Catalyst for catalyzing oxidation of benzyl compound to prepare carbonyl compound and preparation method and application of catalyst

A carbonyl compound, catalyzed benzyl technology, applied in the preparation of carbonyl compounds, the preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of catalytic activity, low specific surface area of transition metal oxides, etc., to achieve catalyst performance Excellent, high selectivity of reaction products, simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

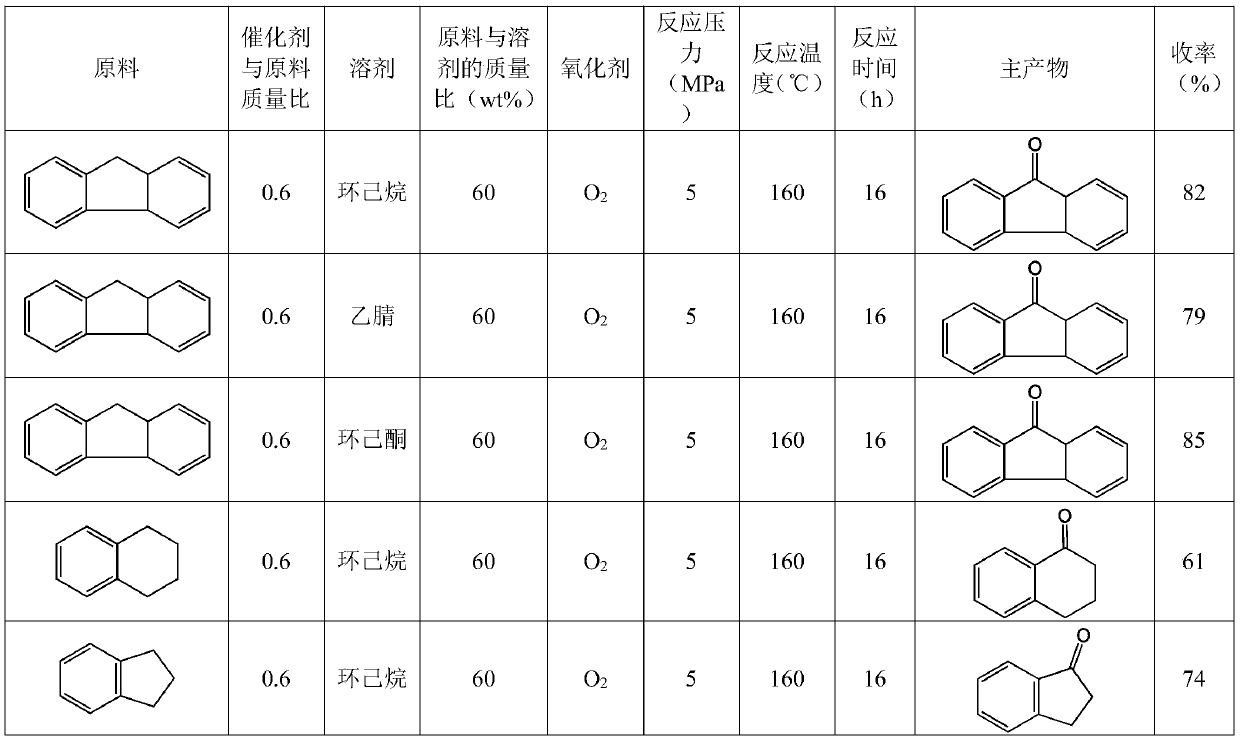

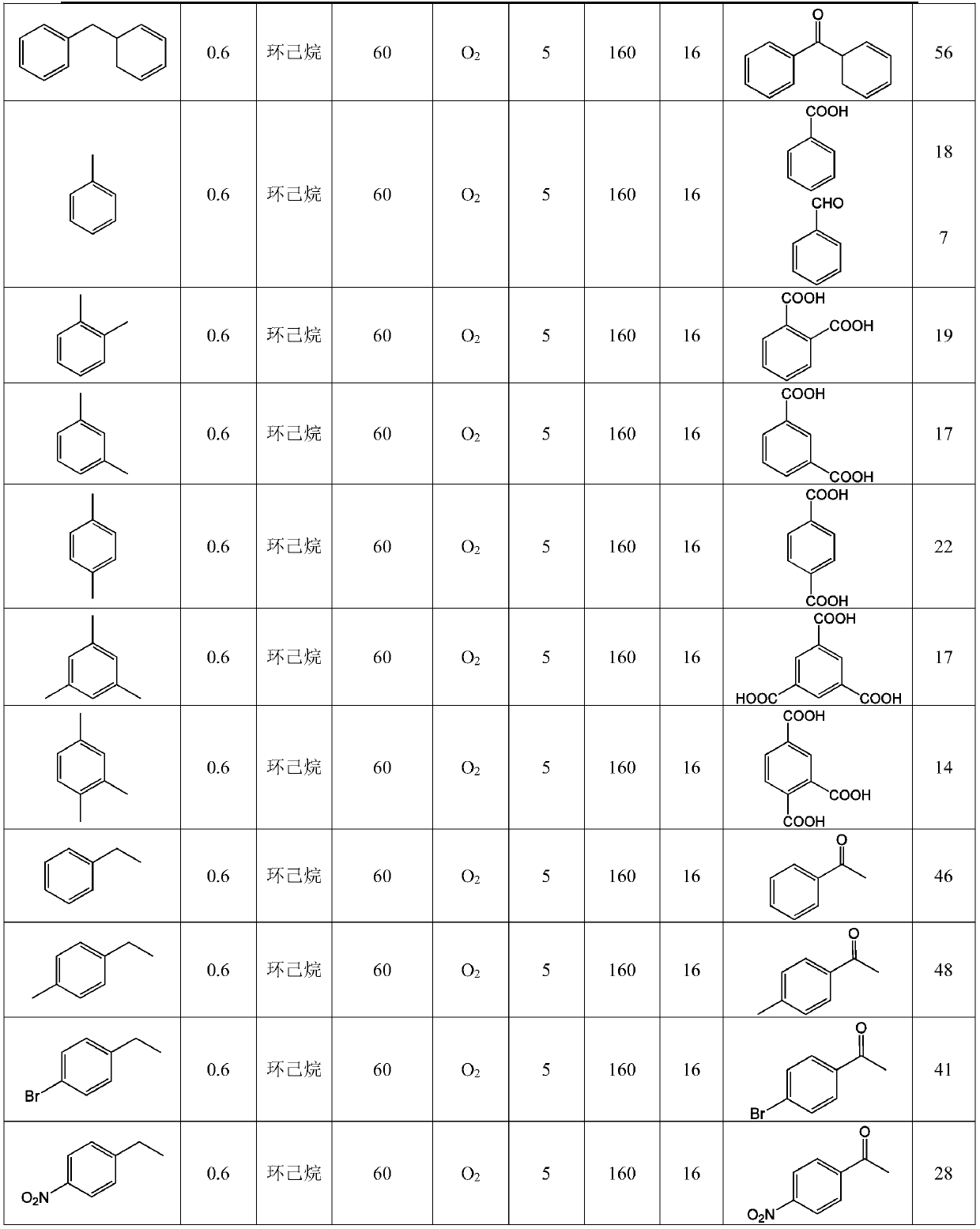

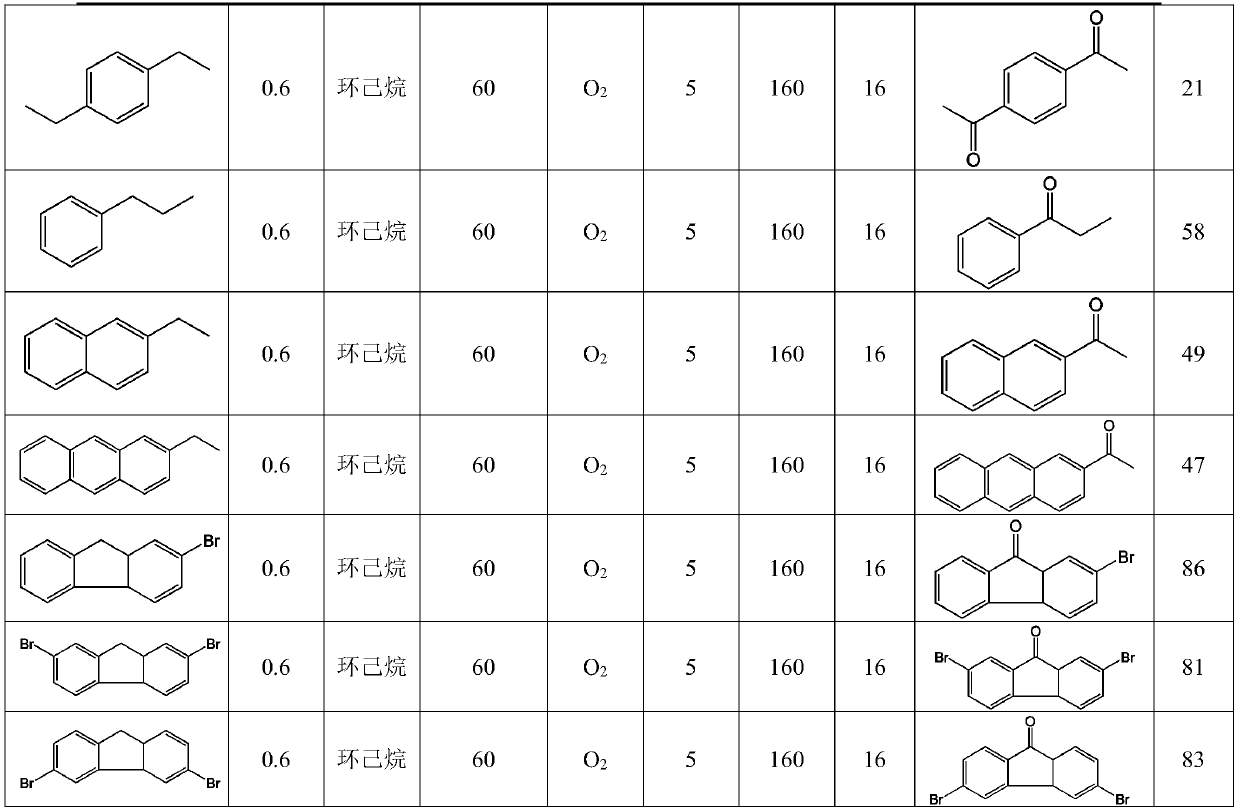

Examples

Embodiment 1

[0032] Prepare an aqueous solution of 60wt% cobalt nitrate, slowly add the silicon-based mesoporous molecular sieve hard template KIT-6 into the precursor solution at 90°C, the mass ratio of soluble salt to hard template is 1:2, keep stirring during the process, Continue to stir for 24 hours after adding the template agent, then stir the suspension at 90°C, evaporate the solvent to dryness, dry the obtained product at 150°C for 24 hours, and calcinate at 800°C for 10 hours, and continue to add the same amount of solid as before The aqueous solution of 60wt% cobalt nitrate