Preparation method and application of a high-toughness straw fiber-based grass-suppressing mulch film

A technology of straw fiber and high toughness, which is applied in the direction of non-fibrous pulp addition, fiber raw material treatment, cellulose pulp post-treatment modification, etc. It can solve the problems of poor gas barrier property, low weed suppression effect, and low folding resistance, and achieves Good water retention, prevention of soil moisture evaporation, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Preparation of Fermented Straw Fiber by High Temperature Pretreatment

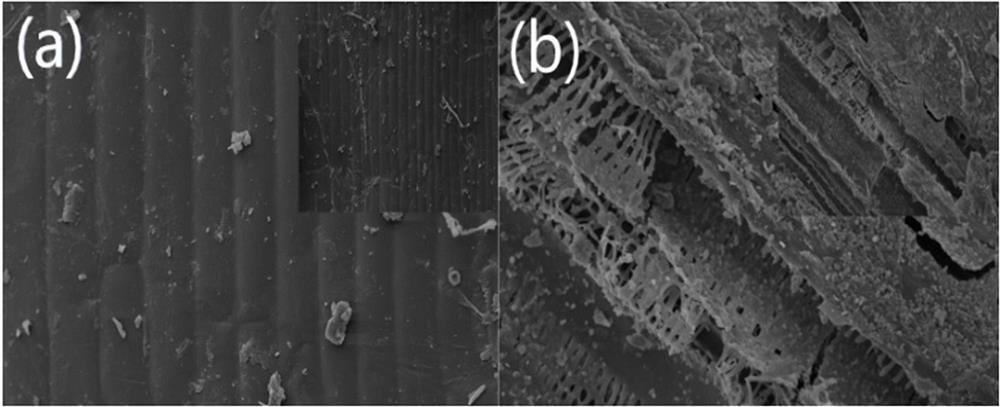

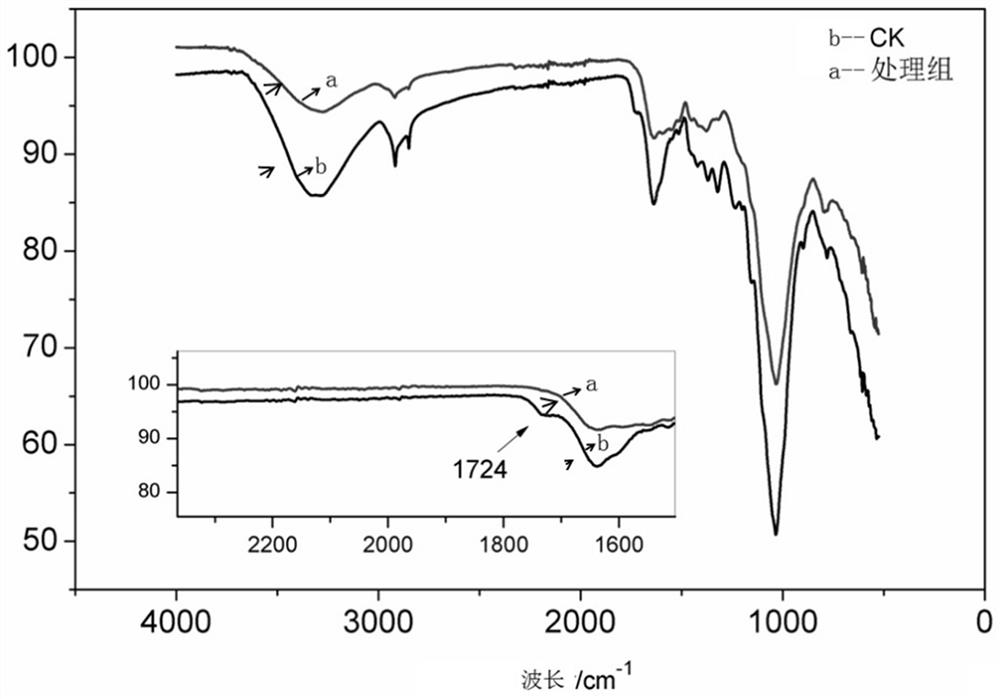

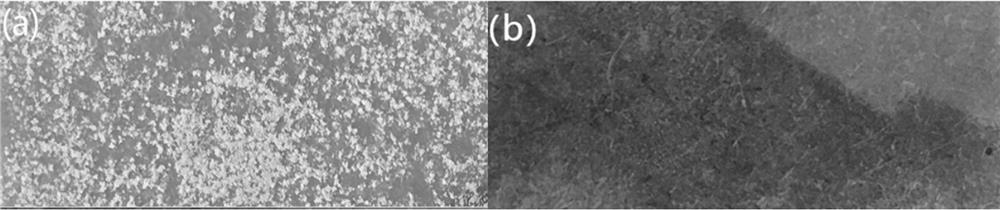

[0054] S1: Take 1.6kg of rice straw (1-2cm) that has been crushed and sieved to remove fine components, add 14.5g of urea, and a microbial agent with a mass fraction of 5%, and adjust the carbon-nitrogen ratio of the system to 30:1, and the moisture content to 65%. After the materials are mixed evenly, they are transferred to a fermentation reactor, and the fermentation materials are placed in an incubator at 60° C. for 12 days to ferment. During the fermentation process, the piles were turned every 3 days to provide fresh air naturally (treatment group). At the same time, those who were not inoculated with microbial agents were coded CK as the control group. After high-temperature (60-65°C) fermentation pretreatment, the split straw fiber is obtained, and its scanning electron microscope picture is as follows figure 1 As shown, the Fourier transform infrared spectrum is shown as figur...

Embodiment 2

[0059] Example 2: Preparation of high-toughness straw fiber-based grass-suppressing mulch

[0060] S1: High-temperature pretreatment to prepare fermented straw fibers, the specific steps are the same as in Example 1;

[0061] S2: Mix 300g of fermented straw fibers obtained in step S1 with 30g of polyvinyl formal fibers, and mechanically pulp using beating equipment, with a beating concentration of 1.57% and a beating degree of 55°SR. Add 15g of organic montmorillonite, 6g of polyamide epichlorohydrin as a wet strength agent, 4.5g of cationic dispersing rosin gum, and 2.7g of aluminum sulfate as a retention aid, stir the slurry evenly, and form a straw fiber base film through a molding machine. The number is MF-1, spare.

[0062] S3: 4g of chitosan dissolved in 100g of 1% acetic acid solution was placed in a magnetic stirrer and stirred for 2 hours to obtain a mixed solution; 1g of nanocellulose and 0.5g of glycerin were added to the mixed solution, and the magnetic Stir unde...

Embodiment 3

[0066] Example 3 Preparation of High Tenacity Straw Fiber Base Membrane (Comparative Example)

[0067] S1: High-temperature pretreatment to prepare fermented straw fibers, the specific steps are the same as in Example 1;

[0068] S2: Preparation of straw fiber base film

[0069] 300 g of fermented straw fibers obtained in step S1 were subjected to mechanical pulping with a beating concentration of 1.57% and a beating degree of 55°SR. Add 9g of organic montmorillonite, 4.5g of wet strength agent polyamide epichlorohydrin, 6g of cationic dispersing rosin gum, and 0.5g of retention aid aluminum sulfate, stir the slurry evenly, and form a straw fiber base film through a molding machine. Numbered MF-4, spare.

[0070]S3: Preparation of high-toughness straw fiber-based grass-suppressing mulch film

[0071] The specific steps for preparing the modified nanocellulose / chitosan polymerization solution are the same as step S3 in Example 2, but no hydrolyzed soybean protein isolate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com