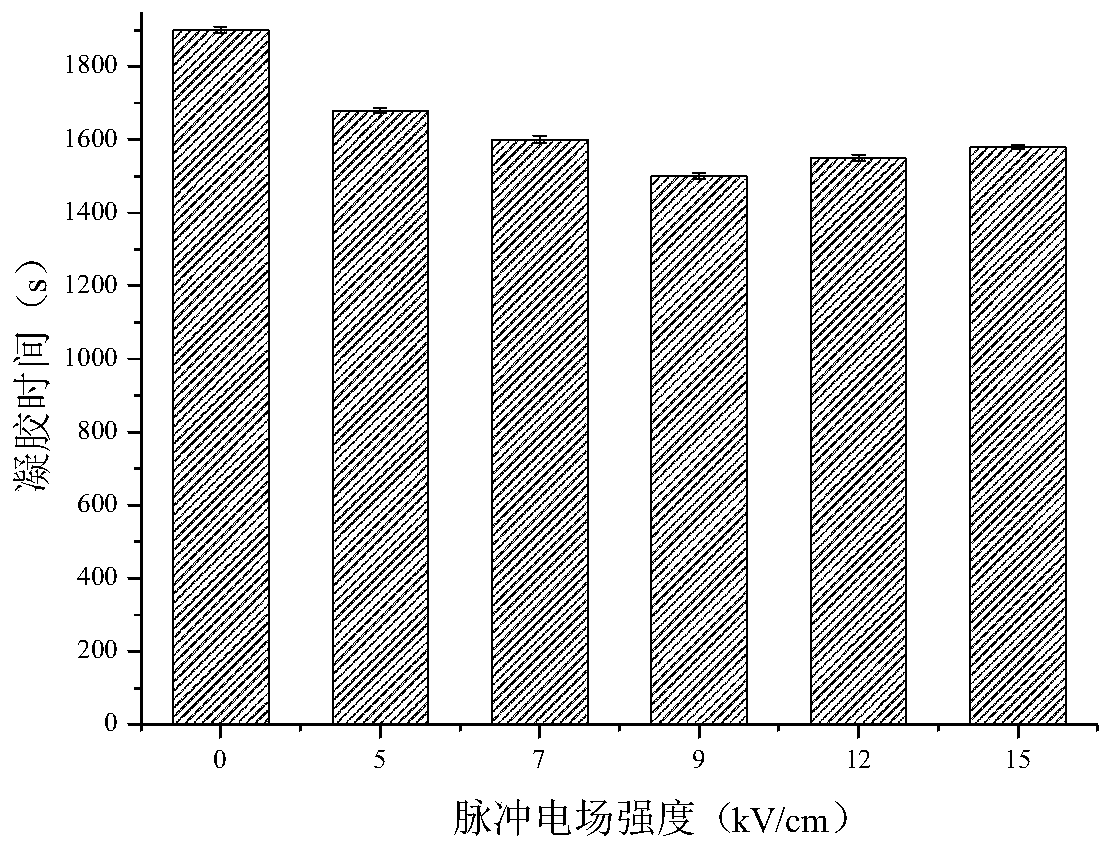

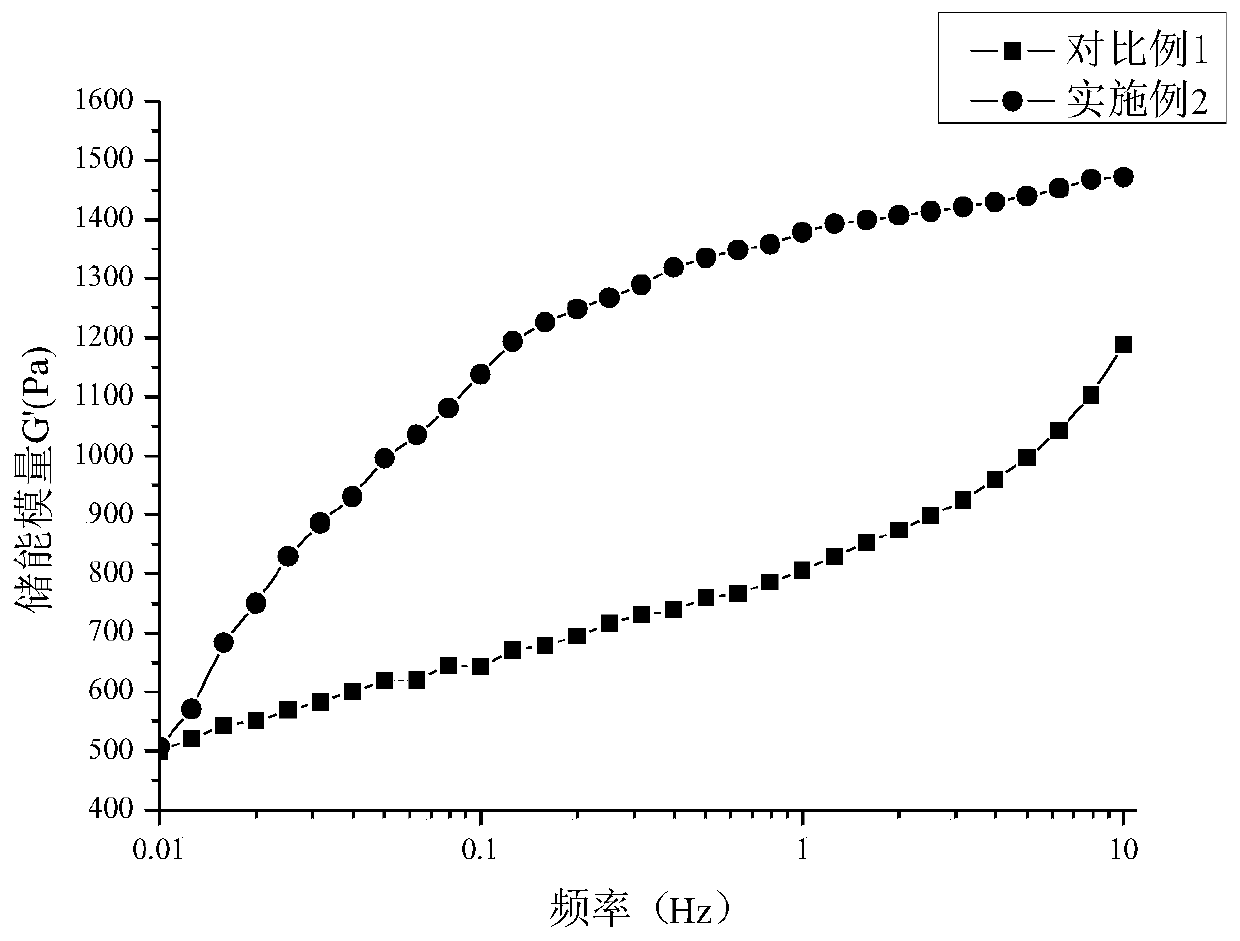

Emulsion gel embedding fat-soluble vitamins and production method based on pulsed electric field

A fat-soluble vitamin and production method technology, applied in the field of food engineering, can solve the problems of poor emulsion gel stability, no emulsion gel involved, long reaction time, etc., and achieve rich starch content, uniform filling and denseness, and emulsification. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Dissolve starch octenyl succinate in water, heat in a boiling water bath, stir until completely gelatinized and dissolved, cool to room temperature, add soybean oil dissolved in lycopene to obtain a mixed emulsion; control the content of the mixed emulsion Fraction 5% starch octenyl succinate, 0.1% lycopene and 10% soybean oil, use a high-speed disperser (IKA T25 high-speed disperser, Shanghai Shupei Experimental Equipment Co., Ltd.) to prepare a coarse emulsion, shear The rotating speed is 15000r / min, and the shearing time is 2min. Then pour into a high-pressure homogenizer (M-110EH micro-jet homogenizer, U.S. Microfluidics company) and homogenize three times under the condition of 80Mpa to obtain an emulsion, then add rice starch with a mass concentration of 8%, mix uniformly, and obtain a mixed solution .

[0046] Methylcellulose is dissolved in phosphate buffer (10mM, pH 7.0), and it is configured as a methylcellulose solution with a mass concentration of 0.5%, and...

Embodiment 2

[0050] Dissolve starch octenyl succinate in water, heat in a boiling water bath, stir until completely gelatinized and dissolved, cool to room temperature, add an appropriate amount of corn oil dissolved in β-carotene to obtain a mixed emulsion; control the mixed emulsion It contains 5% starch