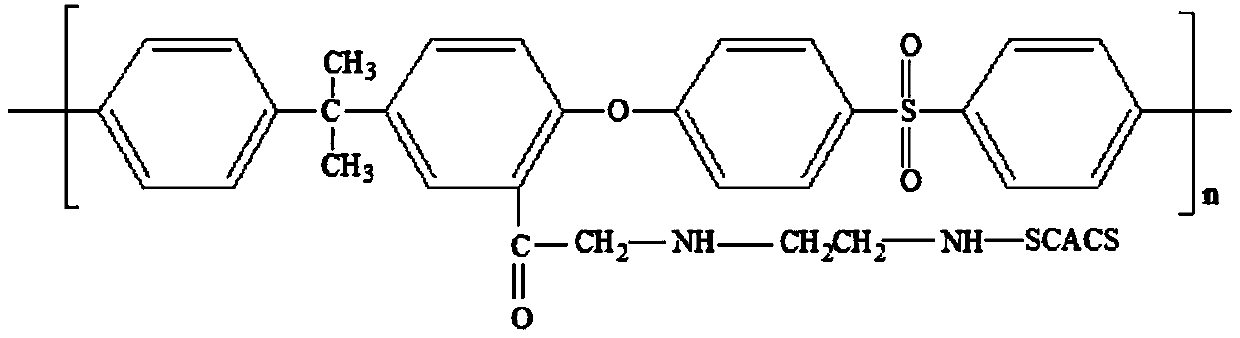

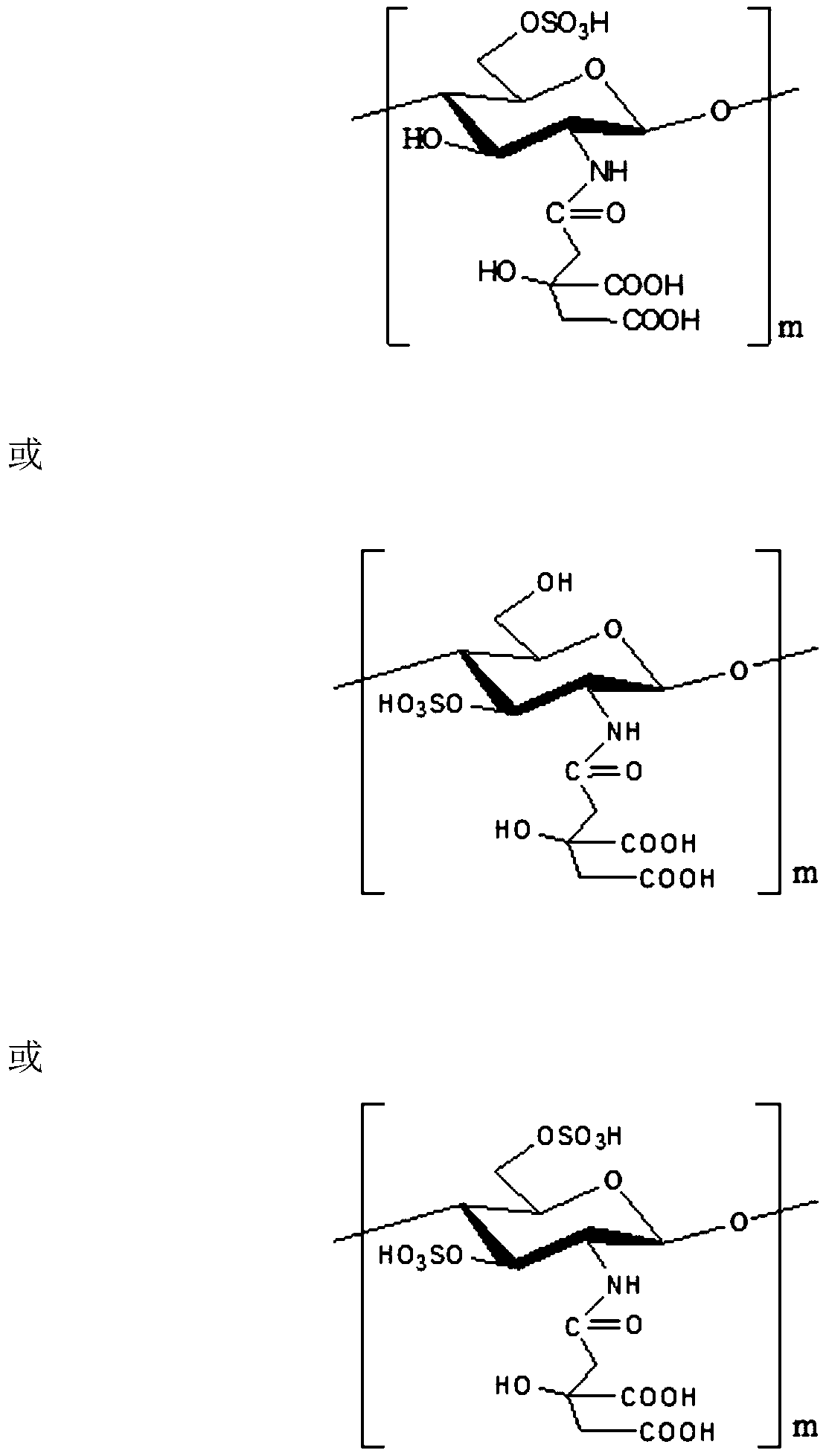

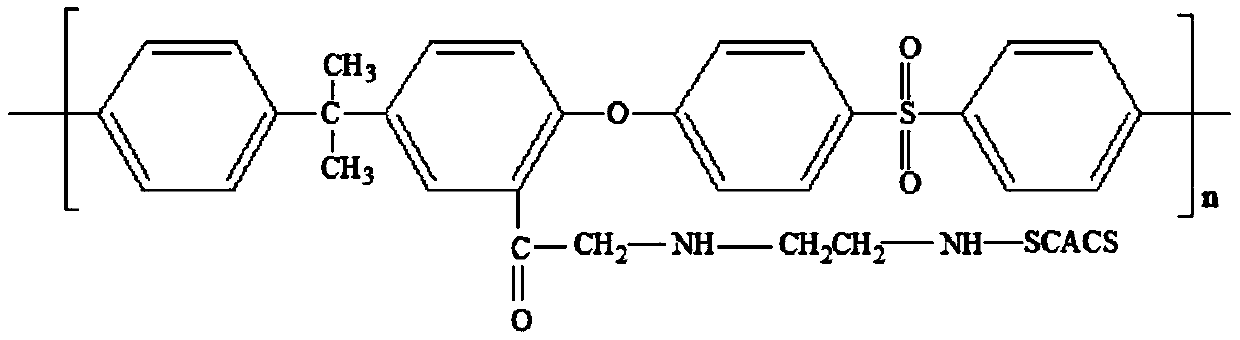

Sulfonated citric acid chitosan modified polysulfone hemodialysis film and preparation method thereof

A sulfonated citric acid, chitosan modification technology, applied in chemical instruments and methods, semi-permeable membrane separation, membranes, etc., can solve the problems of easy blood pollution, poor chemical stability, etc., and achieve good mechanical properties and biological Compatibility, excellent hydrophilicity, anti-protein adsorption and anticoagulant improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 18% of sulfonated citric acid chitosan modified polysulfone (mass fraction, the same below), 42% of N,N-dimethylformamide, and 40% of N,N-dimethylacetamide to the raw material tank , stirred at 25°C for 15 hours, after being fully dissolved, let it stand at room temperature for 18 hours to defoam, and a uniform film solution was obtained;

[0024] Open the nitrogen valve, maintain the pressure of the raw material tank at 0.20MPa, filter the modified polysulfone membrane liquid, and press it into the spinning head through the metering pump, control the flow rate of the membrane liquid to 1.15mL / min, and feed the core liquid at the same time, the flow rate is 1.09mL / min; the nascent film enters the coagulation bath and rinsing bath under the traction of the winding machine after passing through the air gap of 10cm, and then is wound on the drum; the winding speed is 45m / min, and the temperature of the coagulation bath is 28°C , the temperature of the rinsing bath was...

Embodiment 2

[0026] Add 20% (mass fraction, the same below) of sulfonated citric acid chitosan modified polysulfone and 80% N,N-dimethylacetamide into the raw material tank, stir at 25°C for 12 hours, and wait until fully dissolved , standing at room temperature for 18 hours to obtain a uniform membrane solution;

