Nano metal thermal-insulating membrane with low reflectance and low transmittance and preparation method of nano metal insulating membrane

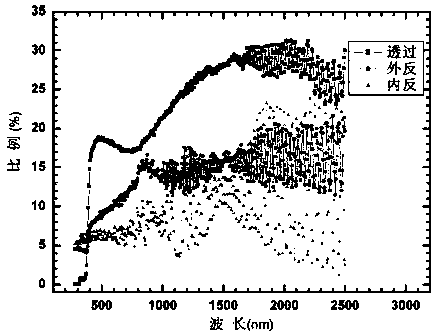

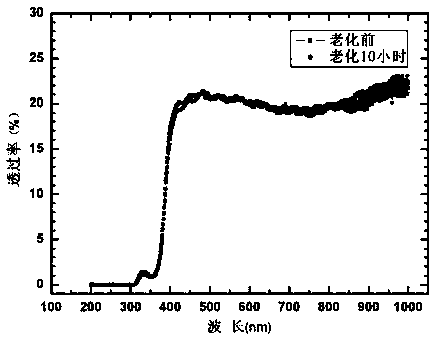

A nano-metal, light reflectance technology, applied in the direction of pressure-sensitive film/sheet, film/sheet adhesive, coating, etc., can solve the problem of reducing the internal reflectance of visible light, failing to meet national standards, and low infrared rejection rate, etc. problems, to achieve the effects of reducing the production process of the composite process, overcoming the deformation of the base film, and solving the problem of light pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also discloses a method for preparing a nano-metal thermal insulation film with low light reflectance and low light transmittance, which includes the following steps:

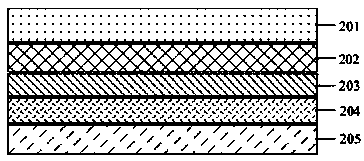

[0047] S1. Preparation of nickel-chromium base film: select a transparent PET with PU precoating and corona treatment on both sides and the haze is less than 1% as the base film, and plate it on the corona surface of the base film by magnetron sputtering A layer of nickel-chromium alloy, by controlling the thickness to obtain a nickel-chromium base film with a transmittance in the range of 30-60%, and its two sides are PU pre-coating and nickel-chromium layer;

[0048] S2. Preparation of inorganic pigment slurry: first mix and stir the dispersant and solvent in the pre-mixing tank, then pass it into the grinding chamber of the ball mill for grinding, and gradually add carbon black or silicon nitride titanium, and prepare carbon black slurry respectively after grinding material or si...

Embodiment 1

[0054] Base film selection: select a 36 μm thick PET base film with a haze of less than 1%, and its longitudinal and transverse heat shrinkage rates are 1.2% and 0.2%, respectively. The base film is corona treated on one side and pre-coated with PU coating on the other side.

[0055]Preparation of nickel-chromium coating: A layer of nickel-chromium (20% chromium) alloy is plated on the corona surface of the PET base film by magnetron sputtering. Through thickness control, nickel with a visible light transmittance of about 43% is obtained. Chromium base film.

[0056] Preparation of silicon nitride titanium slurry: Weigh 10 parts of silicon nitride titanium with a particle size of 20nm (the doping ratio of silicon is 10%), 2 parts of a small molecule dispersant with a molecular weight of 800, and a polymer dispersion with a molecular weight of 5000. 7 parts of dispersant and 81 parts of ethyl acetate, first mix the dispersant and solvent in the premix tank for 15 minutes, then...

Embodiment 2

[0063] The main difference between Example 2 and Example 1 is that cesium tungsten oxide high heat insulation nanomaterials are added to the scratch-resistant layer, so the difference from Example 1 is that it is necessary to prepare cesium tungsten oxide slurry and UV-curable coating, and the remaining materials and preparation It is the same as that in Embodiment 1 and will not be repeated here.

[0064] Preparation of cesium tungsten oxide slurry: Weigh 20 parts of cesium tungsten oxide with a particle size of 50nm (the doping ratio of cesium is 5%), 10 parts of a polymer dispersant with a molecular weight of 10000 and 70 parts of ethyl acetate. The agent and the solvent were mixed and stirred in the premixing tank for 15 minutes, then cesium tungsten oxide was gradually added, and stirred at 1000RPM for 15 minutes, and finally circulated into the grinding chamber of an 8-liter ball mill through a pneumatic diaphragm pump for grinding, with an online speed of 14m / s In the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com