Biomass-based adsorption material, preparation method and application thereof

A technology for biomass and oil-absorbing materials, applied in the field of biomass-based adsorption materials and their preparation, achieves the effects of rapid adsorption, wide sources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

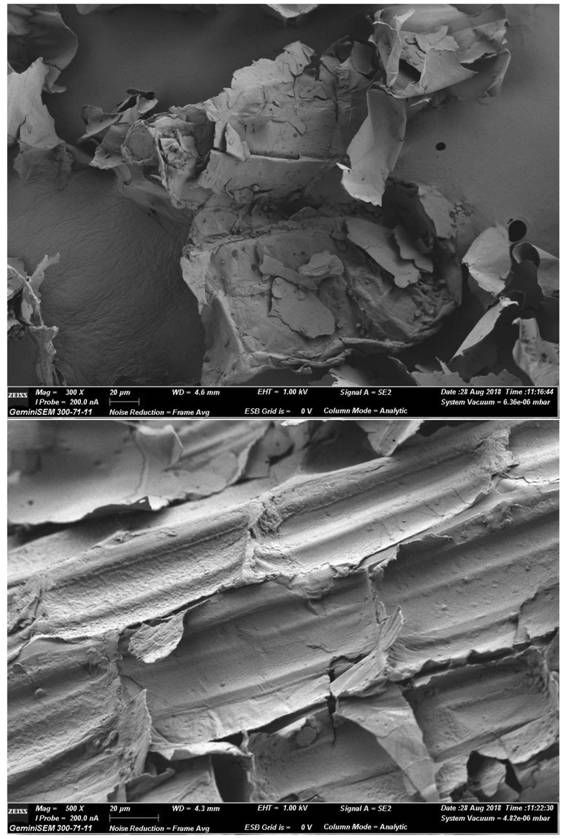

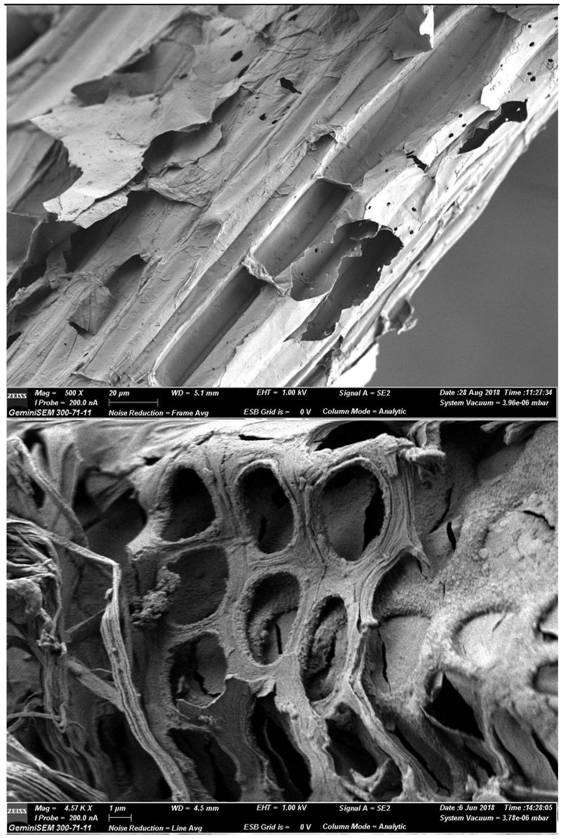

[0041] (1) Wash and air dry the corn stalks produced in Baise City, Guangxi Province;

[0042] (2) get the straw obtained in step (1), manually separate the skin and the pith, then pulverize the pith, and pass through a 40-mesh sieve to obtain corn stalk pith particles;

[0043] (3) take the corn stalk pith particles obtained in step (2) and add them to 90°C hot water, stir for 1 hour, wash with distilled water to neutrality after swelling, and dry;

[0044] (4) Mix the swollen straw particles with the acetic acid-sodium acetate buffer solution of pH=4.8 according to the ratio of corn straw pith to the buffer solution mass-volume ratio of 1:50, the unit is g / mL, add the same amount as in step 1 The mass ratio of corn stalks in 3.5% TEMPO, oxygenated, and shaken at 150 rpm for 1 h at 45 °C;

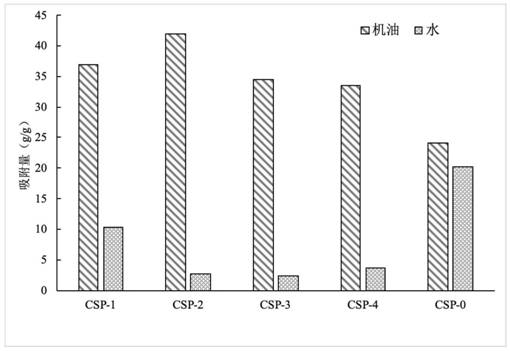

[0045] (5) Then stearylamine and laccase A (from Trametes versicolor) were added to make stearylamine (octadecylamine, C 18 H 39 N): Enzyme activity: corn stalk pith=0.16:100:1, the uni...

Embodiment 2

[0049] (1) Wash and air dry the corn stalks produced in Baise City, Guangxi Province;

[0050] (2) get the straw obtained in step (1), manually separate the skin and the pith, then pulverize the pith, and pass through a 40-mesh sieve to obtain corn stalk pith particles;

[0051] (3) take the corn stalk pith particles obtained in step (2) and add them to 90°C hot water, stir for 1 hour, wash with distilled water to neutrality after swelling, and dry;

[0052] (4) Mix the swollen straw particles with the acetic acid-sodium acetate buffer solution of pH=4.8 according to the ratio of corn straw pith to the buffer solution mass-volume ratio of 1:50, the unit is g / mL, add in step 1 The corn stover pith mass ratio was 3.5% TEMPO, oxygenated, and shaken at 150 rpm for 1 h at 45 °C;

[0053] (5) Then add stearylamine and laccase A (produced from Trametes versicolor), so that stearylamine: enzyme activity: straw=0.24:100:1, the unit is g:U:g, and the temperature is controlled at 45°C ...

Embodiment 3

[0058] (1) Wash and air dry the corn stalks produced in Baise City, Guangxi Province;

[0059] (2) get the straw obtained in step (1), manually separate the skin and the pith, then pulverize the pith, and pass through a 40-mesh sieve to obtain corn stalk pith particles;

[0060] (3) take the corn stalk pith particles obtained in step (2) and add them to 90°C hot water, stir for 1 hour, wash with distilled water to neutrality after swelling, and dry;

[0061] (4) Mix the swollen straw particles with the acetic acid-sodium acetate buffer solution of pH=4.8 in a ratio of 1:50 in mass volume ratio of corn straw pith to the buffer solution, the unit is g / mL, and the amount added is equal to the mass of the straw. The ratio is 3.5% TEMPO, oxygenated, and shaken at 150 rpm for 1 h at 45 °C;

[0062] (5) Then add stearylamine and laccase A (produced from Trametes versicolor), so that stearylamine: enzyme activity: straw=0.36:100:1, the unit is g:U:g, and the temperature is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com