Lithium-sulfur battery positive electrode material containing zif67-derived composite carbon material and preparation method, positive electrode sheet containing it, and lithium-sulfur battery

A technology for lithium-sulfur batteries and cathode materials, which is applied in lithium batteries, battery electrodes, and carbon preparation/purification, etc., can solve problems such as poor conductivity of elemental sulfur, and achieve the effects of accelerating the transformation reaction, increasing the ratio, and buffering volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a lithium-sulfur battery cathode active material, comprising the following steps:

[0042] (1)CoS 2 - Preparation of NC composite carbon materials:

[0043] Take 0.5mol Co(NO 3 ) 2 ·6H 2 O and 2mol 2-methylimidazole were respectively dissolved in 100ml of methanol, magnetically stirred for 30min until completely dissolved, then the methanol solution containing 2-methylimidazole was quickly poured into Co(NO 3 ) 2 ·6H 2 O methanol solution, washed several times with absolute ethanol, centrifuged, and vacuum-dried at 60°C for 12h to obtain the ZIF67 precursor;

[0044] The above-mentioned ZIF67 precursor was subjected to high-temperature sintering treatment under the protection of argon, and the temperature was raised to 800°C at a rate of 5°C / min and kept for 3 hours. After cooling to room temperature with the furnace, the product was collected and named Co-NC;

[0045] Modification of Co-NC with phosphorus: Co-NC is sprayed with aqueous so...

Embodiment 2

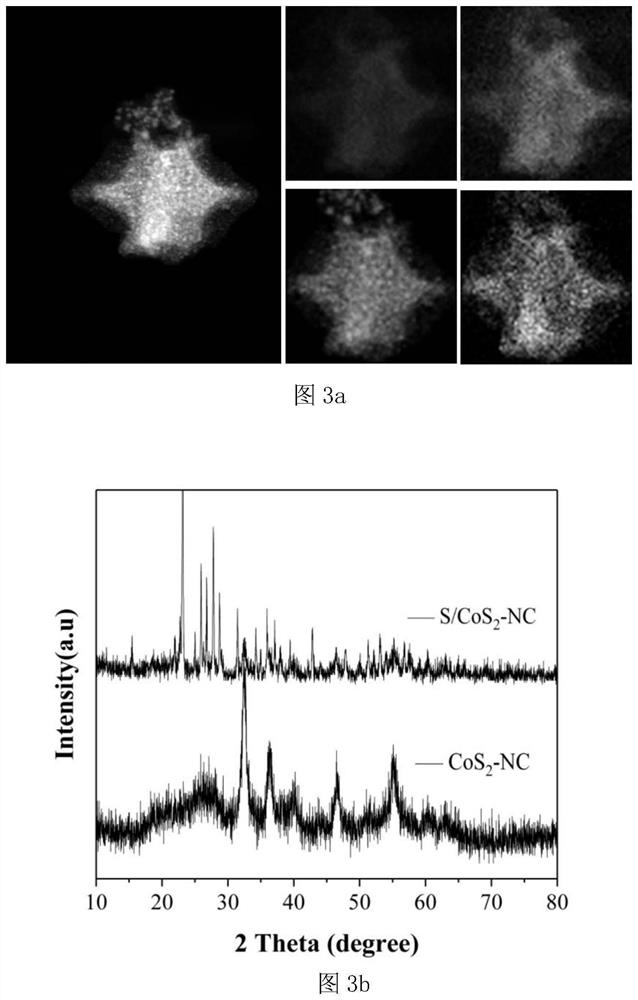

[0055] A lithium-sulfur battery, the lithium-sulfur battery cathode active material adopts the lithium-sulfur battery cathode active material described in Example 1 (refer to Figure 3 to Figure 4 ).

[0056] This embodiment provides a method for preparing a lithium-sulfur battery, comprising the following steps:

[0057] (1) Preparation of the positive electrode sheet: take the lithium sulfur positive electrode active material, superconducting carbon, and binder LA133 described in Example 1 by mass ratio 80:10:10 and place them in an agate ball mill jar, by mass ratio 1: 30 LA133, deionized water Weigh deionized water into the ball mill tank, high-energy ball mill at 400rpm for 30min, and then evenly coat the obtained slurry on the aluminum foil, the surface density is controlled to an average of 1.55mg / cm 2 , put the pole pieces obtained above in a vacuum drying oven, dry them in vacuum at 55°C for 24 hours, and cut them into small discs with a diameter of 15mm using a cutt...

