Ammonium ion permselective nanofiltration membrane, preparation method, application of ammonium ion permselective nanofiltration membrane in sewage ammonium removal and selective ammonium removal device

A selective, ammonium ion technology, applied in the field of nanofiltration membranes, can solve problems such as low separation efficiency, high performance requirements, and osmotic balance limitations, and achieve the effects of improving efficiency, reducing energy consumption, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

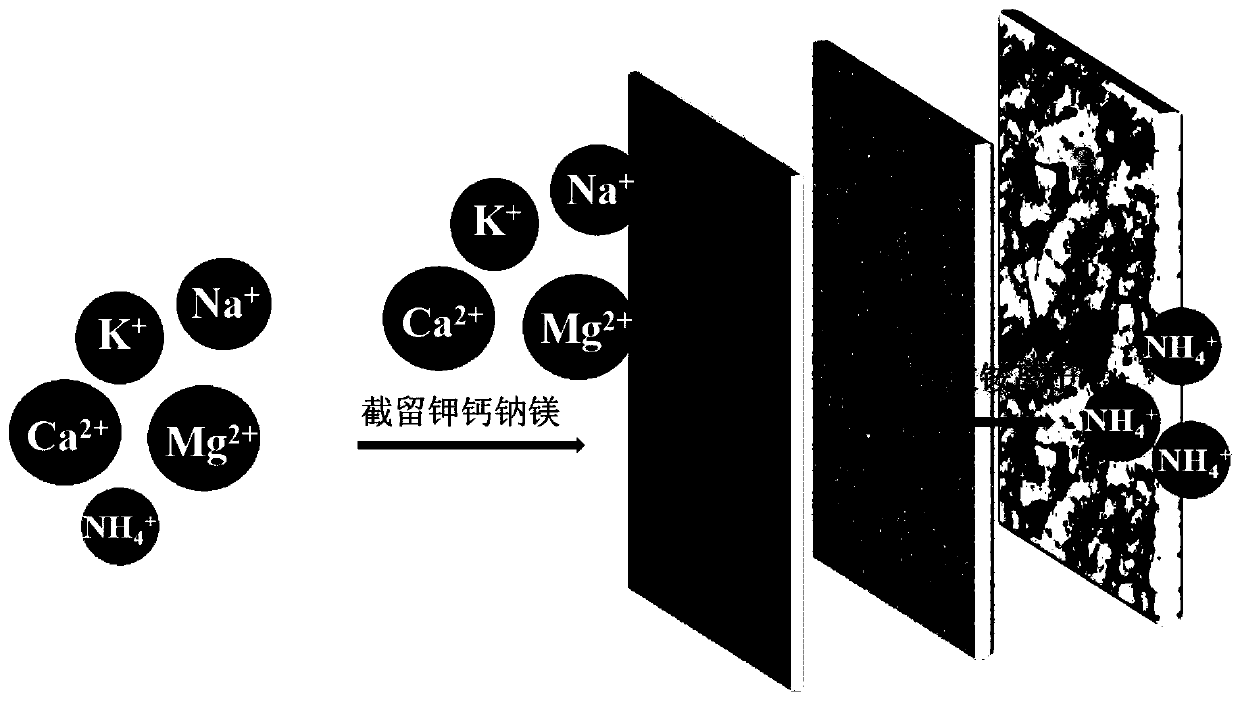

[0046] Embodiment 1 of the present invention provides an ammonium ion selectively permeable nanofiltration membrane, comprising a desalination layer, a basement membrane layer, and a support layer arranged in sequence, and the basement membrane layer contains ammonium ion selective recognition receptors; the ammonium ion The ion-selective recognition acceptor is tripyrazole substituted benzene, and its molecular structure formula is as follows:

[0047]

[0048] From the above structural formula, the tripyrazole substituted benzene selectively recognizes ammonium ions based on three imine nitrogen atoms (N2, N4 and N6) and NH 4 + The subtle interaction of the three pyrazole substituted benzene in specific angles and directions with NH 4 + Hydrogen bonding in N R ···N A approx. N R ···N A ···N R The angle is about 110° (where N R Represents the imine nitrogen atom, N A for NH 4 + Nitrogen atom). This interaction on NH 4 + Perfect for (NH 4 + Consists of fou...

Embodiment 2

[0052] Embodiment 2 of the present invention provides an ammonium ion selectively permeable nanofiltration membrane, which is prepared through the following process steps.

[0053] (1) Preparation of 1,3,5-tris(bromomethyl)-2,4,6-triethylbenzene: To 200mL HBr / AcOH (33wt%) paraformaldehyde (33.4g) and 1,3, Add zinc bromide (39.4g) slowly to a mixture of 5-triethylbenzene (20mL), heat the mixture to 90°C in a water bath, and react for 18h to form white crystals. After the reaction, the mixed solution is cooled to room temperature, and the Water was filtered and washed 3-5 times, and finally the washed white crystals were placed in a vacuum oven and dried at 60°C for 48 hours to obtain a white solid which was 1,3,5-tris(bromomethyl)-2,4,6 - Triethylbenzene.

[0054] (2) Preparation of ammonium ion-selective recognition receptors: Add a small amount of 3,5-dimethylpyrazole (2.92 g) to 80 mL of anhydrous tetrahydrofuran (THF) containing NaH (1.24 g) at room temperature, and dissol...

Embodiment 3

[0058] In order to verify the selective permeation effect of ammonium ions through the nanofiltration membrane to the ammonia nitrogen of the water body, the embodiment 3 of the present invention carried out the dynamic circulation deammonization test and the static Deammonization experiment. details as follows:

[0059] Experiment 1: Dynamic cycle deammonization test.

[0060] Such as Figure 5 As shown, the selective dynamic deammonization experiment is carried out by means of cross-flow filtration. The device used is a membrane stage, which consists of two plexiglass plates to form the first support plate 4 and the second support plate 5. There are holes drilled around the support plate. Eight screw holes 6, a rectangular groove 7 of a certain size is left in the middle of the two support plates, the size is 20cm×0.1cm×7cm, and the first support plate 4 is drilled with a water inlet 8 and a water production port 9, which are respectively used for connecting The water inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com