[0027] Open the nitrogen valve, maintain the pressure of the raw material tank at 0.10MPa, filter the modified polysulfone membrane liquid, and press it into the spinning head through the metering pump, control the flow rate of the membrane liquid to 1.03mL / min, and feed the core liquid at the same time, the flow rate is 1.01mL / min; the nascent film enters the coagulation bath and rinsing bath under the traction of the winding machine after passing through the air gap of 15cm, and then is wound on the drum; the winding speed is 36m / min, and the coagulation bath temperature is 20℃ , the temperature of the rinsing bath was 15°C; the obtained sulfonated citrate-chitosan modified p...

Embodiment 3

[0029] Add sulfonated citric acid chitosan modified polysulfone 15% (mass fraction, the same below), N-methylpyrrolidone 42%, N,N-dimethylacetamide 43%, into the raw material tank, at 25 ℃ Stir at low temperature for 15 hours. After fully dissolving, let stand at room temperature for defoaming for 18 hours to obtain a uniform film liquid;

[0030] Open the nitrogen valve, maintain the pressure of the raw material tank at 0.18MPa, filter the modified polysulfone membrane liquid, and press it into the spinning head through the metering pump, control the flow rate of the membrane liquid to 1.11mL / min, and feed the core liquid at the same time, the flow rate is 1.08mL / min; the nascent film enters the coagulation bath and rinsing bath under the traction of the winding machine after passing through the air gap of 18cm, and then is wound on the drum; the winding speed is 50m / min, and the coagulation bath temperature is 30℃ , the temperature of the rinsing bath was 30°C; the polysulfon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com