after warming device off at 80 ℃, after the temperature of the reaction system be cooled to room temperature, calcium oxide was added to the solution, stirred at low speed 0.5 Hour.

[0038] The prepared adh...

Embodiment 2

[0043] An ultra high solid content with green plywood adhesive, its composition ratio by weight of the following component composition:

[0044] 100 parts of citric acid;

[0045] 25 parts of sucrose;

[0046] 3 parts of copper chloride;

[0047] 2 parts of calcium oxide;

[0048] 15 parts of absolute ethanol;

[0049] 28 parts water;

[0050] Preparation of adhesive:

[0051] Parts by weight of the components weighed corresponding starting materials, the preparation of the adhesive, first mixed sucrose, copper chloride and water, the reaction was stirred at low speed 75 ℃ 1.2 hours and then citric acid was added to the reaction system at 95 deg.] C low reaction stirred for 2 hours, after addition of ethanol to the reaction system, high-speed stirring 0.8 hours the reaction was warmed closing means 85 ℃, after the temperature of the reaction system be cooled to room temperature, calcium oxide was added to the solution, stirred at low speed 0.4 Hour.

[0052] The prepared adhesive ...

Embodiment 3

[0057] An ultra high solid content with green plywood adhesive, its composition ratio by weight of the following component composition:

[0058] Plywood ultrahigh solid content with green adhesive having a composition comprising the following ingredients in weight percent:

[0059] 100 parts of citric acid;

[0060] 28 parts sugar;

[0061] 4 parts of copper chloride;

[0062] 3 parts of calcium oxide;

[0063] 13 parts of absolute ethanol;

[0064] 22 parts water;

[0065] Preparation of adhesive:

[0066] Parts by weight of the components weighed corresponding starting materials, the preparation of the adhesive, first mixed sucrose, copper chloride and water, the reaction was stirred at low speed 80 ℃ 1 hour and then citric acid was added to the reaction system at 100 ℃ for low speed for 1 hour, after addition of ethanol to the reaction system, a high speed stirring for 0.5 hours the reaction was warmed closing means 90 ℃, after the temperature of the reaction system be cooled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com