Fair-faced concrete and its preparation process

A technology of fair-faced concrete and cement, applied in the field of concrete, can solve the problems of increased water absorption rate of recycled aggregates, influence of clear-water concrete compressive strength, and influence on the service life of clear-water concrete, so as to improve compactness and increase apparent density , Improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

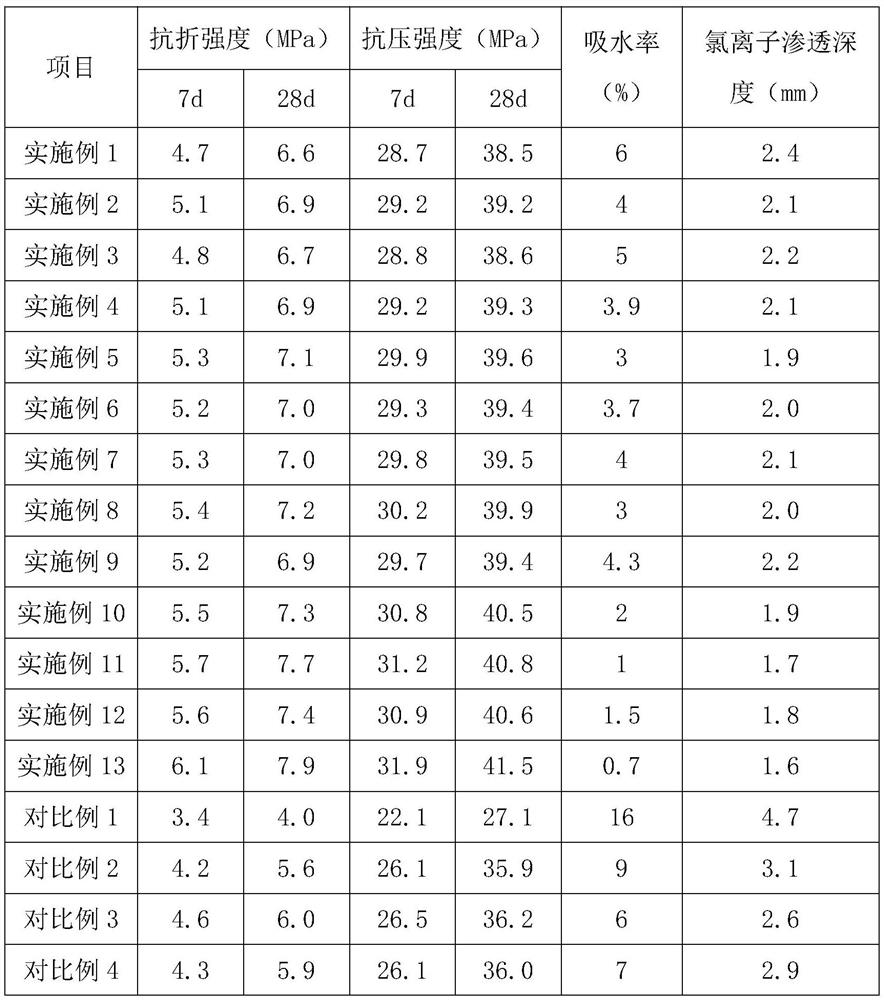

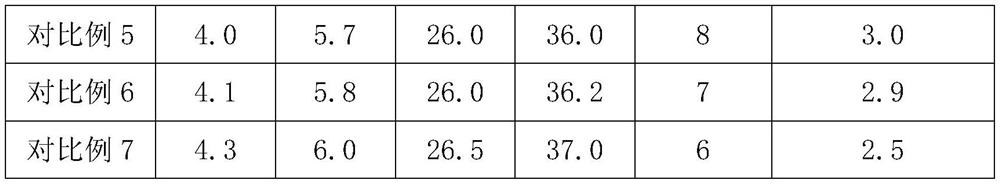

Examples

Embodiment 1

[0062] A kind of fair-faced concrete, by weight, comprises 180 parts of cement, 110 parts of water, 960 parts of recycled coarse aggregate, 480 parts of natural sand, 50 parts of fly ash, 95 parts of mineral powder, 50 parts of glass powder, calcium oxide 30 parts, 3 parts of water-reducing agent, 2 parts of air-entraining agent; The preparation method of above-mentioned fair-faced concrete comprises the steps:

[0063] (1) The preparation method of modified recycled coarse aggregate comprises the steps:

[0064] S1: Take waste concrete, crush it, and sieve it to obtain recycled coarse aggregate with a particle size of 5-25mm;

[0065] S2: Soak the regenerated coarse aggregate in step S1 in a citric acid solution with a mass concentration of 4% for 1 hour, and then dry it;

[0066] S3: In parts by weight, mix 50 parts of polyvinyl alcohol, 20 parts of sodium silicate and 500 parts of water, and then fully stir to obtain a modified solution, which is set aside;

[0067] S4: s...

Embodiment 2

[0072] A kind of fair-faced concrete, by weight, contains 255 parts of cement, 135 parts of water, 1055 parts of recycled coarse aggregate, 555 parts of natural sand, 77.5 parts of fly ash, 107.5 parts of mineral powder, 95 parts of glass powder, calcium oxide 45 parts, 5 parts of water reducing agent, 3.5 parts of air-entraining agent;

[0073] The preparation method of above-mentioned fair-faced concrete comprises the steps:

[0074] (1) The preparation method of modified recycled coarse aggregate comprises the steps:

[0075] S1: Take waste concrete, crush it, and sieve it to obtain recycled coarse aggregate with a particle size of 5-25mm;

[0076] S2: soak the regenerated coarse aggregate in step S1 in a citric acid solution with a mass concentration of 5% for 1.5 hours, and then dry it;

[0077] S3: In parts by weight, mix 60 parts of polyvinyl alcohol, 40 parts of sodium silicate and 600 parts of water and then fully stir to obtain a modified solution, which is set asi...

Embodiment 3

[0083] A kind of fair-faced concrete, by weight, contains 330 parts of cement, 160 parts of water, 1150 parts of recycled coarse aggregate, 630 parts of natural sand, 105 parts of fly ash, 120 parts of mineral powder, 140 parts of glass powder, calcium oxide 60 parts, 7 parts of water reducing agent, 5 parts of air-entraining agent;

[0084] The preparation method of above-mentioned fair-faced concrete comprises the steps:

[0085] (1) The preparation method of modified recycled coarse aggregate comprises the steps:

[0086] S1: Take waste concrete, crush it, and sieve it to obtain recycled coarse aggregate with a particle size of 5-25mm;

[0087] S2: soak the regenerated coarse aggregate in step S1 in a citric acid solution with a mass concentration of 6% for 2 hours, and then dry it;

[0088] S3: In parts by weight, mix 70 parts of polyvinyl alcohol, 60 parts of sodium silicate and 700 parts of water and then fully stir to obtain a modified solution, which is set aside;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com