Acne-removing composition and preparation method thereof

A composition and acne technology, applied in the direction of drug combination, skin care preparations, medical preparations containing active ingredients, etc., can solve the problem that alcohol-soluble components cannot be effectively extracted, 5α-reductase is not considered, and cannot be effective The components are fully extracted to achieve the effect of inhibiting Propionibacterium acnes, improving the utilization rate of medicinal materials, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Put 20 parts of Cortex Phellodendron into a pulverizer, crush it to a size of 80 mesh or less (sieve); put in pure water 6 times the weight of the medicinal material, and stir to suspend and disperse the particles;

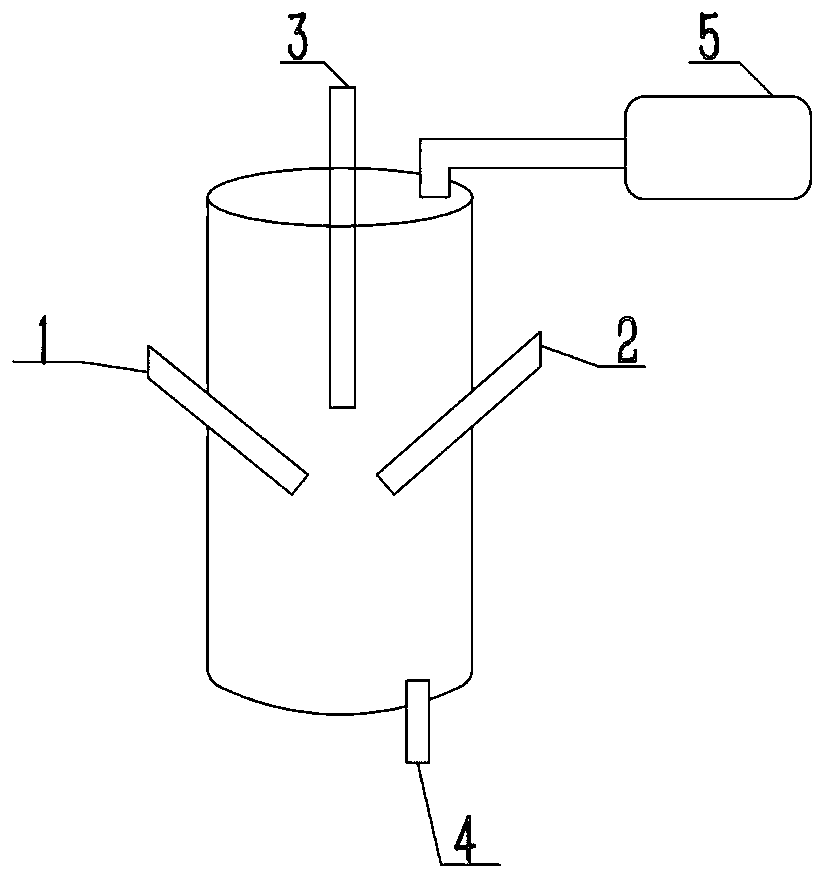

[0045] 2. Jet cooking the material liquid in 1, the material is in the middle, steam is injected from both sides, the steam outlets on both sides are at an angle of 120°, the steam temperature is 140°C, the material flow rate is 15L / min, and the steam flow rate on both sides is 20L / min min;

[0046] 3. Pour the material liquid in 2 into the colloid mill, the grinding gap gradually decreases from the maximum (the gap finally reaches 1 micron), heat the material liquid to 40°C, add cellulase according to 0.8% of the weight of the medicinal material (enzyme activity unit 10000 U / g), adjust the pH to 4.5, stir for enzymolysis and grind for 60 minutes;

[0047] 4. Add butanediol which is 6 times the weight of Phellodendron cortex in 1, and 20 parts of thyme...

Embodiment 2

[0053] 1. Put 15 parts of Cortex Phellodendron into a pulverizer, crush it to less than or equal to 80 mesh (sieve); put in pure water 4 times the weight of the medicinal material, and stir to suspend and disperse the particles;

[0054] 2. Put the material liquid in 1 into the steam injection device for jet cooking, the steam temperature is 120°C, the material flow rate is 20L / min, and the steam flow rate on both sides is 25L / min;

[0055] 3. Pour the material liquid in 2 into the colloid mill, the grinding gap gradually decreases from the maximum (the gap finally reaches 1 micron), heat the material liquid to 30°C, add cellulase according to 0.1% of the weight of the medicinal material (enzyme activity unit 10000 U / g), adjust the pH to 5.5, stir and grind for 60 minutes;

[0056] 4. Add butanediol which is 4 times the weight of Phellodendron cortex in 1, and 15 parts of thyme, mix well, continue grinding and extracting at 55°C for 0.5h;

[0057] 5. Use qualitative filter p...

Embodiment 3

[0060] 1. Put 17.5 parts of Cortex Phellodendron into a pulverizer, crush to a size of 80 mesh or less (sieve); put in pure water 5 times the weight of the medicinal material, and stir to suspend and disperse the particles;

[0061] 2. Put the material liquid in 1 into the steam injection device for jet cooking, the steam temperature is 130°C, the material flow rate is 18L / min, and the steam flow rate on both sides is 22L / min;

[0062] 3. Pour the material liquid in 2 into the colloid mill, the grinding gap gradually decreases from the maximum (the gap finally reaches 1 micron), heat the material liquid to 50°C, add cellulase according to 0.5% of the weight of the medicinal material (enzyme activity unit 10000 U / g), adjust the pH to 4.0, stir for enzymolysis and grind for 60 minutes;

[0063] 4. Add butanediol which is 4 times the weight of Phellodendron cortex in 1, and 17.5 parts of thyme, mix well, continue grinding and extracting at 30°C for 0.5h;

[0064] 5. Use qualita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com