Carbon self-coated micron-sized tungsten oxide, negative electrode material, battery and preparation method

A carbon self-coating and tungsten oxide technology, which is applied in the preparation/purification of carbon, tungsten oxide/tungsten hydroxide, battery electrodes, etc., can solve the problems of low specific capacity and poor cycle stability of electrode materials, and achieve uniform particle size , Stable charge and discharge, solve the effect of low specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

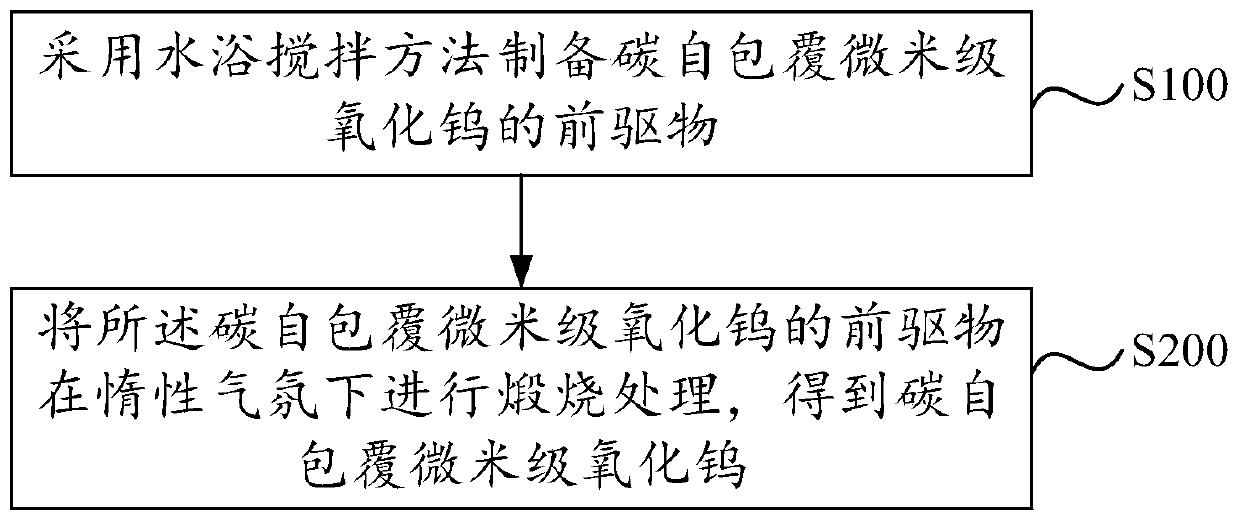

[0041] figure 1 A schematic flow chart of a carbon self-coated micron-scale tungsten oxide preparation method provided in the examples of this application, as shown in figure 1 As shown, the method mainly includes the following steps.

[0042] Step S100: Prepare carbon self-coated micron tungsten oxide precursor by self-polymerization reaction with stirring in a water bath.

[0043] In an optional embodiment, the preparation of carbon self-coated micron-sized tungsten oxide precursor by reaction includes:

[0044] Step S101: adding carbon source and tungsten source into the dispersant to disperse and mix to obtain a mixed solution.

[0045] In an optional embodiment, the carbon source is a mixture of two or more of dopamine hydrochloride, polyvinylpyrrolidone and urotropine; the tungsten source is sodium tungstate, lithium tungstate and tungsten One or a mixture of two or more in ammonium acid; the dispersant is one or a mixture of absolute ethanol and deionized water.

[...

