Light porous calcium carbonate material and preparation method thereof

A porous calcium carbonate, lightweight technology, applied in the field of materials, can solve the problems of achieving a stable state, low yield, and difficulty, and achieve the effect of improving freeze-thaw resistance and temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

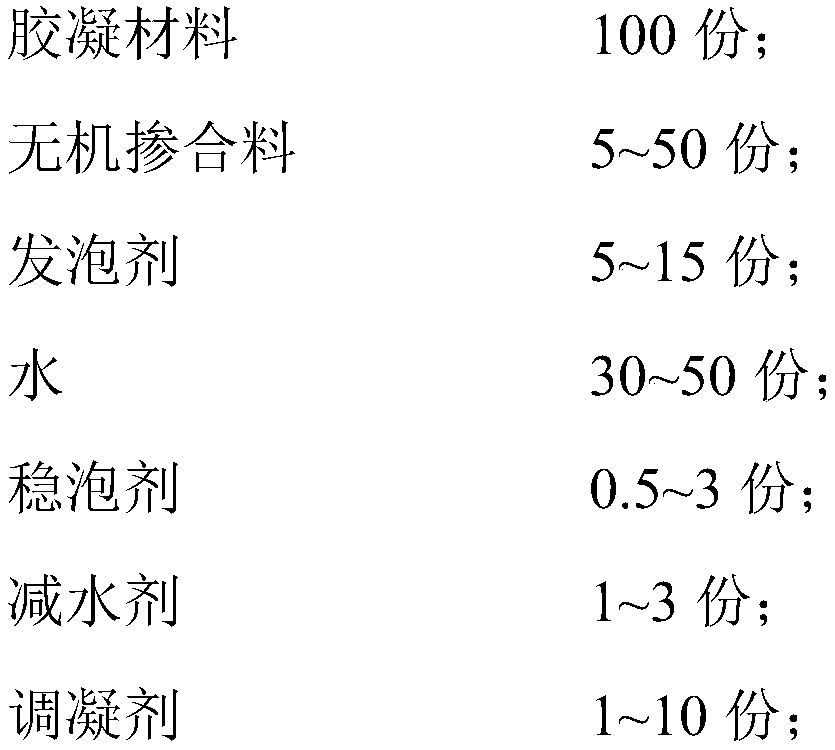

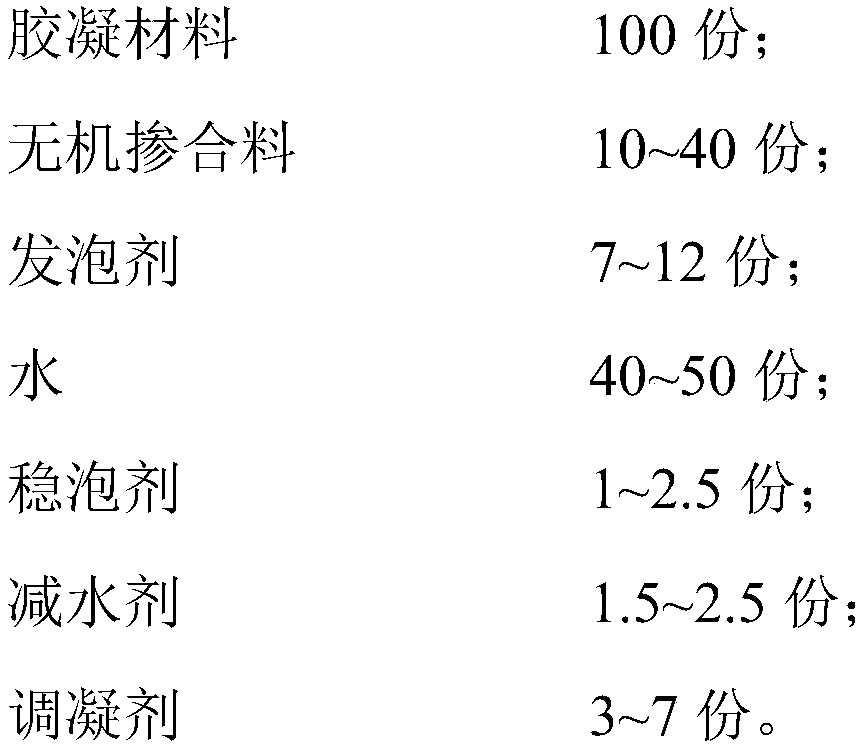

[0042] A kind of lightweight porous calcium carbonate foam material, each raw material is counted as: 100 parts of Ca(OH) by mass percentage 2 Powder, 0.75 parts of polypropylene fiber, 10 parts of silica fume, 7 parts of foaming agent (35% hydrogen peroxide), 50 parts of water, 1 part of foam stabilizer (sodium lauryl sulfate), 1.5 parts of water reducing agent agent (polycarboxylate superplasticizer), 5 parts of waterproofing agent (calcium stearate), and 5 parts of coagulation regulator (Portland cement).

[0043] A kind of preparation method of above-mentioned light porous calcium carbonate foam material, comprises the following steps:

[0044] 1) Take each raw material according to the above raw material ratio;

[0045] 2) Put the powdery raw materials and fibers in the cement mortar mixing pot and stir slowly for 30s to make the solid raw materials mix evenly;

[0046]3) Add mixing water, waterproofing agent, foam stabilizer, etc. into the dry mixing powder, and stir r...

Embodiment 2

[0051] A kind of lightweight porous calcium carbonate foam material, each raw material is counted as: 100 parts of Ca(OH) by mass percentage 2 Powder, 0.75 parts of polypropylene fiber, 20 parts of calcium carbonate powder, 8 parts of silica fume, 10 parts of foaming agent (35% hydrogen peroxide), 45 parts of water, 5 parts of P.I42.5 cement, 1.5 parts Foam stabilizer (calcium stearate), 2 parts of water-reducing agent (melamine-based water-reducing agent), 5 parts of water-repellent (silicone-based water-repellent).

[0052] A kind of preparation method of above-mentioned light porous calcium carbonate foam material, comprises the following steps:

[0053] 1) Take each raw material according to the above raw material ratio;

[0054] 2) Put the powdery raw materials and fibers in the cement mortar mixing pot and stir slowly for 30s to make the solid raw materials mix evenly;

[0055] 3) Add mixing water, waterproofing agent, foam stabilizer, etc. into the dry mixing powder, ...

Embodiment 3

[0060] A kind of lightweight porous calcium carbonate foam material, each raw material is counted as: 100 parts of Ca(OH) by mass percentage 2 Powder, 0.75 parts of polypropylene fiber, 30 parts of calcium carbonate powder, 10 parts of silica fume, 10 parts of foaming agent (concentration is 35% hydrogen peroxide), 45 parts of water, 2.5 parts of foam stabilizer (hydroxymethyl cellulose Ether), 2.5 parts of water reducer (polycarboxylate water reducer), 5 parts of water repellent (calcium stearate), 7 parts of coagulation regulator (high alumina cement).

[0061] A kind of preparation method of above-mentioned light porous calcium carbonate foam material, comprises the following steps:

[0062] 7) taking each raw material according to the above raw material ratio;

[0063] 8) Put the powdery raw materials and fibers in the cement mortar mixing pot and stir slowly for 30s to make the solid raw materials mix evenly;

[0064] 9) Add mixing water, waterproofing agent, foam stabi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com