Two-dimensional I-doped BiOIO3/g-C3N4 composite catalyst and preparation method and application thereof

A composite catalyst, g-c3n4 technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of limiting the photocatalytic performance of pure catalysts, narrow visible light response range, and low specific surface area. The effect of low cost of raw materials, promotion of photocatalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Two-dimensional g-C 3 N 4 Preparation of nanosheets: First, add 10 g of urea into an aluminum crucible with a lid, put it into a muffle furnace, cover it, and calcinate at 550 °C for 4 h, with a heating rate of 2.5 °C min -1 (room temperature to 550 °C), after the muffle furnace was cooled to room temperature, a yellow solid was obtained; then the obtained yellow solid was spread in a rectangular crucible, and then calcined at 500 °C for 2 h, the heating rate was 5 °C min -1 (room temperature to 500°C), the light yellow product was collected, that is, the two-dimensional g-C 3 N 4 Nanosheets.

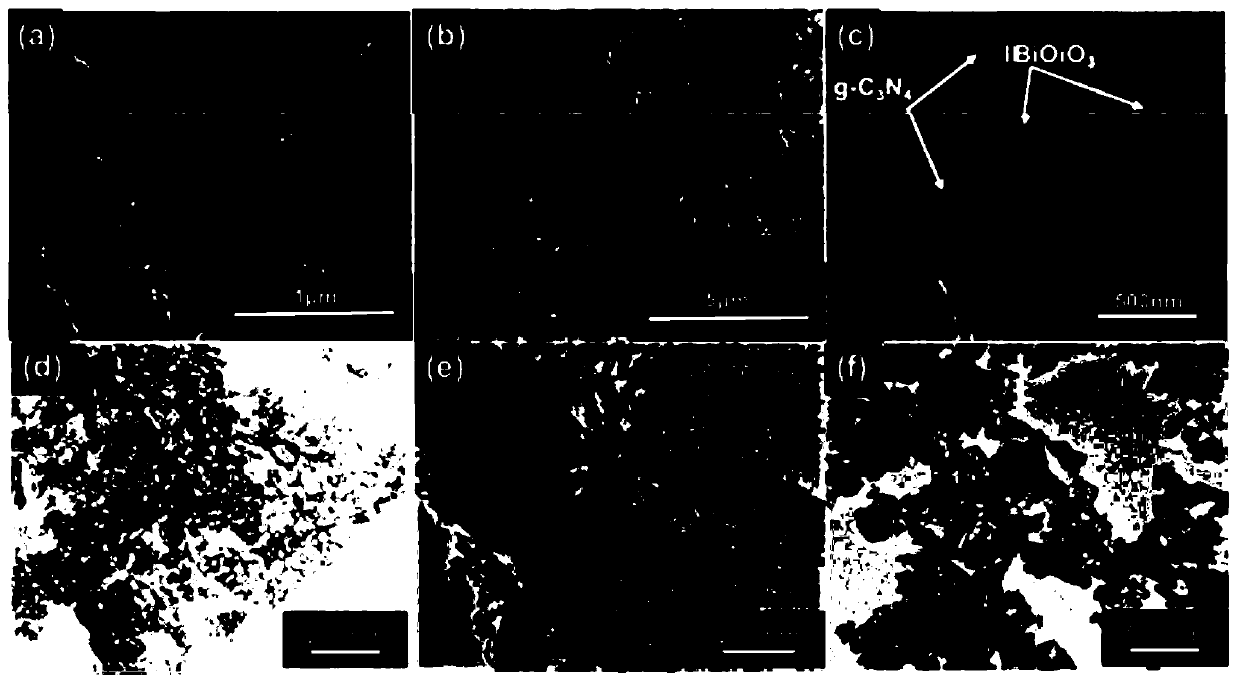

[0046] In order to observe the morphology of the material, the products prepared in this embodiment were characterized by scanning electron microscope and transmission electron microscope, with figure 1 is the two-dimensional g-C prepared in this example 3 N 4 SEM and TEM images of nanosheets, (a) and (d) are the g-C prepared in this example respectively 3 N 4 Nanosheets,...

Embodiment 2

[0048] First, 1.456 g Bi(NO 3 ) 3 ·5H 2 O and 0.5 g I 2 o 5 Dissolve in 30ml of deionized water, stir magnetically at room temperature for 15 minutes, then transfer to a 50ml reactor for hydrothermal reaction, the reaction temperature is 160°C, and the reaction time is 12 hours. When the system was naturally cooled to room temperature, the obtained white product was washed three times with water and ethanol respectively, and the product was collected by centrifugation, and then dried in an oven at 60 °C for 12 h to obtain BiOIO 3 Nanosheets, called BOI.

