Preparation method of mesoporous silica long-acting antibacterial nano-materials with high selenium loading amount

A technology of mesoporous silica and nanomaterials, which is applied in the fields of botanical equipment and methods, chemicals for biological control, plant growth regulators, etc., can solve the problem that selenium cannot be uniformly loaded in large quantities, and achieve good bactericidal effect. , Enlarged aperture, the effect of controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

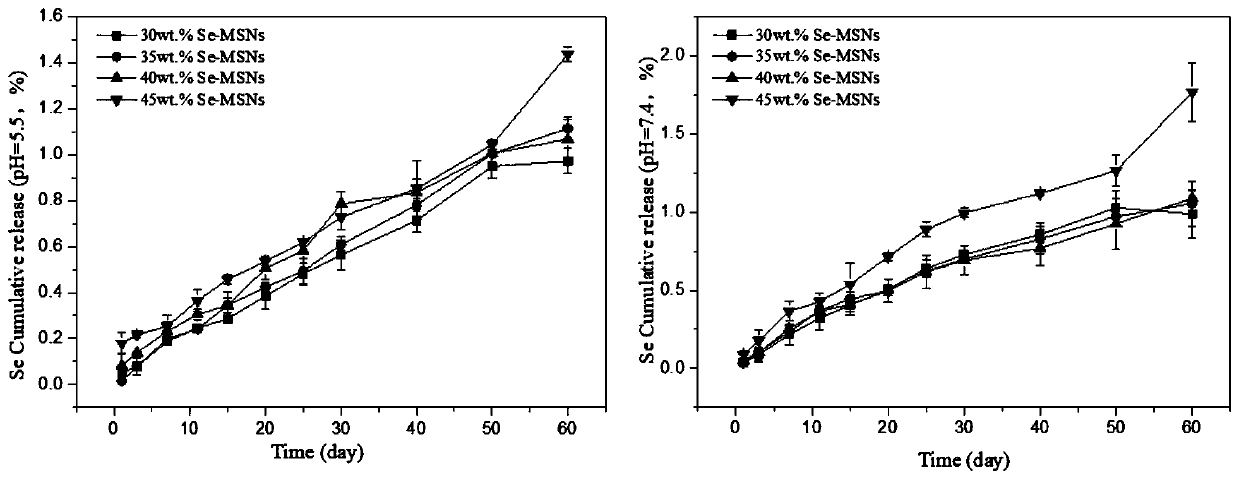

[0043] Select analytically pure sodium selenite, ascorbic acid, cetyltrimethylammonium bromide (CTAB, Sinopharm Group Industry Co., Ltd.), ammonium fluoride (NH 4 F, Sinopharm Group Industry Co., Ltd.), tetraethyl orthosilicate (TEOS, Sinopharm Group Industry Co., Ltd.), and Se-MSNs with a Se loading of 30wt.% were synthesized by this preparation method. The specific steps are:

