Method for preparing hexagonal rare earth tetrafluoride sodium salt material through low-temperature molten salt fluorination

A technology of rare earth tetrafluoride and low temperature molten salt, which is applied in chemical instruments and methods, luminescent materials, rare earth metal compounds, etc., can solve the problems of requiring a large amount of organic solvents and surfactants, complicated preparation methods, etc., and achieve rich raw materials. , The reaction principle is simple, and the particle size is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

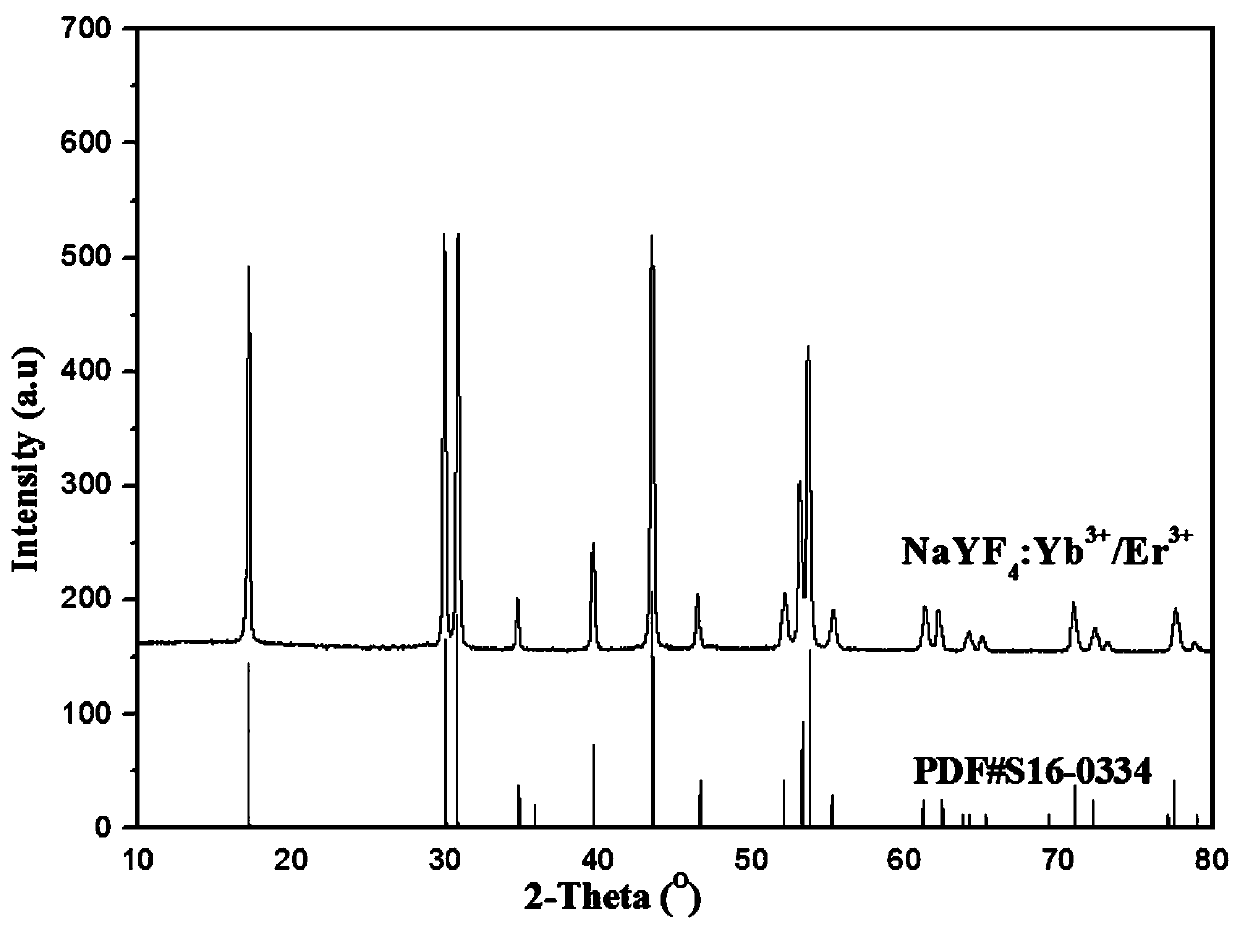

[0044] A method for preparing a hexagonal phase rare earth tetrafluoride sodium salt material by fluorination of low-temperature molten salt, comprising the following steps:

[0045] (1) Weigh 2mmol Na with an electronic balance 2 CO3 , 1.56 mmol Y 2 o 3 , 0.40mmolYb 2 o 3 , 0.04mmolEr 2 o 3 , pour the weighed medicine into the agate crucible and grind it evenly;

[0046] (2) Then weigh 8mmol NH 4 HF 2 Pour into the grinding in step 1, and grind again until all the medicines are ground evenly to obtain the reaction substance;

[0047] (3) Pour the reaction substance ground in step 2 into a 25ml polytetrafluoroethylene liner, and place it in a water heating tank, seal and tighten the water heating tank, and then put the water heating tank into a blast drying oven , set the reaction temperature to 250 o C, the reaction time is 36h, obtains reaction product;

[0048] (4) After the reaction is over, take out the water heat tank and allow it to cool down to room temperat...