Embodiment 1

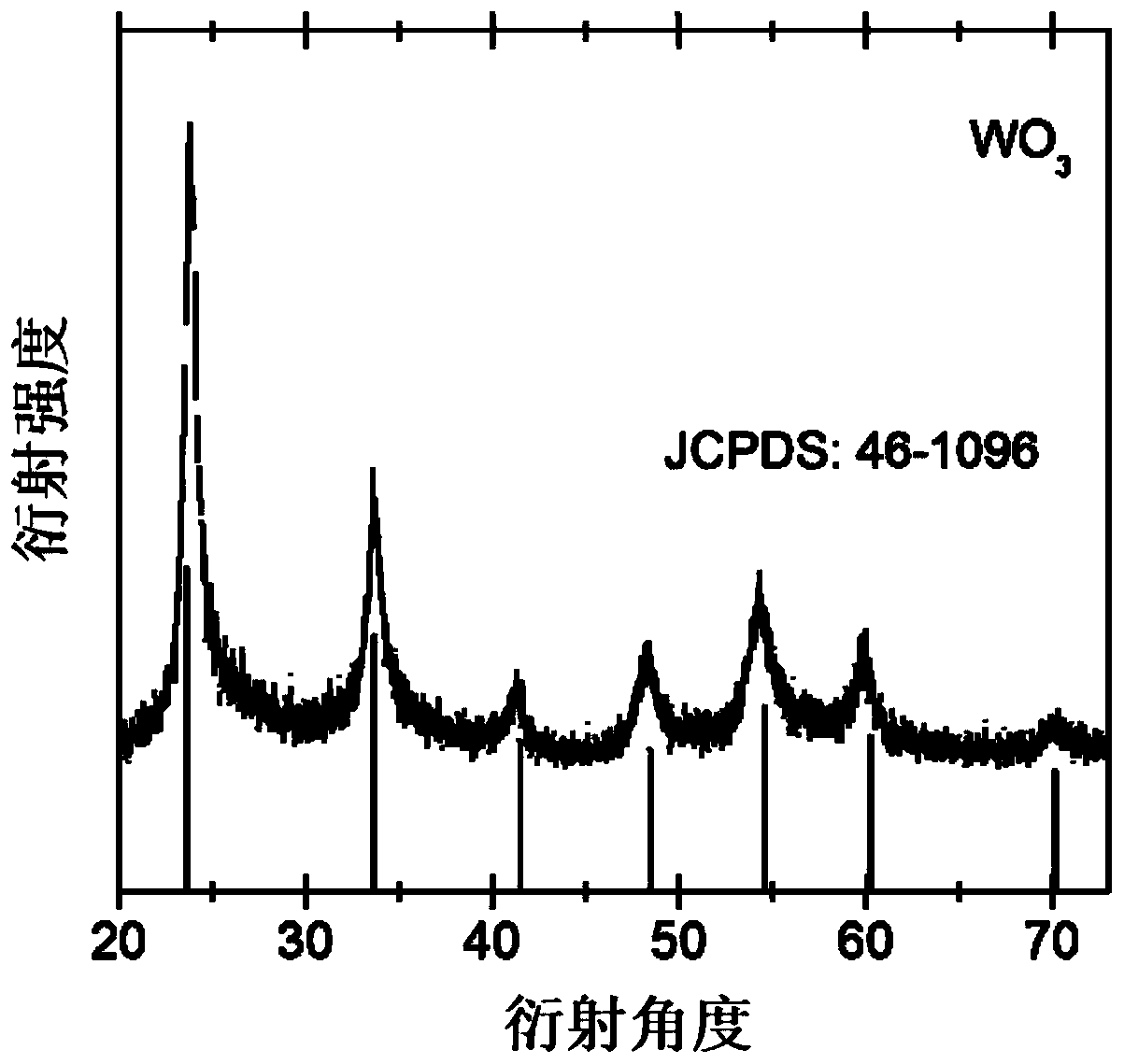

[0067] At room temperature, add 0.4g of tungstic acid, 1g of polyvinylpyrrolidone and 0.1g of PDA to the mixed solution of 100mL of water and 150mL of ethanol to disperse and mix. After stirring for 5 years, take 80mL of the above solution in a 100mL beaker for self-polymerization with water bath stirring For the reaction, the reaction temperature is 50° C., and the holding time is 5 hours. After the reaction is completed, the product is subjected to centrifugal drying treatment, and then vacuum-dried at 60° C. for 12 hours. Then place the dried sample in a porcelain boat at 500°C, with a heating rate of 2°C min -1 , The holding time is 2h, and the sintering atmosphere is argon.

Embodiment 2

[0069] At room temperature, add 0.5g tungstic acid, 1g polyvinylpyrrolidone and 0.1g PDA to the mixed solution of 100mL water and 150mL ethanol to disperse and mix. For the polymerization reaction, the reaction temperature is 80° C., and the holding time is 5 hours. After the reaction is completed, the product is subjected to centrifugal drying treatment, and then vacuum-dried at 60° C. for 12 hours. Then place the dried sample in a porcelain boat at 500°C, with a heating rate of 2°C min -1 , The holding time is 2h, and the sintering atmosphere is argon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com