octenyl succinate, 0.02% β-carotene and 10% corn oil. A high-speed disperser (IKAT25 high-speed disperser, Shanghai Shupei Experimental Equipment Co., Ltd.) was used to prepare the coarse emulsion, with a shearing speed of 15000 r / min and a shearing time of 2 min. Then pour in the high-pressure homogenizer (M-110EH micro-jet homogenizer, U.S. Microfluidics company) after homogenizing three times under 80Mpa condition, obtain emulsion, then add the cornstarch of mass concentration 10%, mix well, get mixed solution .

[0051] Methylcellulose is dissolved in phosphate buffer (10mM, pH7.0), and it is configured as a methylcellulose solution with a mass concentration of 0.5%, and the prepare...

Embodiment 3

[0054] Dissolve starch octenyl succinate in water, heat in a boiling water bath, stir until completely gelatinized and dissolved, and cool to room temperature. A proper amount of peanut oil dissolved with tocopherol is added to obtain a mixed emulsion; the mixed emulsion is controlled to contain 10% starch octenyl succinate, 0.08% tocopherol and 20% peanut oil. A high-speed disperser (IKA T25 high-speed disperser, Shanghai Shupei Experimental Equipment Co., Ltd.) was used to prepare the coarse emulsion with a shear speed of 15000 r / min and a shear time of 2 min. Then pour in the high-pressure homogenizer (M-110EH micro-jet homogenizer, U.S. Microfluidics company) after homogenizing three times under 80Mpa condition, obtain emulsion, then add the potato starch of mass concentration 12%, mix homogeneously, get mixed solution .

[0055] Dissolve methylcellulose in phosphate buffer (10 mM, pH 7.0) to prepare a methylcellulose solution with a mass concentration of 3%. After mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Gel time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com