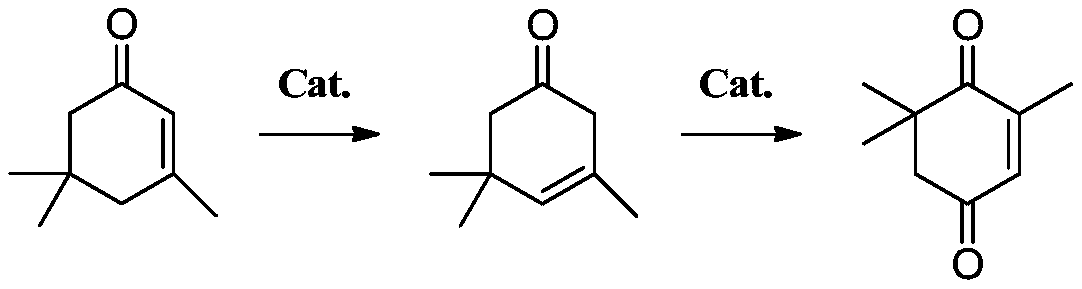

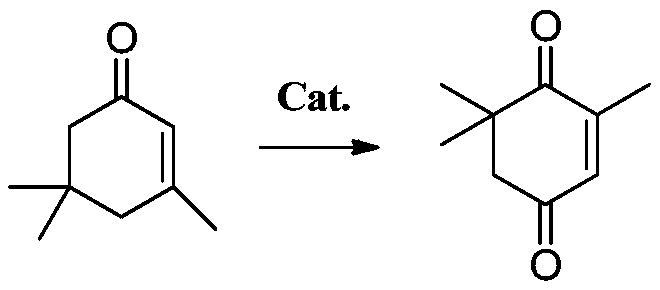

Method for catalytically synthesizing 4-ketoisophorone by adopting perovskite type composite oxide

A composite oxide, perovskite-type technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of low catalyst activity selectivity and difficult separation of catalysts The problems of mechanical application and unsatisfactory catalytic effect can achieve the effect of reducing energy consumption cost, easy separation and maintaining catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Catalyst preparation: according to the stoichiometric molar ratio La:K:Co:Mn=9:1:9:1, weigh a certain amount of lanthanum nitrate, potassium nitrate, cobalt nitrate and manganese nitrate, and then molar ratio metal cation: citric acid =1:1.1 Weigh an appropriate amount of citric acid, add it into distilled water, and use ultrasonic vibration to promote its dissolution, stir and evaporate to dryness in a water bath at 80°C to a sol state, place it in an oven to dry at 120°C, and then put The sample was calcined at 700°C for 3 hours to obtain the perovskite composite oxide catalyst La 0.9 K 0.1 co 0.9 mn 0.1 o 3+δ , denoted as catalyst A.

Embodiment 2

[0052] Preparation of the catalyst: according to the stoichiometric molar ratio La: Ca: Co: Fe = 1:1:1:1, weigh a certain amount of lanthanum nitrate, calcium nitrate, cobalt nitrate and ferric chloride, and then molar ratio metal cation: lemon Acid=1:1.1 Weigh an appropriate amount of citric acid, add it into distilled water, and use ultrasonic vibration to promote its dissolution, stir and evaporate to dryness in a water bath at 80°C to a sol state, place it in an oven to dry at 120°C, and then The sample was calcined at 700°C for 3 hours to obtain the perovskite composite oxide catalyst La 0.5 Ca 0.5 co 0.5 Fe 0.5 o 3+δ , denoted as catalyst B.

Embodiment 3

[0054] Catalyst preparation: weigh a certain amount of lanthanum acetate, strontium nitrate, cobalt chloride and copper sulfate according to the stoichiometric molar ratio La:Sr:Co:Cu=9:1:5:5, and then molar ratio metal cation: lemon Acid=1:1.1 Weigh an appropriate amount of citric acid, add it into distilled water, and use ultrasonic vibration to promote its dissolution, stir and evaporate to dryness in a water bath at 80°C to a sol state, place it in an oven to dry at 120°C, and then The sample was calcined at 700°C for 3 hours to obtain the perovskite composite oxide catalyst La 0.9 Sr 0.1 co 0.5 Cu 0.5 o 3+δ , denoted as catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com