Embodiment 2

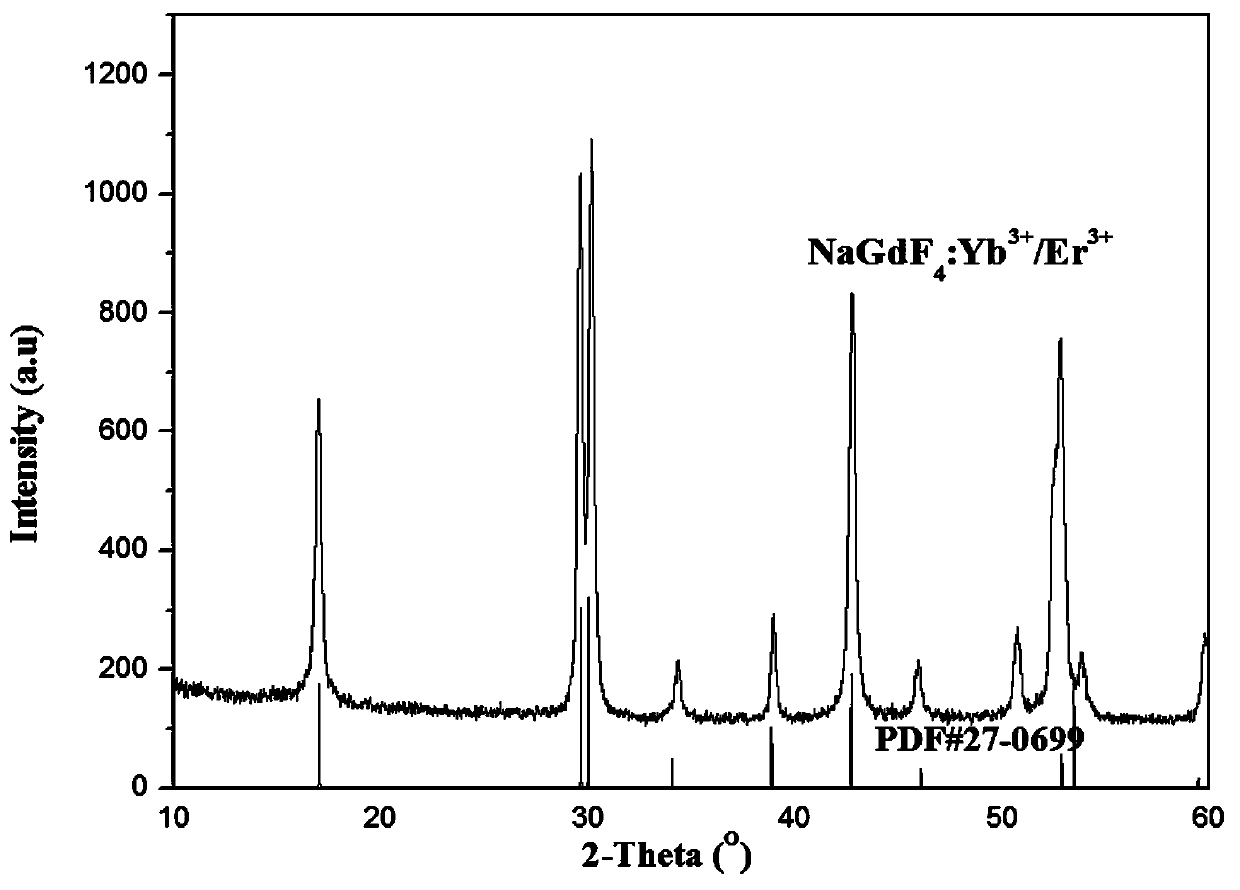

[0051] A method for preparing a hexagonal phase rare earth tetrafluoride sodium salt material by fluorination of low-temperature molten salt, comprising the following steps:

[0052] (1) Weigh 2mmol Na with an electronic balance 2 CO 3 , 1.56 mmol Gd 2 o 3 , 0.40mmolYb 2 o 3 , 0.04mmolEr 2 o 3 , pour the weighed medicine into the agate crucible and grind it evenly;

[0053] (2) Then weigh 8mmol NH 4 HF 2 Pour into the grinding in step 1, and grind again until all the medicines are ground evenly to obtain the reaction substance;

[0054] (3) Pour the medicine that has been ground in step 2 into a 25ml polytetrafluoroethylene liner, and place it in a water heating tank, seal and tighten the water heating tank, then put the water heating tank into a blast drying oven, Set the reaction temperature to 270 o C, the reaction time is 36h, obtains reaction product;

[0055] (4) After the reaction is over, take out the water heat tank and allow it to cool down to room temper...

