Method for detecting residual pesticide content in dairy product

A technology for residual pesticides and dairy products, applied in measurement devices, separation methods, chemical instruments and methods, etc., can solve the problems of time-consuming and labor-intensive, cumbersome extraction process, loss of target substances, etc. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

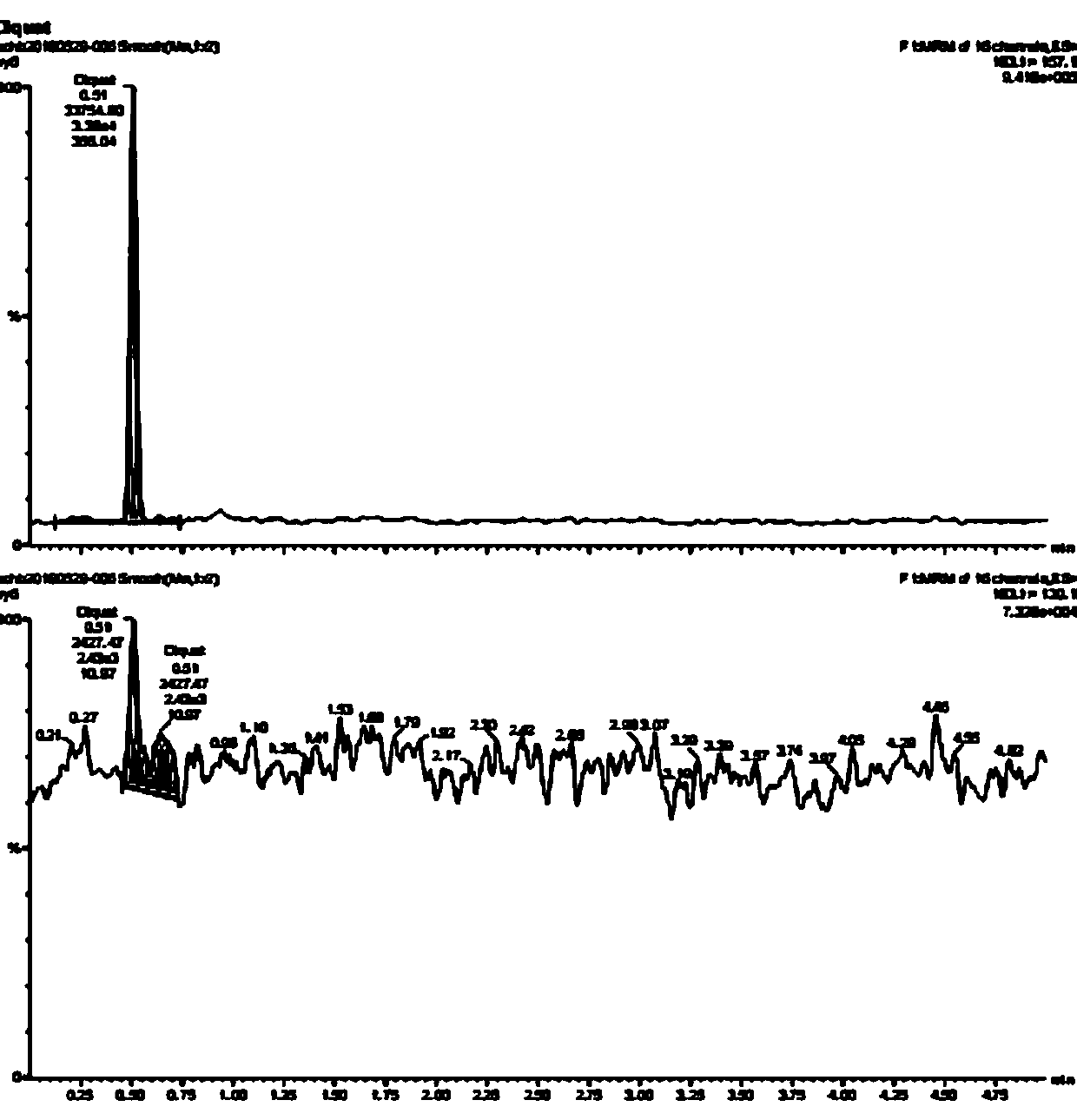

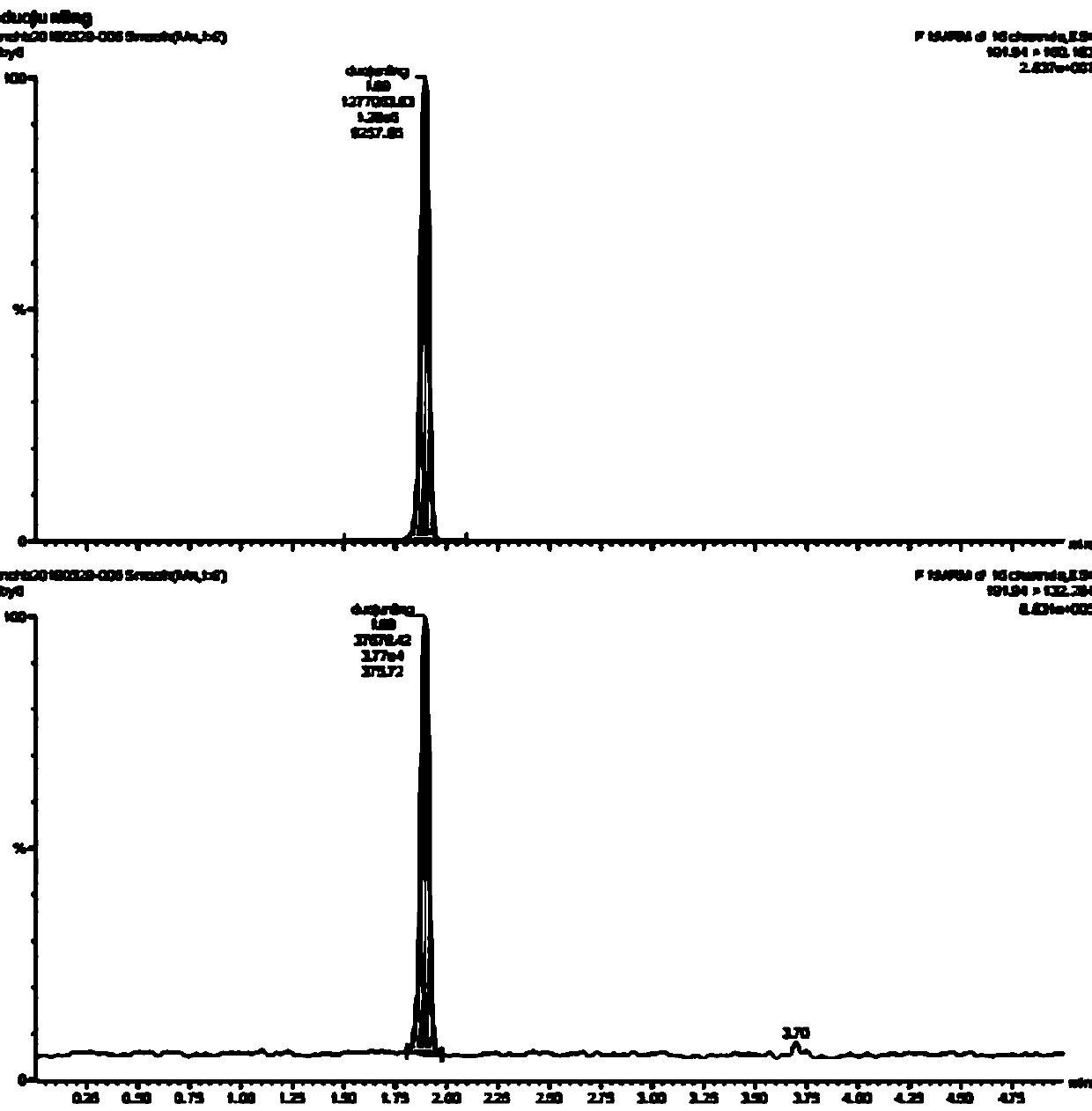

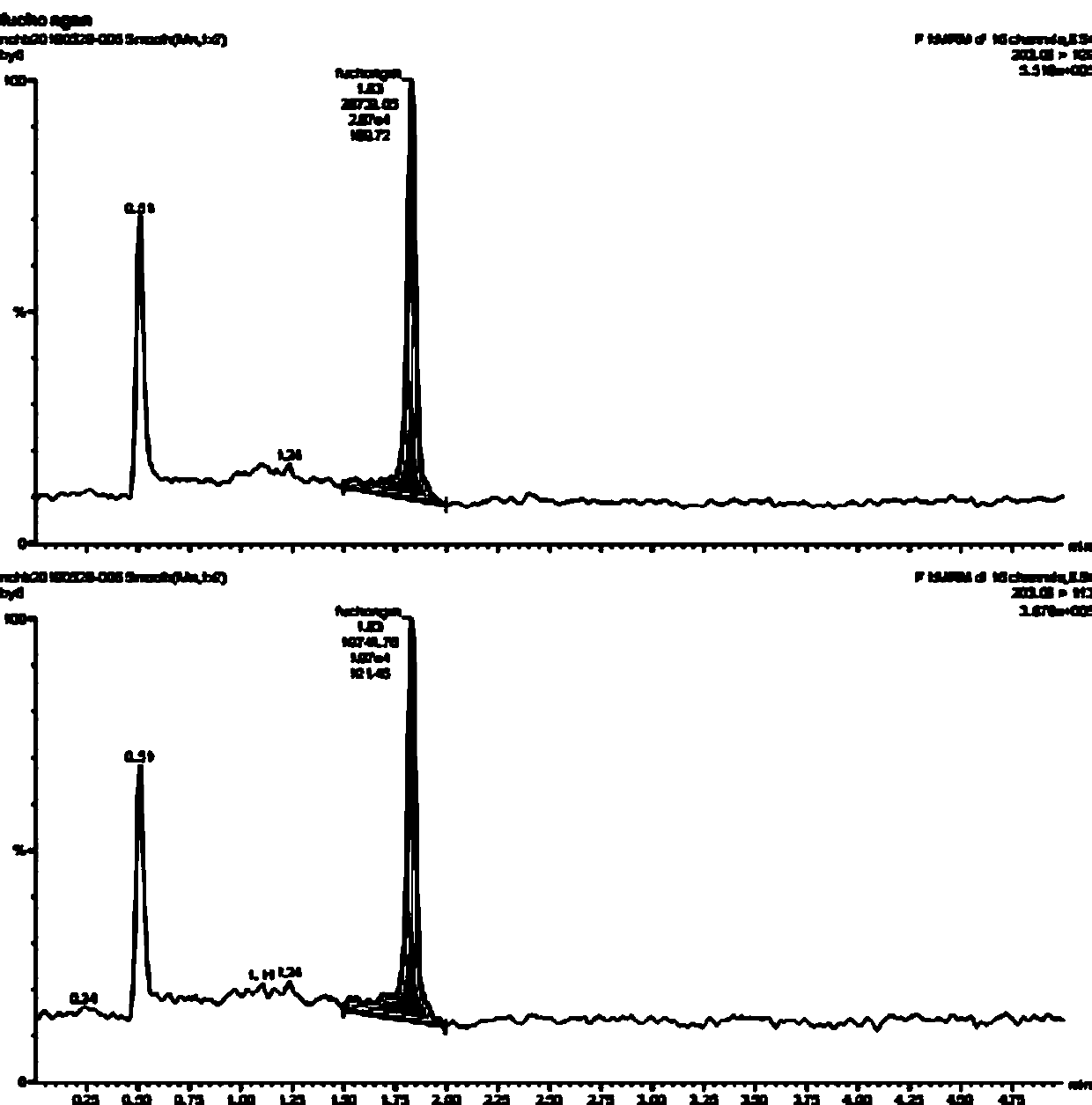

Image

Examples

Embodiment 1

[0033] Example 1 A method for detecting the content of residual pesticides in dairy products

[0034] The reagents used in this example are acetonitrile (chromatographically pure, Fisher Scientific), formic acid (chromatographically pure, SIGMA-ALDRICH), ammonium acetate (chromatographically pure, SIGMA-ALDRICH), n-hexane (chromatographically pure, Dima Company), glacial acetic acid (chromatographically pure, Tianjin Kemiou Chemical Reagent Co., Ltd.), magnesium sulfate, sodium chloride, anhydrous sodium acetate, anhydrous magnesium sulfate, anhydrous sodium sulfate (burn at 650°C for 4 h and store in a desiccator for later use): Analytical grade, Tianjin Yongda Chemical Reagent Co., Ltd. PSA (Primarysecondary amine N-propylethylenediamine) filler, particle size 40-60 μm; C18 (octadecylsilane bonded phase), particle size 40-60 μm.

[0035] Pesticide standard products are carbendazim, diquat dibromide, spinosad, diflubenzuron, dinotefuran, emamectin benzoate, sulfoxaflor, prot...

Embodiment 2-5

[0069] Example 2-5 A method for detecting the content of residual pesticides in dairy products

[0070] Examples 2-5 are respectively a method for detecting the residual pesticide content in dairy products. The detection method is the same as that of Example 1, except that the parameters in the process of configuring and measuring the sample liquid D to be tested are different. See the table for details. 6:

[0071] Table 6 List of parameters

[0072]

[0073] Measured according to the steps and conditions in the above table, the results are as follows,

[0074] The measurement result of embodiment 2:

[0075] (1) Qualitative measurement results:

[0076] Measured according to the method of Example 1, by comparing the retention times of various pesticides in the sample and the standard, they are basically the same, with a deviation of ≤ 2.5%, and the maximum allowable deviation of the relative ion abundance during qualitative confirmation meets the requirements.

[0077...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com