Method for growing MOF by using bacteria as template to prepare multi-stage porous carbon material and application of multi-stage porous carbon material in energy storage devices

A porous carbon material, MOF technology, applied in the field of porous carbon materials, can solve the problems that a single noble metal catalyst cannot be used as a dual-function electrocatalyst at the same time, expensive and insufficient stability, restricting the wide application of noble metal catalysts, etc., to facilitate industrial fermentation, Good cycle performance, the effect of suppressing the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

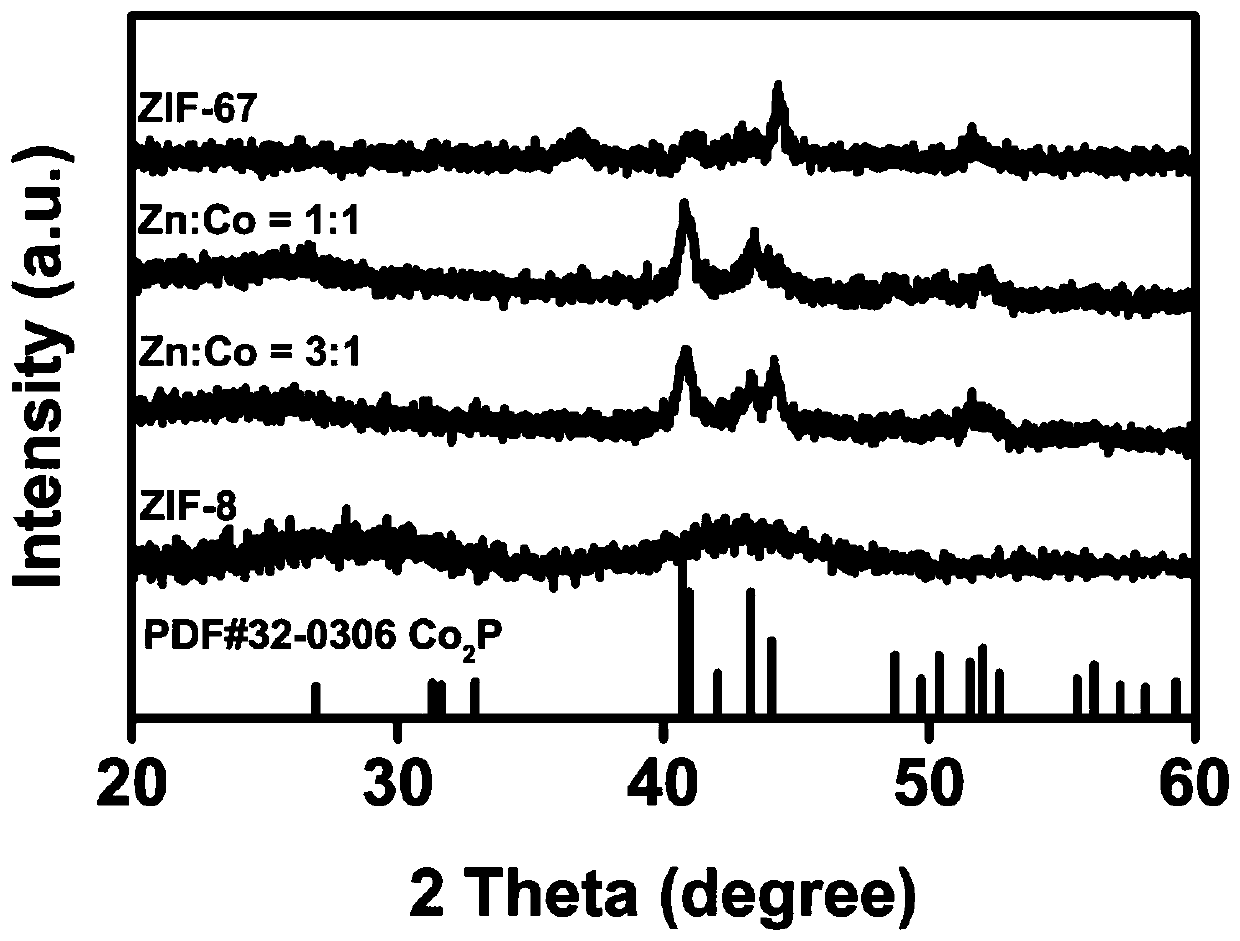

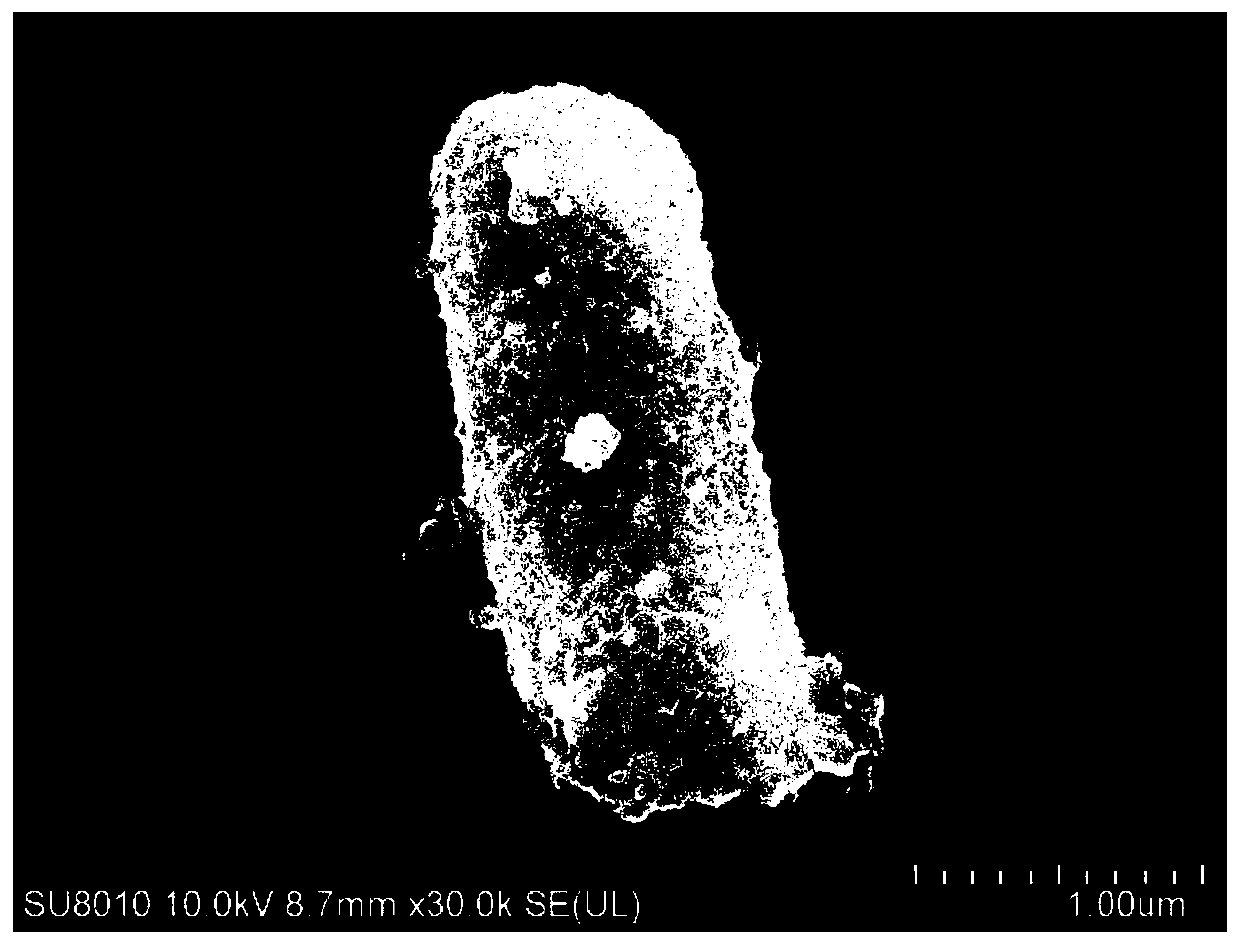

[0040] 0.2g Escherichia coli bacteria powder was uniformly dispersed into a bacterial suspension with 200mL methanol, then 2.4g dimethylimidazole and 1.2g zinc nitrate were added successively, stirred evenly, ultrasonicated for 30min, and left to grow ZIF-8 (a MOF materials). After 24 hours, centrifuge and wash with methanol several times to obtain a white precipitate, vacuum-dry it in a 60-degree oven for 12 hours, take it out, grind and weigh it, and then carbonize it at a heating rate of 5°C / min to 900°C under the protection of nitrogen or argon, and the carbonization time is 5 hours . After carbonization and cooling, it is ground to obtain a capsule-shaped multi-level porous active multifunctional carbon material.

[0041] The microscopic appearance of the multifunctional carbon material that embodiment 1 obtains is as follows figure 2 shown.

Embodiment 2

[0043] Disperse 0.2g of Escherichia coli powder with 200mL of methanol to form a bacterial suspension, then add 2.4g of dimethylimidazole, 0.9g of zinc nitrate and 0.3g of cobalt nitrate in sequence, stir well, then ultrasonicate for 30min, seal and let stand at room temperature to grow ZIF . After 24 hours, centrifuge and wash with methanol several times to obtain a light blue precipitate, dry it in a 60-degree oven for 12 hours in a vacuum, take it out, grind and weigh it, and then carbonize it at a heating rate of 5°C / min to 900°C under the protection of nitrogen or argon. Time 5h. After carbonization and cooling, it is ground to obtain a capsule-shaped multi-level porous active multifunctional carbon material.