Embodiment 3

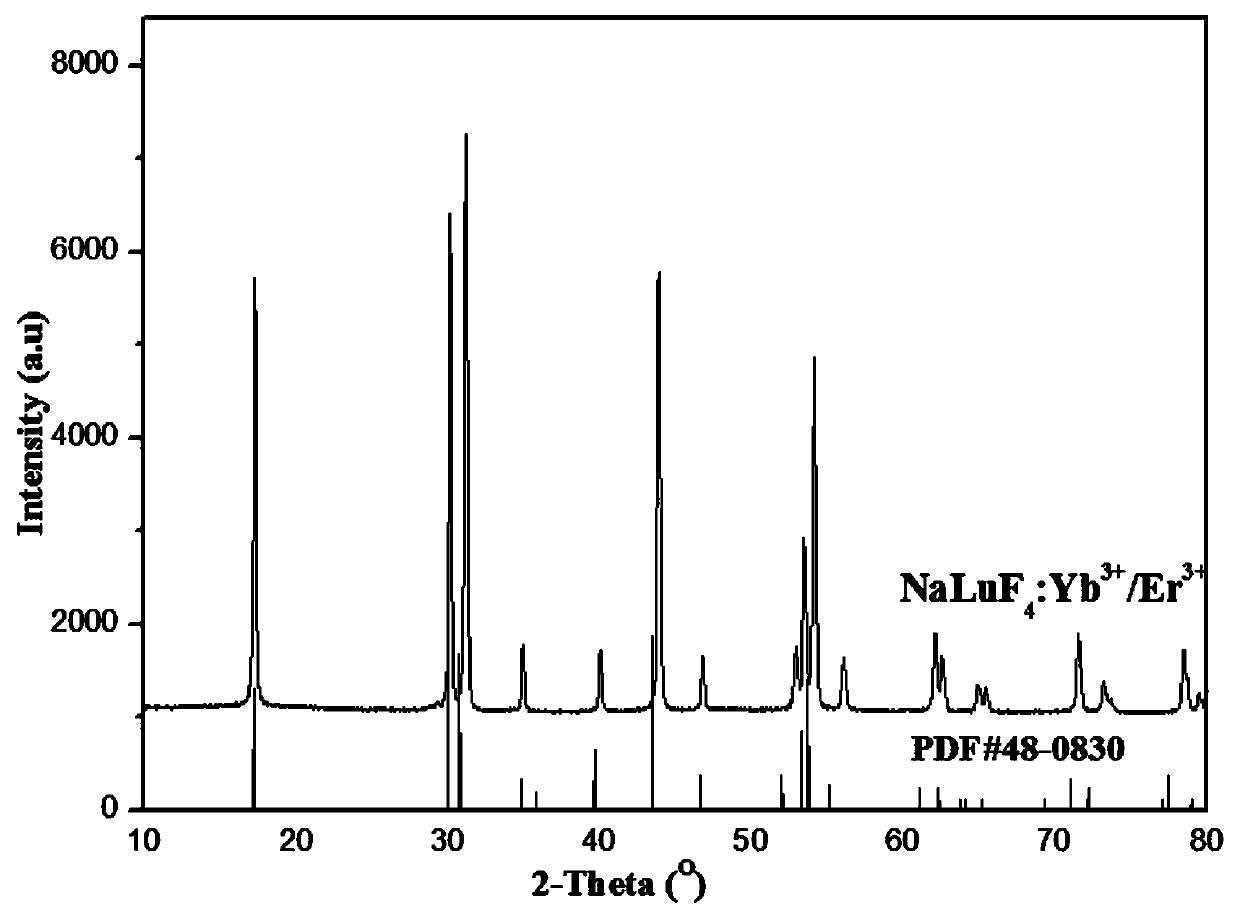

[0058] A method for preparing a hexagonal phase rare earth tetrafluoride sodium salt material by fluorination of low-temperature molten salt, comprising the following steps:

[0059] (1) Weigh 2mmol Na with an electronic balance 2 CO 3 , 1.56 mmol Lu 2 o 3 , 0.40mmolYb 2 o 3 , 0.04mmolEr 2 o 3 , pour the weighed medicine into the agate crucible and grind it evenly;

[0060] (2) Then weigh 8mmol NH 4 HF 2 Pour into the grinding in step 1, and grind again until all the medicines are ground evenly to obtain the reaction substance;

[0061] (3) Pour the reaction substance ground in step 2 into a 25ml polytetrafluoroethylene liner, and place it in a water heating tank, seal and tighten the water heating tank, and then put the water heating tank into a blast drying oven , set the reaction temperature to 270 o C, the reaction time is 36h, obtains reaction product;

[0062] (4) After the reaction is over, take out the water heating tank and allow it to cool down to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com