Device for refining RO concentrated water into crystal mush to realize zero discharge of wet desulphurization wastewater

A wet desulfurization, zero-emission technology, applied in solution crystallization, crystallization separation, separation methods, etc., can solve problems such as increased processing difficulty, precipitation sticking, excessive mother liquor, etc., achieves easy control of crystallization conditions, accelerated steam condensation, The effect of stable crystallization conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

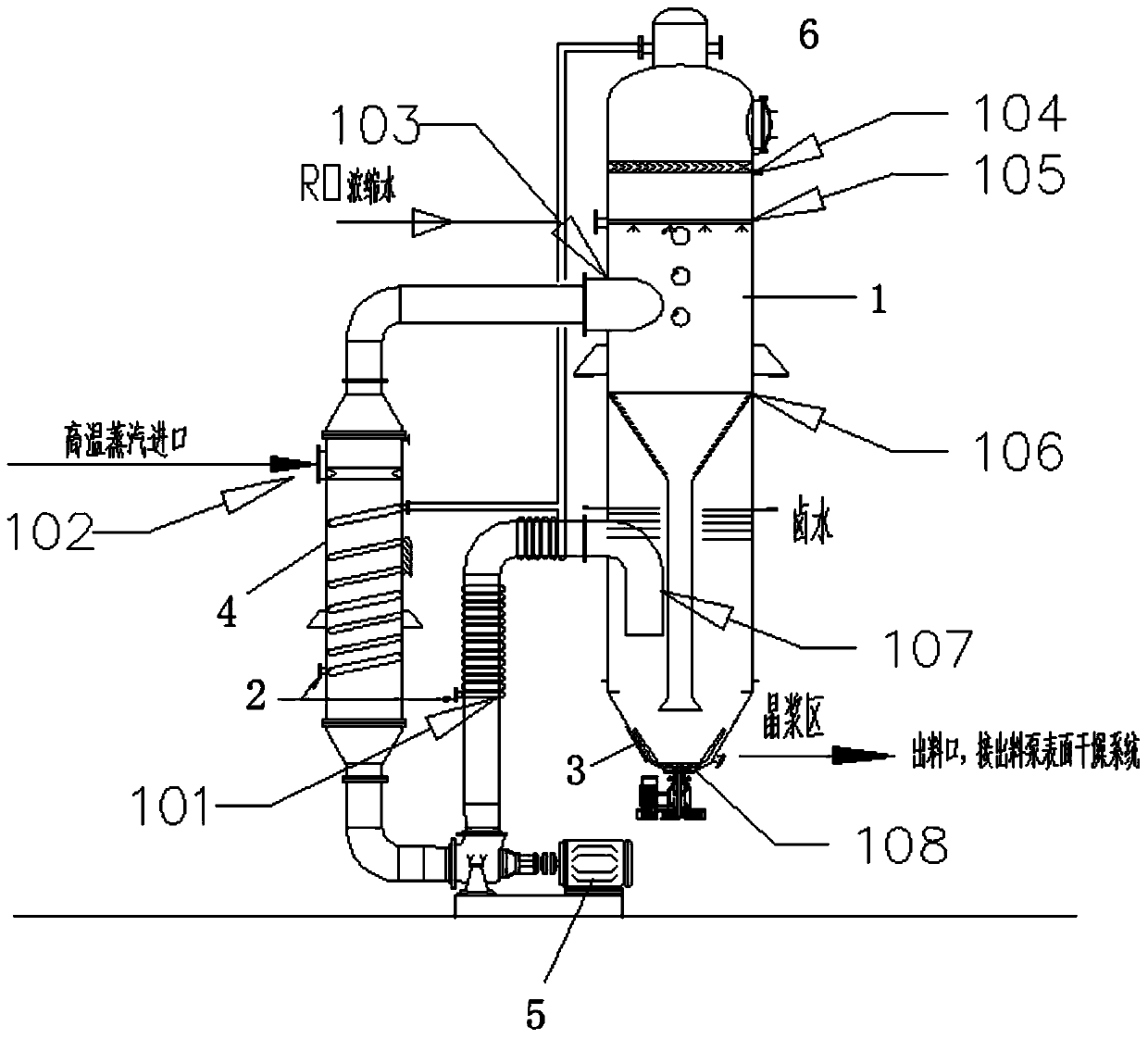

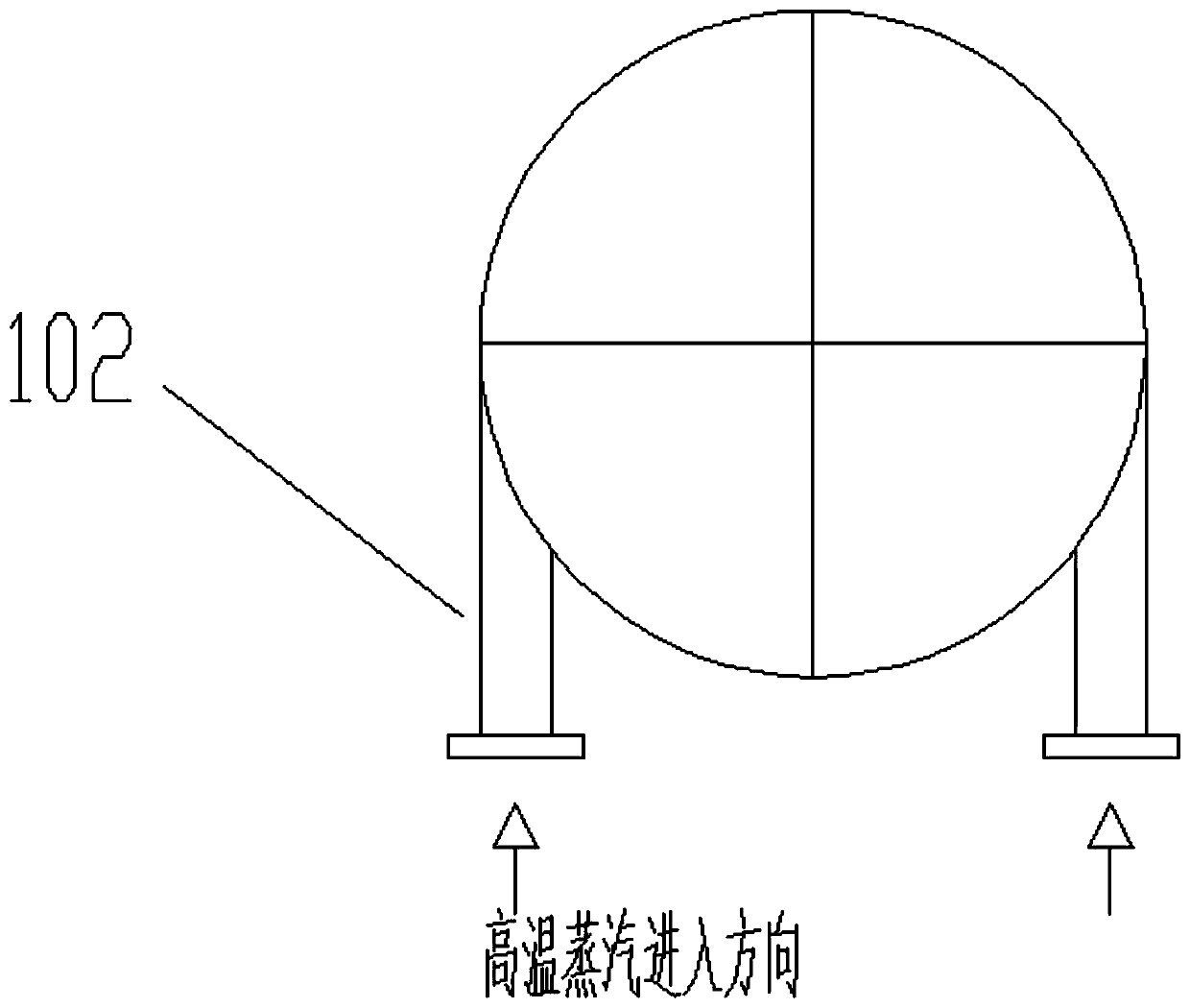

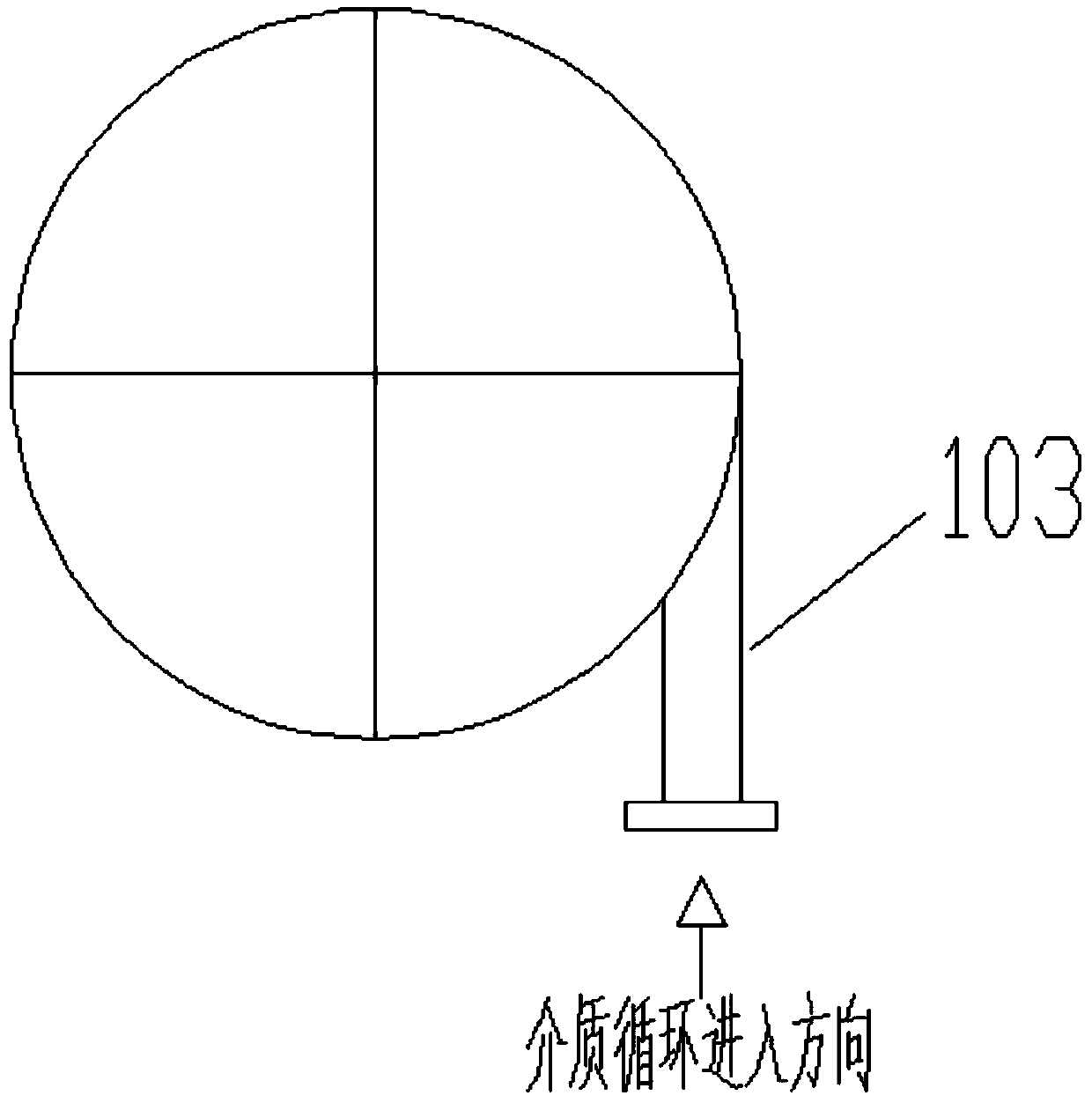

[0034] see Figure 1-Figure 4 , a device for purifying and refining crystal slurry with zero-discharge waste salt from desulfurization wastewater, including a heating cylinder 4 and a separation cylinder 1, the upper part of the separation cylinder 1 is a separation chamber, including a grid separator 104, and an atomizing spray layer 105 . The separation cylinder 1 is provided with a threaded Chen-type Venturi tube, the lower part is a brine area, and the upper side of the brine area is provided with a sunken suction pipe 107 with the nozzle facing downward, and a forced circulation axial flow pump is externally connected. The steam is discharged through the outlet at the top of the separation cylinder container.

[0035] see figure 1 , the hot RO concentrated liquid enters the separation cylinder 1 through the atomization spray layer 105 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com