High-strength low-odor two-component acrylate structural adhesive and preparation method thereof

An acrylate and acrylate technology, applied in the field of high-strength and low-odor two-component acrylate structural adhesive and its preparation, can solve the problems of reducing the adhesive strength of the colloid to plastic or metal, tackiness of the cured surface, etc. Adhesion, the effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

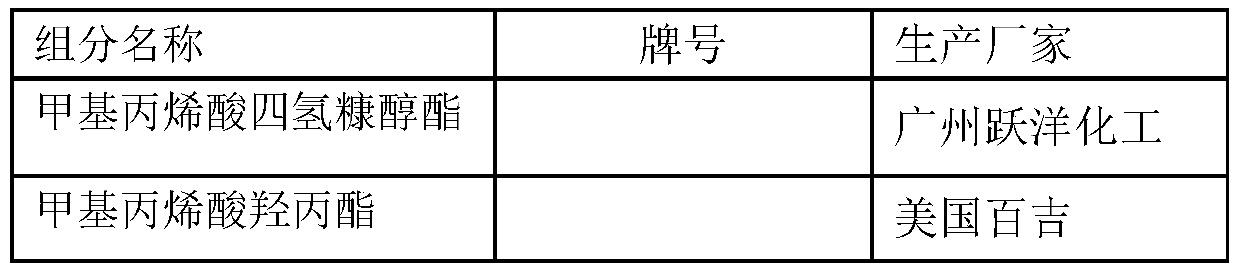

[0031] The source of each raw material is as follows:

[0032] component name Grade Manufacturer Hydroxyethyl methacrylate American bagels Hydroxypropyl Methacrylate American bagels 2-Phenoxyethyl methacrylate Changxing Chemical epoxy acrylate 2261 Changxing Chemical urethane acrylate 6112-100 Changxing Chemical maleic acid aladdin polyacrylic resin Dongguan Sanqi Chemical ABS resin GP-35 BASF KH-570 Jianghan Fine Chemicals hydroquinone Tianjin Oubokai Chemical Cumene Hydroperoxide Shandong Gaoming Chemical Tetramethylthiourea Jiangxi Galaxy New Materials fumed silica ML-150 Cabot

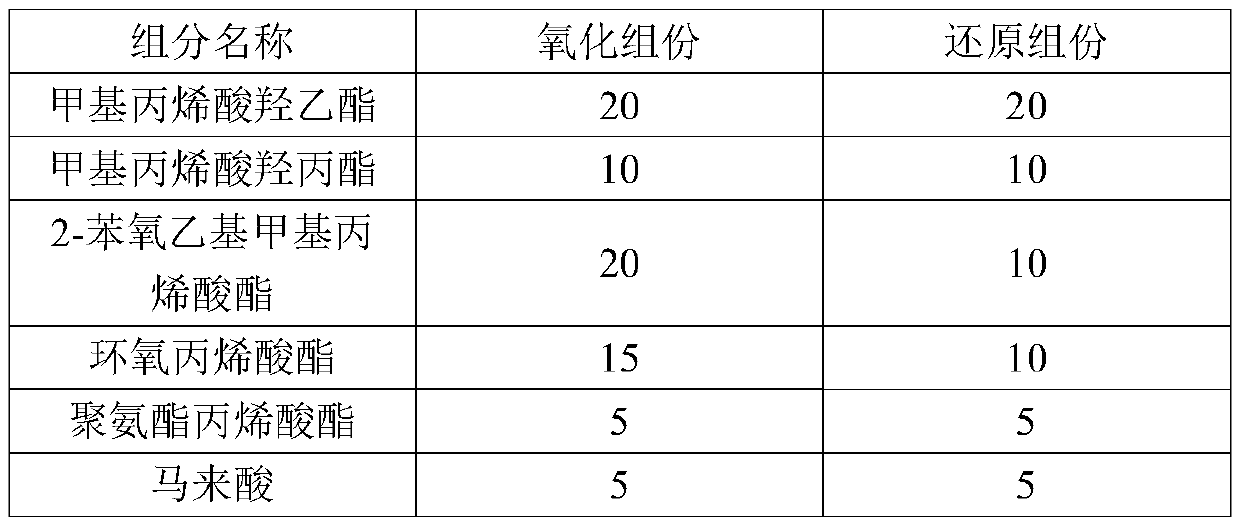

[0033] The proportioning (parts by weight) of oxidizing component and reducing component is as follows:

[0034]

[0035]

[0036] Preparation of Oxygenated Components

[0037] Taking materials in proportion, hydroxyethyl methacrylate, hydroxypropyl methacrylate,...