experiment example

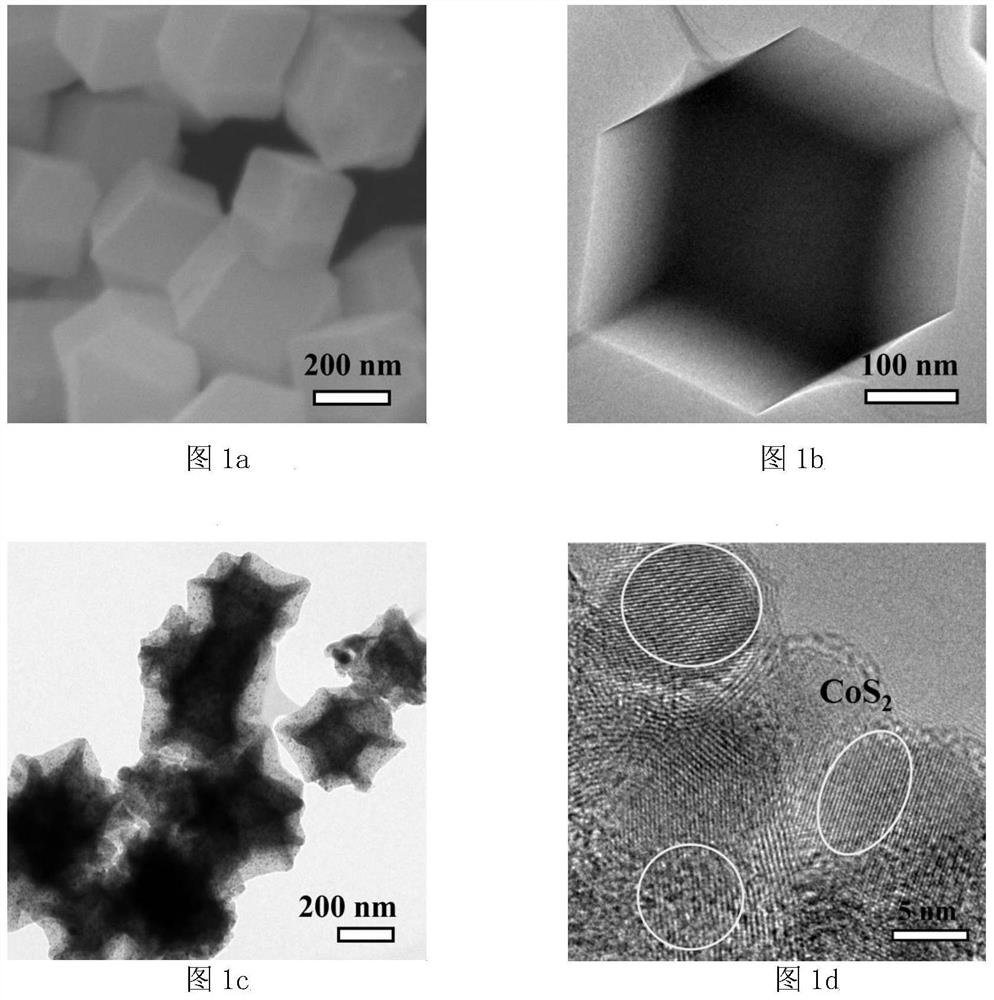

[0065] The composite carbon material and the composite lithium-sulfur cathode active material described in Example 1 and Comparative Example 1 were characterized as follows:

[0066] (1) X-ray diffraction (XRD): Utilize the diffraction phenomenon of X-rays in the material to analyze the crystalline state, crystal structure, crystal size, crystal composition, etc. of the material; the present invention is accordingly described in embodiment 2 and comparative example 2 Qualitative analysis of cathode active materials for lithium-sulfur batteries.

[0067] Test instrument: RIGAKU TTR-3 X-ray diffractometer.

[0068] Test conditions: radiation source is Cu target

[0069] Scanning range: 2θ=10-80°.

[0070] Scanning speed: 6° / min.

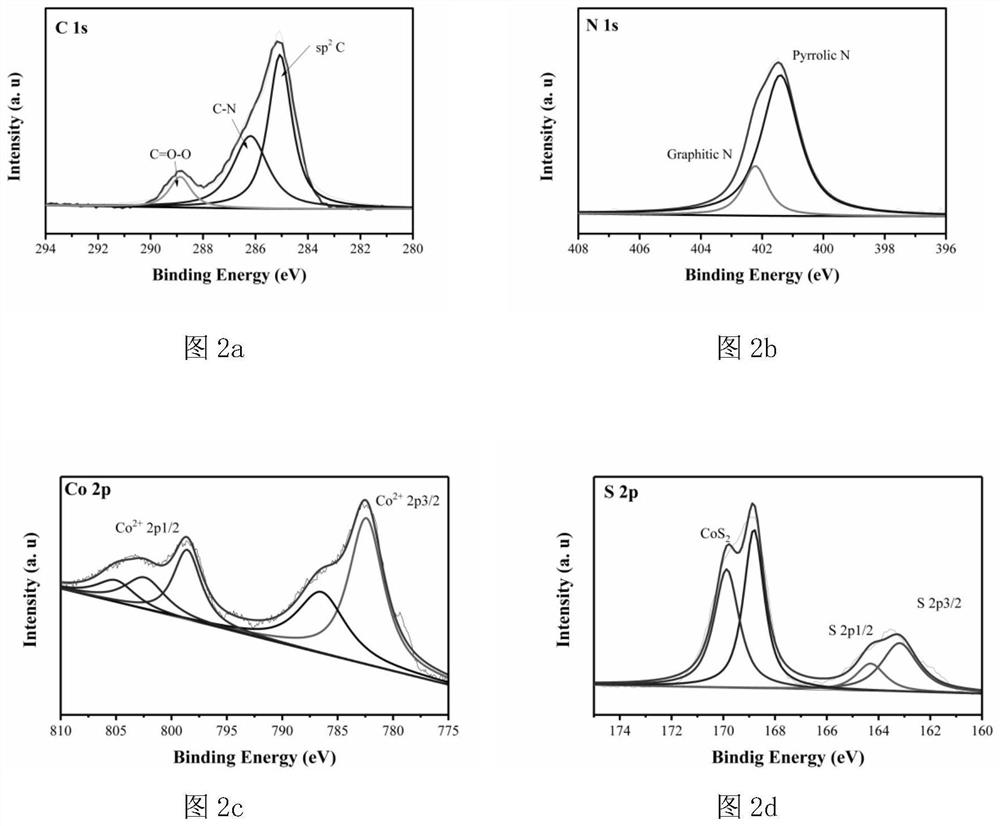

[0071] (2) X-ray Photoelectron Spectroscopy (XPS): Based on this, the present invention conducts qualitative analysis on the surface composition and element valence state of the composite carbon material described in Example 1.

[0072] Test inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com