Preparation method of composite flocculant and sewage treatment method

A composite flocculant and sewage technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of difficult promotion and use, high price, etc., and achieve good flocculation effect , Simple equipment, fast flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

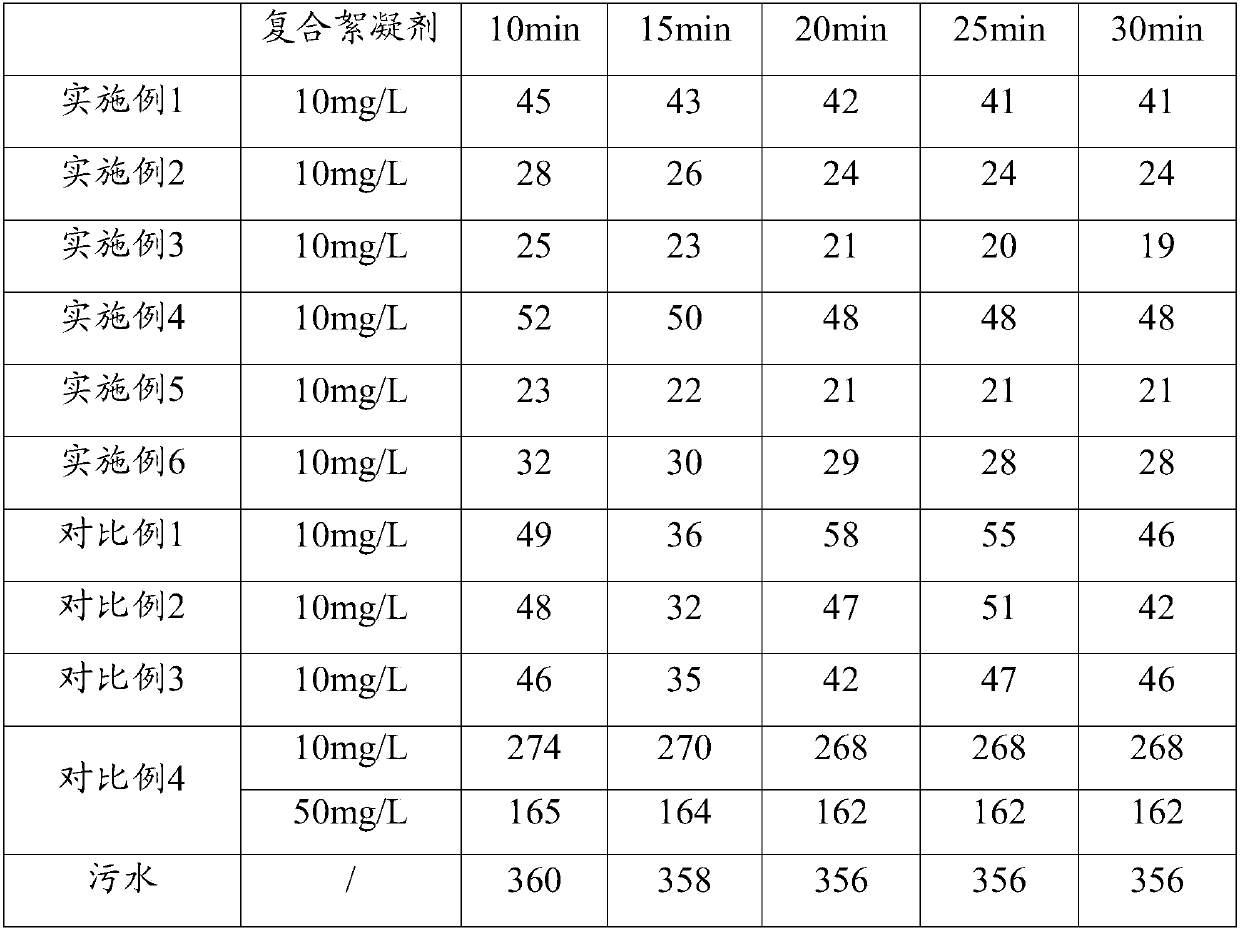

Embodiment 1

[0021] Take 3.00g of chitosan with 95% deacetylation and molecular weight of 5.0*104 and put it in a three-necked flask, add 12ml of 10wt% NaOH aqueous solution and 200ml of isoglycol, heat to 80-90°C under stirring, and start to add 20ml of mass 3-bromo-2-hydroxypropylammonium chloride aqueous solution with a fraction of 30%, stirring and controlling the dropping rate so that the temperature of the material is not higher than 100°C, and the material is discharged after a constant temperature reaction for 3 hours, and the mass fraction of the slurry is 10%. After adjusting the pH to 7.0 with hydrochloric acid, filter with suction, soak and wash the filter residue with 150ml of n-butanol and filter with suction twice, then soak and wash with 150ml of anhydrous methanol and filter with suction twice, and dry at 95°C to constant weight to obtain Chitosan quaternary ammonium salt.

[0022] Dissolve 2.5 g of the obtained modified chitosan quaternary ammonium salt in a beaker with 3...

Embodiment 2

[0024] Take 3.00g of chitosan with 95% deacetylation and molecular weight of 5.0*104 and put it in a three-necked flask, add 12ml of 10wt% NaOH aqueous solution and 200ml of isoglycol, heat to 80-90°C under stirring, and start to add 20ml of mass 3-bromo-2-hydroxypropylammonium chloride aqueous solution with a fraction of 30%, stirring and controlling the dropping rate so that the temperature of the material is not higher than 100°C, and the material is discharged after a constant temperature reaction for 3 hours, and the mass fraction of the slurry is 10%. After adjusting the pH to 7.0 with hydrochloric acid, filter with suction, soak and wash the filter residue with 150ml of n-butanol and filter with suction twice, then soak and wash with 150ml of anhydrous methanol and filter with suction twice, and dry at 95°C to constant weight to obtain Chitosan quaternary ammonium salt.

[0025] Dissolve 1.0 g of the prepared modified chitosan quaternary ammonium salt in a beaker with 3...

Embodiment 3

[0027] Take 3.00g of chitosan with 95% deacetylation and molecular weight of 5.0*104 and put it in a three-necked flask, add 10ml of 12wt% RbOH aqueous solution and 200ml of isoglycol, heat to 80-90°C under stirring, and start to add 15ml of 30% 3-bromo-2-hydroxypropyl ammonium chloride aqueous solution, stirring and controlling the addition rate, so that the temperature of the material is not higher than 100 ° C, and the material is discharged after 2.5 hours of constant temperature reaction, and the mass fraction of the slurry is 12% Sulfuric acid is adjusted to PH to 7.5 After suction filtration, the filter residue was soaked and washed with 150ml of n-butanol and suction-filtered twice, then soaked and washed with 150ml of absolute ethanol and suction-filtered twice, and dried at 90°C to constant weight to prepare chitosan quaternary ammonium Salt.

[0028] Dissolve 2.0 g of the prepared modified chitosan quaternary ammonium salt in a beaker with 300 mL of distilled water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com