A kind of lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as equipment damage, explosion, battery capacity attenuation, etc., and achieve the effects of reducing gas generation, improving safety performance, and reducing thickness expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

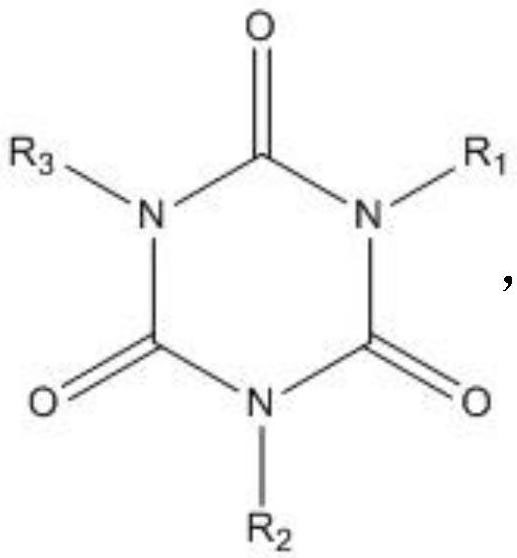

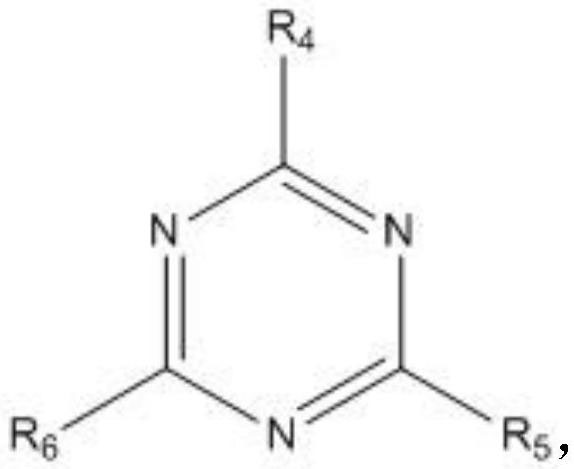

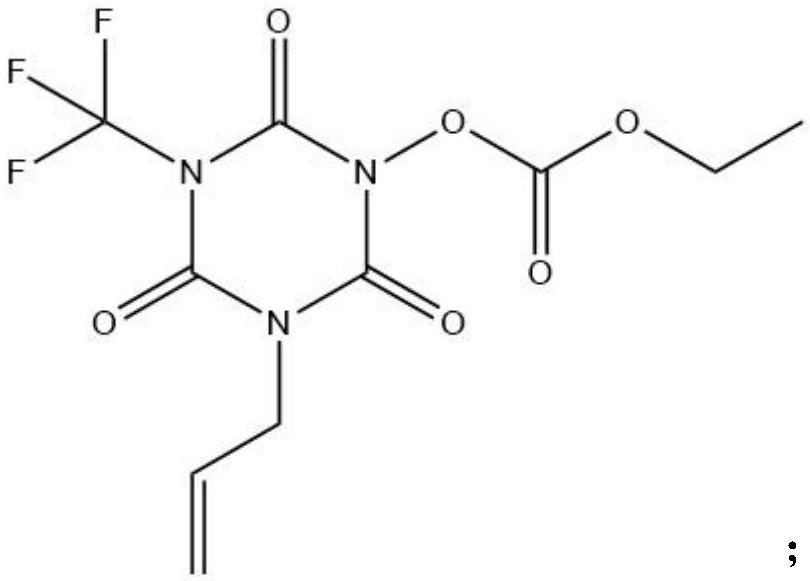

Method used

Image

Examples

Embodiment 1

[0040] (1) Positive electrode preparation: mix the high-voltage 4.40V ternary 532 positive electrode active material, CNTs (carbon nanotubes) and PVDF (polyvinylidene fluoride) according to the mass ratio of 98.0:0.8:1.2, and then disperse them in N-methyl - 2-pyrrolidone to obtain positive electrode slurry; apply the positive electrode slurry evenly on both sides of the aluminum foil, dry, roll, and cut to obtain the positive electrode sheet, and finally bake and vacuum dry it for use.

[0041] (2) Negative electrode preparation: Mix artificial graphite negative electrode material, acetylene black, CMC (carboxymethyl cellulose), SBR (carboxylated styrene-butadiene rubber) according to the mass ratio of 96.8:1.0:1.2:1.0, and then disperse them in deionized water , to obtain the negative electrode slurry; the negative electrode slurry is evenly coated on both sides of the copper foil, and after drying, rolling, and cutting, the negative electrode sheet is obtained, and finally i...

Embodiment 2

[0045] Different from Example 1 is the preparation of electrolyte: in the glove box (O) that is full of nitrogen 2 2 (0<3ppm), mix ethylene carbonate, propylene carbonate, ethyl methyl carbonate, and diethyl carbonate according to the mass ratio of 2:2:4:2 to obtain a non-aqueous organic solvent; A non-aqueous organic solvent with a mass of 78.5%, to which 1% vinylene carbonate, 2% fluoroethylene carbonate, 1% adiponitrile, 1% 1,3,6-hexane Alkane trinitrile and 0.5% cyanuric acid ester compound B1 to obtain a mixed solution; then slowly add lithium hexafluorophosphate accounting for 15% of the total mass of the electrolyte and 0.5% of the total mass of the electrolyte Lithium difluorooxalate borate to the mixed solution and a mixture of lithium difluorophosphate accounting for 0.5% of the total mass of the electrolyte, and the electrolyte is prepared after being uniformly mixed.

[0046] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0048] Different from Example 1 is the preparation of electrolyte: in the glove box (O) that is full of nitrogen 2 2 O<3ppm), mix ethylene carbonate, butylene carbonate, ethyl methyl carbonate, diethyl carbonate, propyl acetate, and ethyl monofluoroacetate in a mass ratio of 2:2:3:2:0.5:0.5 Uniformly, the non-aqueous organic solvent is obtained; Then get the non-aqueous organic solvent accounting for 78% of the total mass of the electrolytic solution, add 1% vinylene carbonate, 2% fluoroethylene carbonate, 0.5% based on the total mass of the electrolytic solution, wherein % of 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether, 1% of adiponitrile, 1% of 1,3,6-hexanetrinitrile, 0.25 % isocyanurate compound A2 and 0.25% cyanurate compound B2 to obtain a mixed solution; then slowly add lithium hexafluorophosphate accounting for 15% of the total mass of the electrolyte to the mixed solution, accounting for 0.5% of the total mass of the electrolyte % of lithium bisoxalate bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com