Embodiment 2

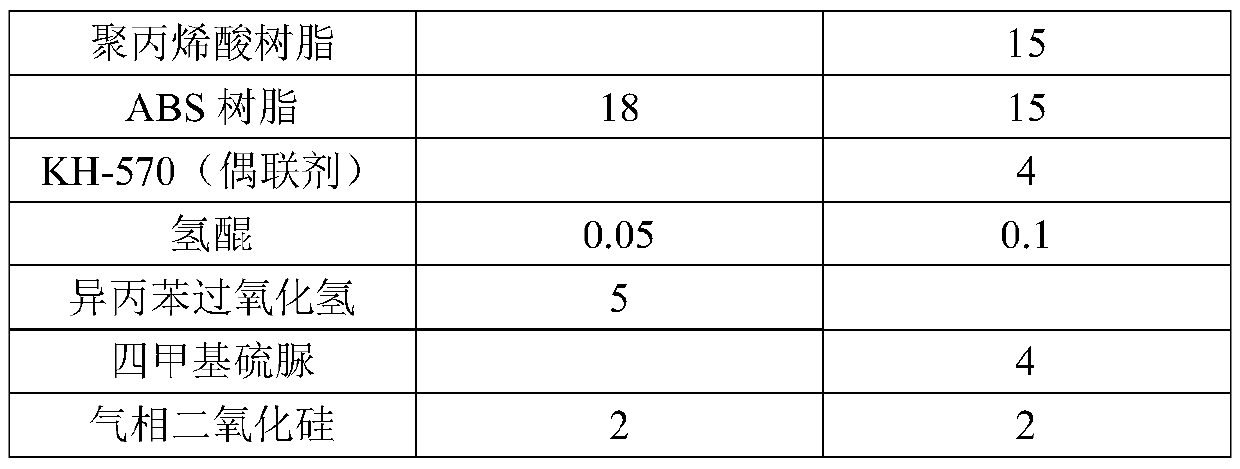

[0043] The source of each raw material is as follows:

[0044]

[0045]

[0046] Wherein, the preparation method of the toughening agent is: take bisphenol A epoxy resin, carboxyl-terminated nitrile rubber (CTBN), after weighing by mass ratio 1:1, add 1% triphenylphosphine in nitrogen atmosphere 140 It can be obtained by reacting at ℃ for 2h.

[0047] The ratio of oxidizing component and reducing component is as follows:

[0048]

[0049]Preparation of Oxygenated Components

[0050] Taking materials in proportion, tetrahydrofurfuryl methacrylate, hydroxypropyl methacrylate (acrylate monomer) and epoxy acrylate, ABS resin, polyurethane acrylate, polyacrylic resin, toughening agent (toughening agent) Resin) into the planetary mixer, high-speed stirring until the toughening resin is completely dissolved, then add cumene hydroperoxide (initiator), fumed silica (thixotropic agent), hydroquinone (stabilizer) in sequence, and finally pump Vacuum defoaming to obtain oxidiz...

Embodiment 3

[0056] The source of each raw material is as follows:

[0057] component name Grade Manufacturer Isobornyl Methacrylate Changxing Chemical Hydroxyethyl methacrylate American bagels epoxy acrylate L-6135 Dongguan Sanqi Chemical urethane acrylate L-9601 Dongguan Sanqi Chemical Methacrylate Chongqing Chuandong Chemical polyester resin L-8466 Dongguan Sanqi Chemical Toughener self made ABS resin GP-35 BASF Modified KH-560 Jianghan Fine Chemicals Benzoquinone German cherry tert-butyl peroxybenzoate aladdin 808HP (aniline condensate) Shanghai Guangyi Chemical hydrogenated castor oil Dandong Jinhai Fine Chemical Co., Ltd. Copper acetylacetonate aladdin

[0058] Wherein, the preparation method of toughening agent is: take bisphenol A epoxy resin, carboxyl-terminated nitrile rubber (CTBN), after weighing by mass ratio 1:1, add 1% triphenylphosphine i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com