[0044] The microscopic appearance of the multifunctional carbon material that embodiment 2 obtains is as follows image 3 shown.

Embodiment 3

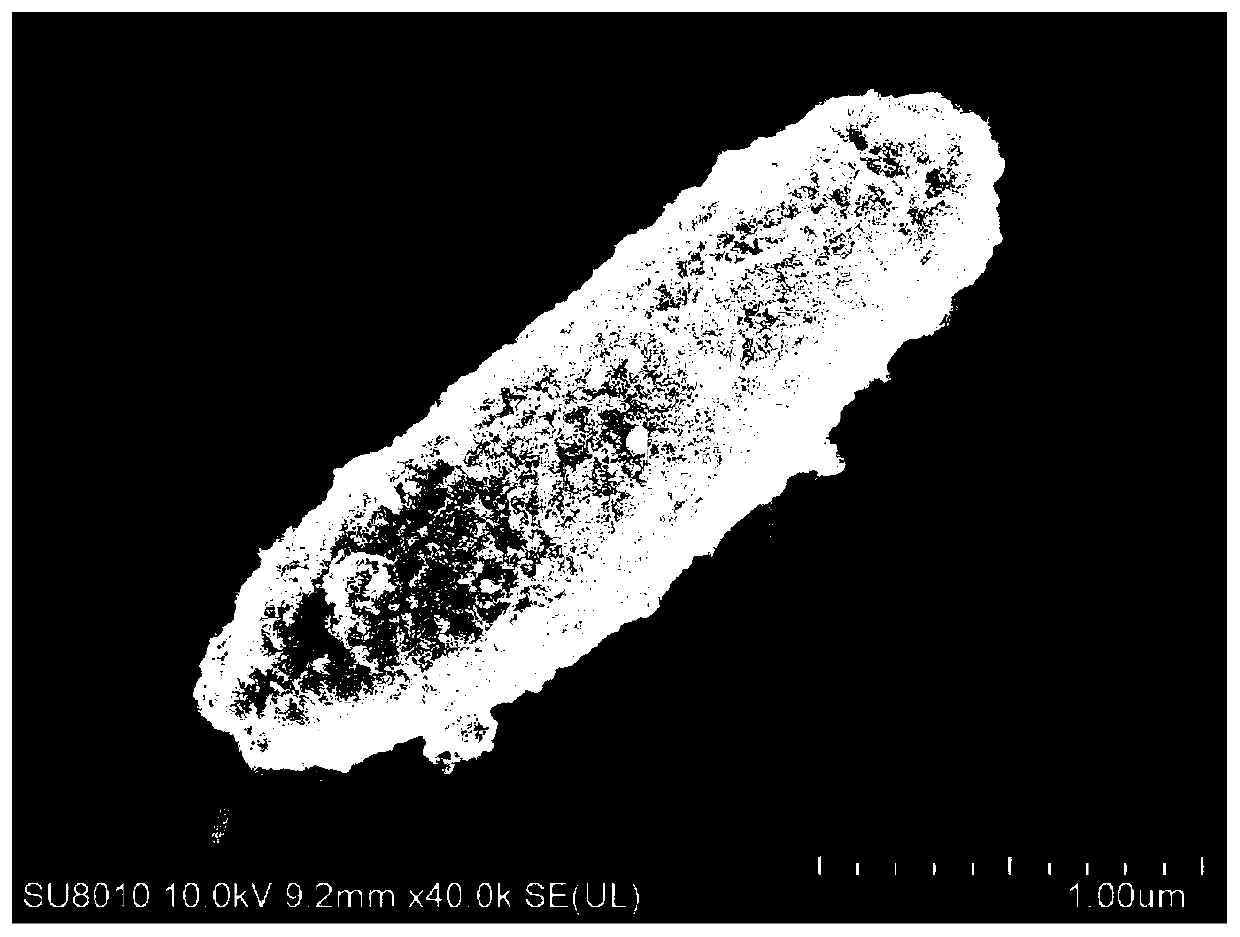

[0046] Disperse 0.2g of Escherichia coli powder with 200mL of methanol to form a bacterial suspension, then add 2.4g of dimethylimidazole, 0.6g of zinc nitrate and 0.6g of cobalt nitrate in sequence, stir well, and then ultrasonicate for 30min, seal and let stand at room temperature to grow ZIF . After 24 hours, it was centrifuged and washed with methanol several times to obtain a blue precipitate. It was vacuum-dried in a 60-degree oven for 12 hours, taken out, ground and weighed, and then carbonized at a heating rate of 5°C / min to 900°C under the protection of nitrogen or argon. The carbonization time 5h. After carbonization and cooling, it is ground to obtain a capsule-shaped multi-level porous active multifunctional carbon material.

[0047] Due to the increase of Co content, the product contains more Co nanoparticles and the product is enriched on the surface, the SEM image is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com