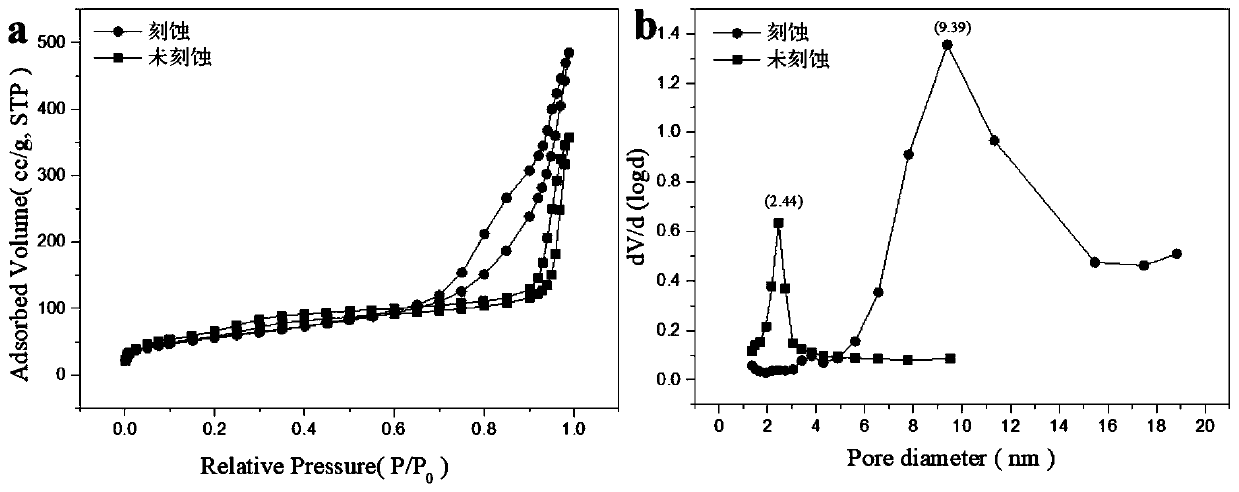

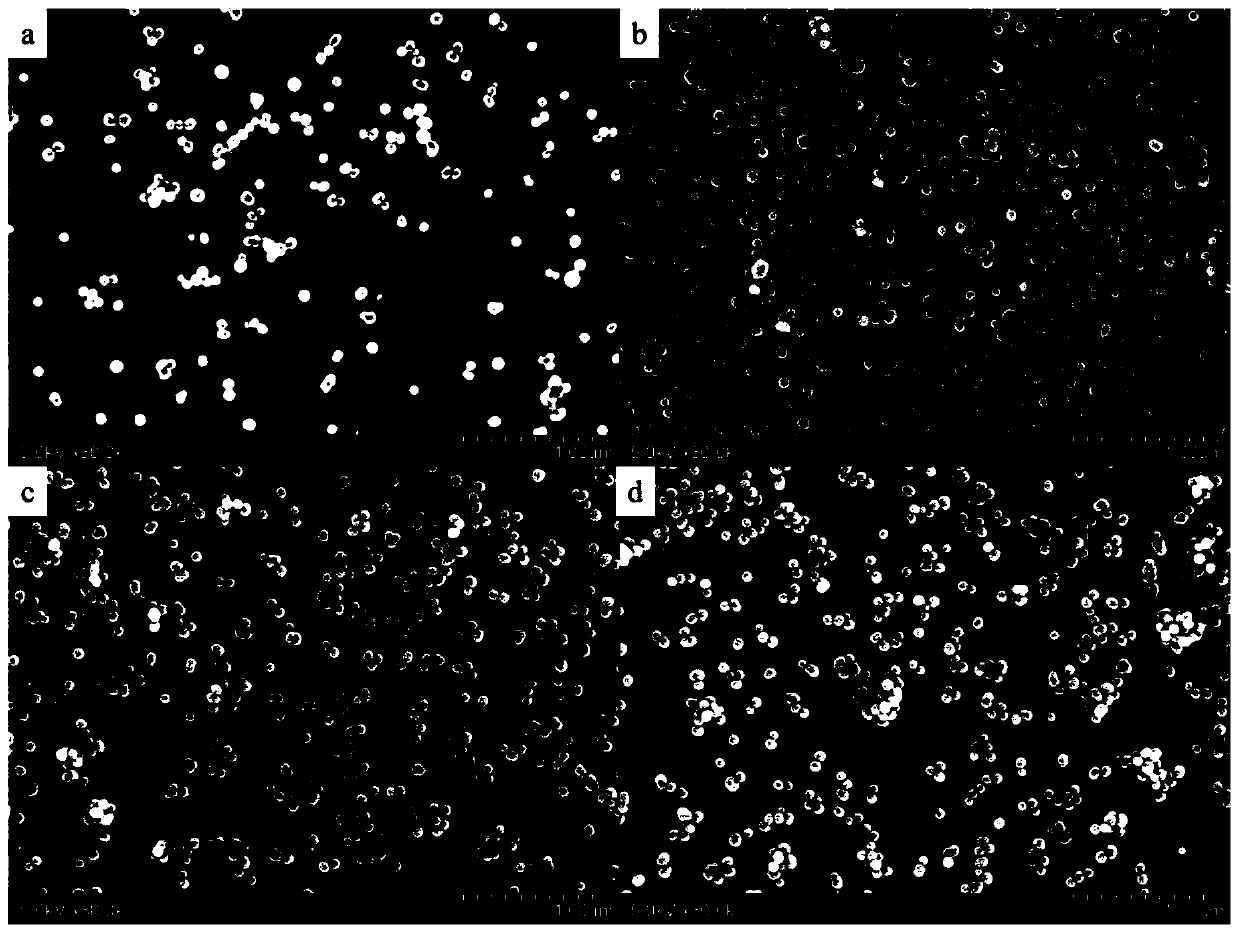

[0044] Weigh 0.90g CTAB, 1.50g NH 4 F, then add 250mL of deionized water, the reaction temperature is 80°C, stir well for 1h, the rotor speed is controlled at 200-300rpm; after 1h of reaction, add 1.8mL of TEOS dropwise to the reaction system, continue the reaction for 1h, then cool to room temperature The sample was centrifuged, and the white powder obtained by freeze-drying the precipitate was calcined in a muffle furnace at 600°C for 5 hours to remove CTAB in MSNs; 1.59g of anhydrous sodium carbonate was dissolved in 50mL of deionized water to obtain a concentration of 0.3mol / L under stirring con...

Embodiment 2

[0047] Se-MSNs with a selenium loading of 20wt.% were synthesized by this preparation method. The specific steps are:

[0048] The preparation method of the expanded MSNs is the same as in Example 1.

[0049] According to Example 1, the amount of sodium selenite was changed to 0.25g, the amount of ascorbic acid was changed to 0.75g, and the rest were the same as in Example 1 to obtain red powder 20wt.%Se-MSNs.

[0050] After testing, the results of its antibacterial properties are similar to those of Example 1.

Embodiment 3

[0052] Se-MSNs with a selenium loading of 35wt.% were synthesized by this preparation method. The specific steps are:

[0053] The preparation method of the expanded MSNs is the same as in Example 1.

[0054] According to Example 1, the amount of sodium selenite was changed to 0.437g, the amount of ascorbic acid was changed to 1.29g, and the rest were the same as in Example 1 to obtain a red powder of 35wt.% Se-MSNs.

[0055] After testing, the results of its antibacterial properties are similar to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com