was repeatedly impregnated under the same conditions as before, the solvent was evaporated, dried and calcined to obtain a silicon-based mesoporous molecular sieve filled with metal oxides. Then use 5molL -1 The sodium hydroxide aqueous solution was removed at 90°C to remove the silicon-based mesoporous molecular sieve, then filtered, washed with deionized water until the filtrate was neutral, and dried at 15...

Embodiment 2

[0037] Prepare a 5wt% ethanol solution of copper nitrate, slowly add the silicon-based mesoporous molecular sieve hard template KIT-6 into the precursor solution at 20°C, the mass ratio of soluble salt to hard template is 1:0.2, and keep stirring during the process After the addition, continue to stir at 20°C for 2h, then stir the suspension at 50°C, evaporate the solvent to dryness, dry the obtained product at 50°C for 2h, and calcinate at 300°C for 1h, and continue to add the obtained solid with The same amount of 5wt% copper nitrate ethanol solution was repeatedly impregnated under the same conditions as before, evaporated to dryness, dried and calcined to obtain a silicon-based mesoporous molecular sieve filled with metal oxides. Then use 0.2molL -1 The sodium hydroxide aqueous solution was removed at 30°C to remove the silicon-based mesoporous molecular sieve, filtered, washed with deionized water until the filtrate was neutral, and dried at 50°C for 2 hours to obtain a c...

Embodiment 3

[0042] Prepare 30wt% ethanol solution of cobalt nitrate and copper nitrate, the molar ratio of cobalt to copper is 1:1, slowly add the silicon-based mesoporous molecular sieve hard template KIT-6 into the precursor solution at 55°C, the soluble salt and The mass ratio of the hard template agent is 1:1, keep stirring during the process, continue to stir at 55°C for 12h after the addition, then stir the suspension at 70°C, evaporate the solvent to dryness, and dry the obtained product at 100°C for 12h , calcined at 550°C for 6h, and the obtained solid was continuously added with the same amount of ethanol solution of 30wt% cobalt nitrate and copper nitrate as before, the molar ratio of cobalt and copper was 1:1, and the impregnation was repeated under the same conditions as before, The solvent is evaporated to dryness, dried and calcined to obtain a silicon-based mesoporous molecular sieve filled with metal oxides. Then use 2.5molL -1 The sodium hydroxide aqueous solution was r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com