Preparation method of wood product corrosion-resistant paint

A corrosion-resistant, wood product technology, applied in the field of paint, can solve the problems affecting the appearance and service life of wood products, uneven paint film thickness, general corrosion resistance, etc., achieve good suspension and dispersion, and increase paint film thickness. , the effect of good electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

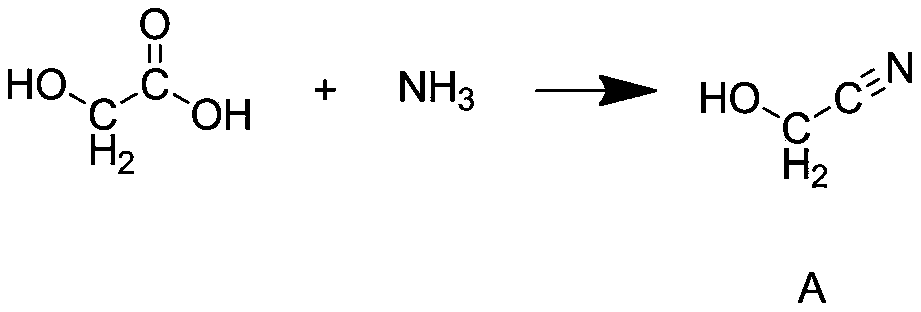

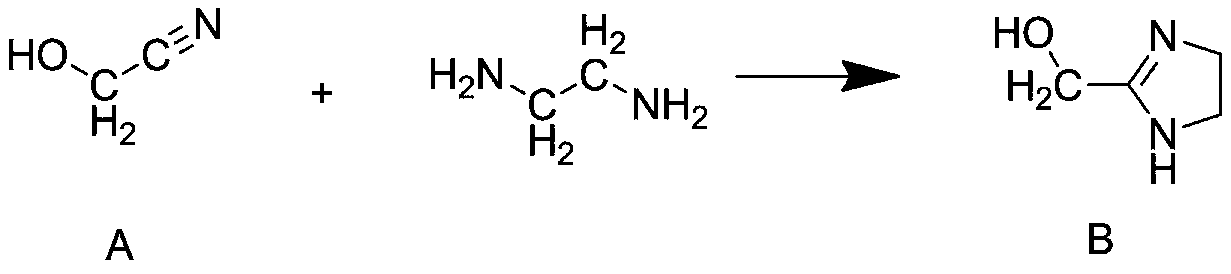

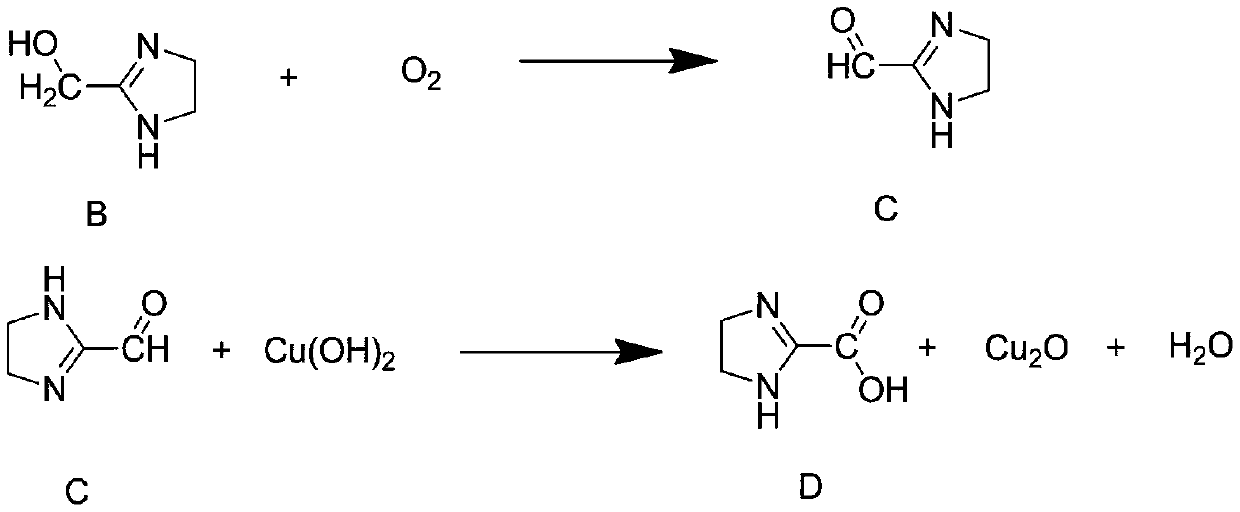

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a corrosion-resistant paint for wood products, comprising the steps of:

[0040] Step S1: According to the following parts by weight: 20 parts of bisphenol A epoxy resin, 15 parts of phenolic resin, 15 parts of alkyd resin, 15 parts of styrene, 4.5 parts of calcium carbonate, 7 parts of talc, 7.5 parts of kaolin, bentonite 5 parts, 7.5 parts of titanium dioxide, 0.01 part of dispersant, 12 parts of corrosion resistant agent, 4.5 parts of film-forming aid, 0.3 part of defoamer and weighed each raw material;

[0041]Step S2: Add bisphenol A epoxy resin, phenolic resin, and alkyd resin into the stirring tank, and heat for 30 minutes at a temperature of 80°C until the bisphenol A epoxy resin, phenolic resin, alkyd resin After the resin is completely melted, add styrene, stir for 15 minutes at a speed of 80 r / min, and a temperature of 80 ° C, and cool to room temperature to obtain a mixed solution;

[0042] Step S3: mix calcium carbonate, talcum powde...

Embodiment 2

[0052] A method for preparing a corrosion-resistant paint for wood products, comprising the steps of:

[0053] Step S1: According to the following parts by weight: 25 parts of bisphenol A epoxy resin, 20 parts of phenolic resin, 20 parts of alkyd resin, 18 parts of styrene, 6 parts of calcium carbonate, 8 parts of talcum powder, 10 parts of kaolin, bentonite 8 parts, 9 parts of titanium dioxide, 0.05 parts of dispersant, 15 parts of anti-corrosion agent, 8 parts of film-forming aid, 1 part of defoamer and weighed each raw material;

[0054] Step S2: Add bisphenol A epoxy resin, phenolic resin, and alkyd resin into the stirred tank, and heat for 40 minutes at a temperature of 85°C until the bisphenol A epoxy resin, phenolic resin, alkyd resin After the resin is completely melted, add styrene, stir for 20 minutes under the conditions of rotation speed of 100r / min and temperature of 85°C, and cool to room temperature to obtain a mixed solution;

[0055] Step S3: mix calcium carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com