[0049] At room temperature, 0.5 g BiOIO was ultrasonically 3 Disperse evenly in 50 ml deionized water, then slowly drop 30 ml aqueous solution containing 0.1g KI into the above solution while continuing to stir, then keep stirring for 2 h, age for 1 h, centrifuge to collect the product, and the obtained light yellow The product was dried in an oven at 60 °C for 12 h to prepare I-doped BiOIO 3 Nanosheets, called IBOI. ...

Embodiment 3

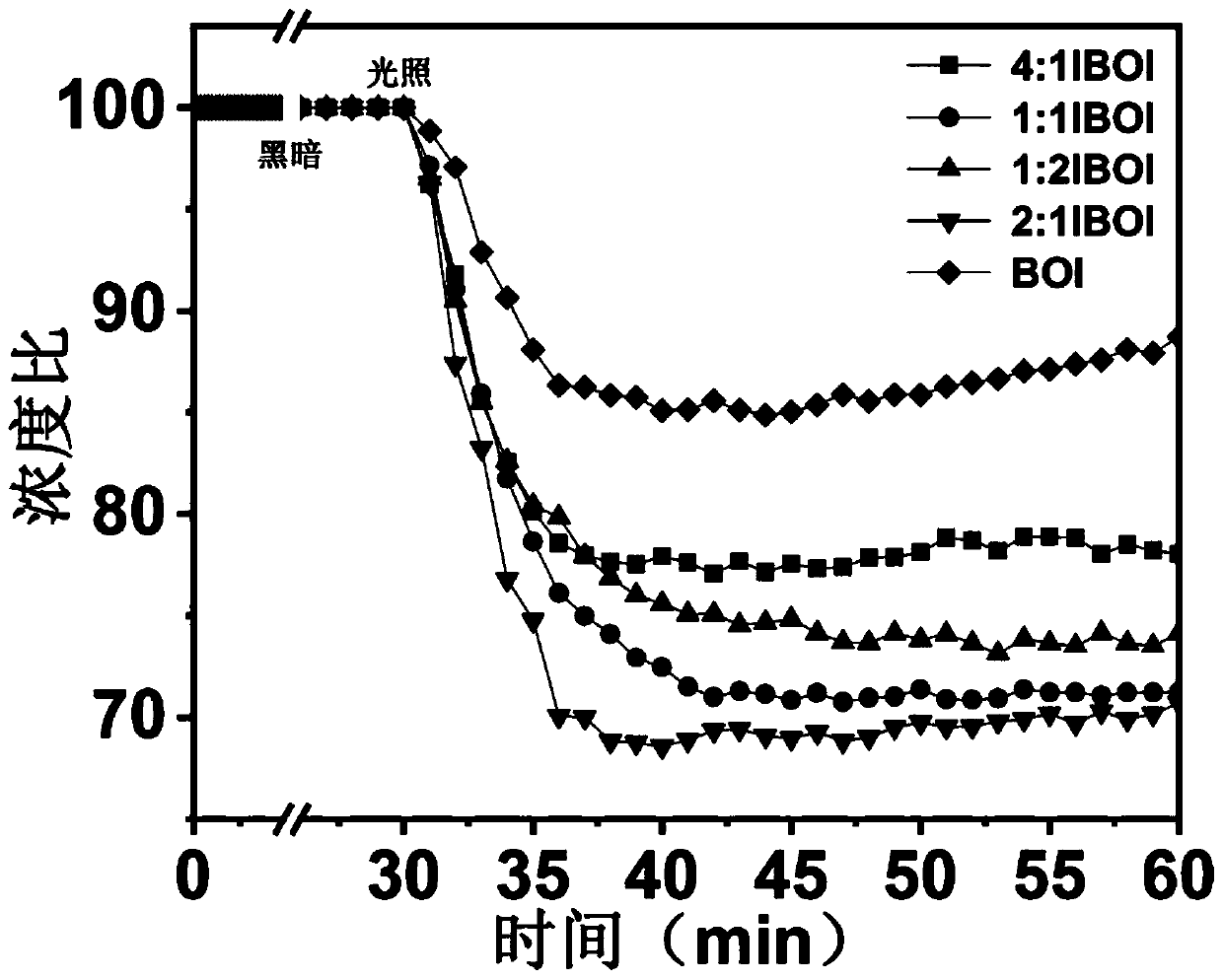

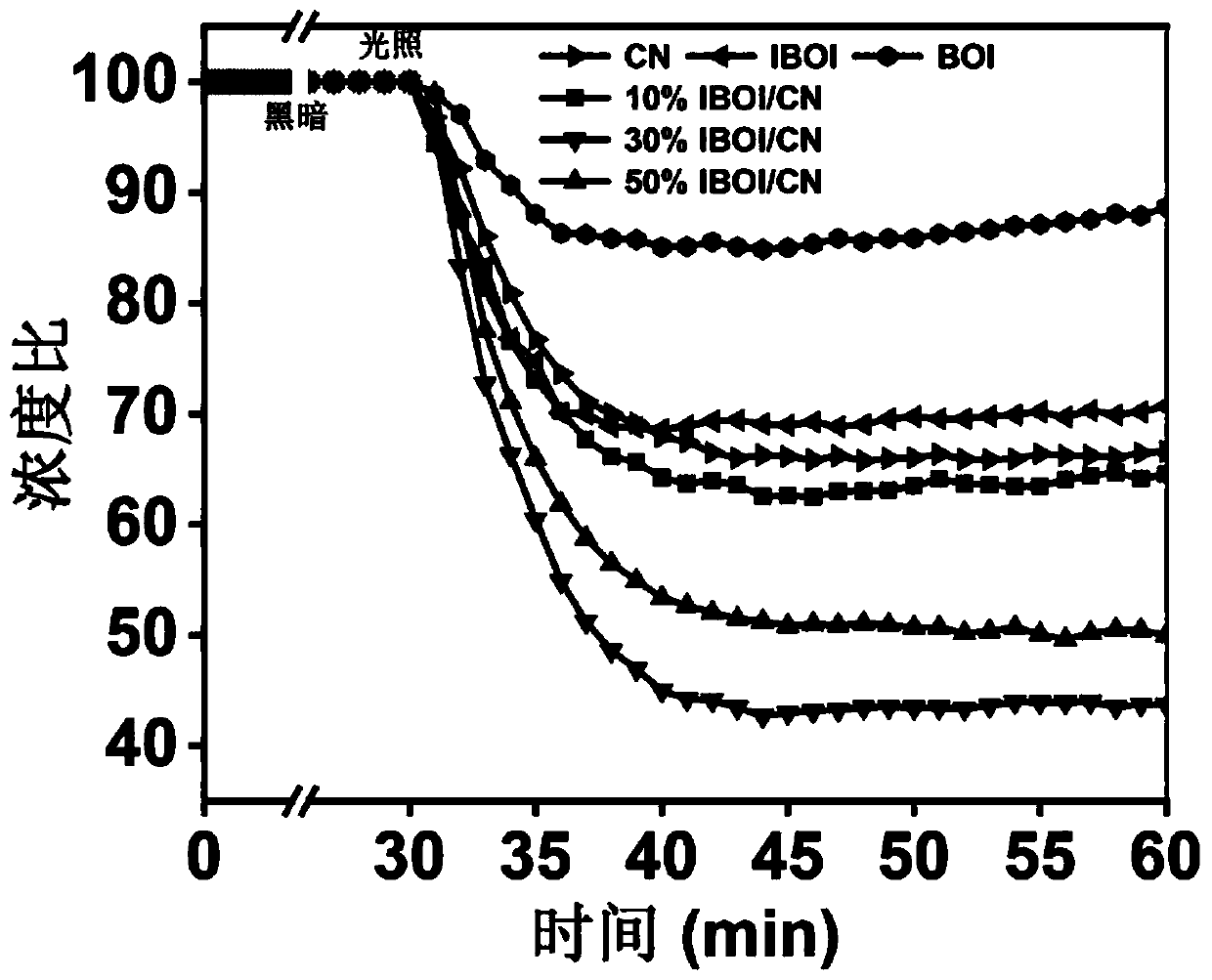

[0052] I-doped BiOIO 3 / g -C 3 N 4 Preparation of nanocomposites: First, 0.03 g 2:1I doped BiOIO 3 Ultrasonic dispersion in 80 ml ethanol for 30 minutes, then 0.07 g g-C 3 N 4 Add it into the solution, then sonicate the mixture for 1 h, stir for 1 h, then transfer it to a 100ml reaction kettle and react at 160°C for 6 h, then centrifuge, wash the light yellow product collected by centrifugation with water and ethanol several times, and store it at 60°C Drying in an oven for 12 h prepared I-doped BiOIO 3 / g -C 3 N 4 (I-doped BiOIO 3 / g -C 3 N 4 The composite catalyst, simply labeled as 30% IBOI / CN) nanocomposite, was used for the following SEM and TEM tests. According to the addition of I-doped BiOIO 3 10% IBOI / CN, 30% IBOI / CN, and 50% IBOI / CN were prepared with different proportions, among which, I doped BiOIO in 30% IBOI / CN 3 The dosage is 0.03g, g-C 3 N 4 is 0.07 g.

[0053] In order to observe the morphology of the materials after compounding, the products pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com