Water-insoluble fiber powder manufacturing method and finished product thereof

A manufacturing method and technology of fiber powder, which is applied in the manufacture of water-insoluble fiber powder and its finished products, can solve the problems of rough finished products and difficulty in controlling the particle size of fiber powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

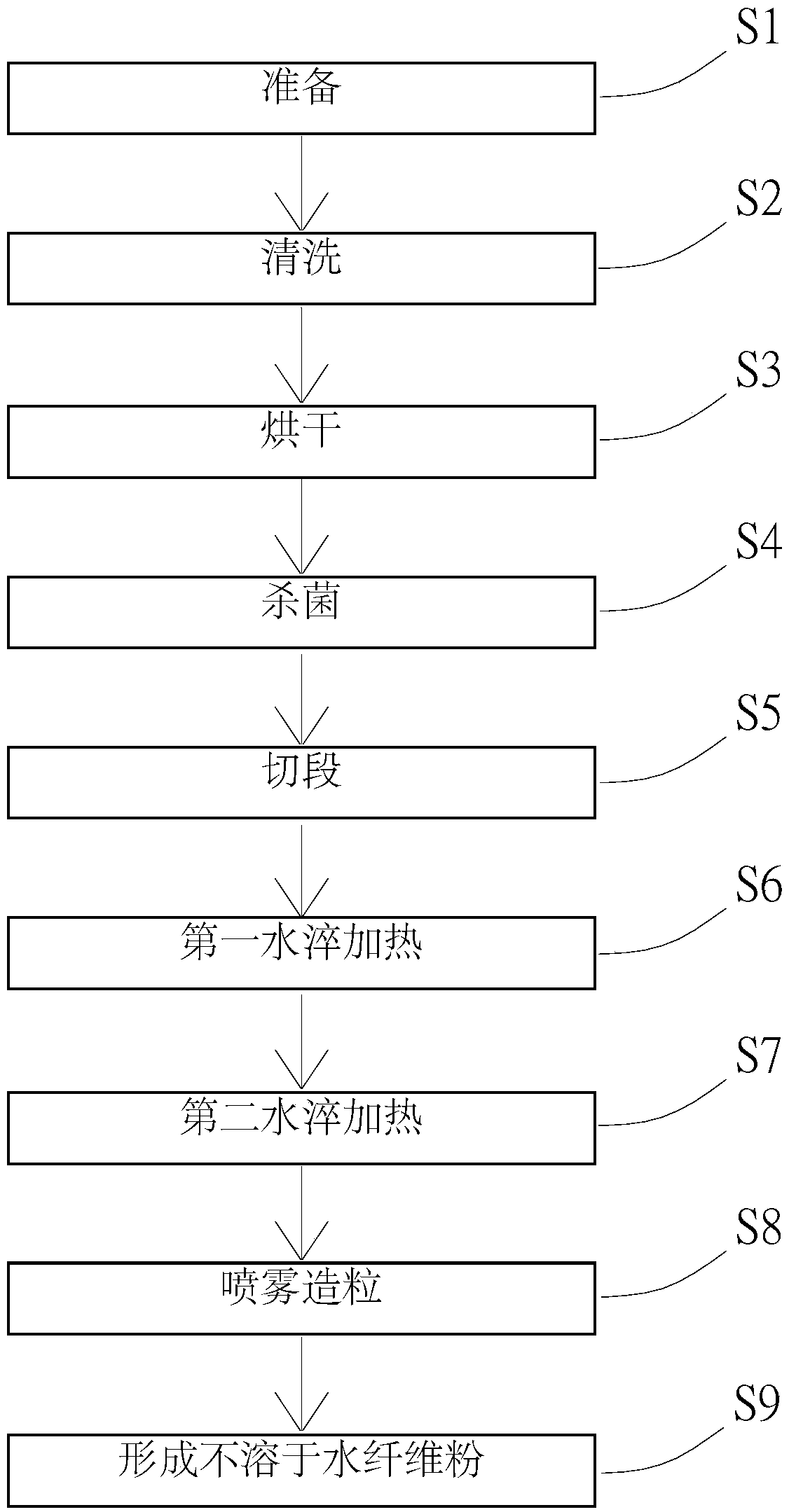

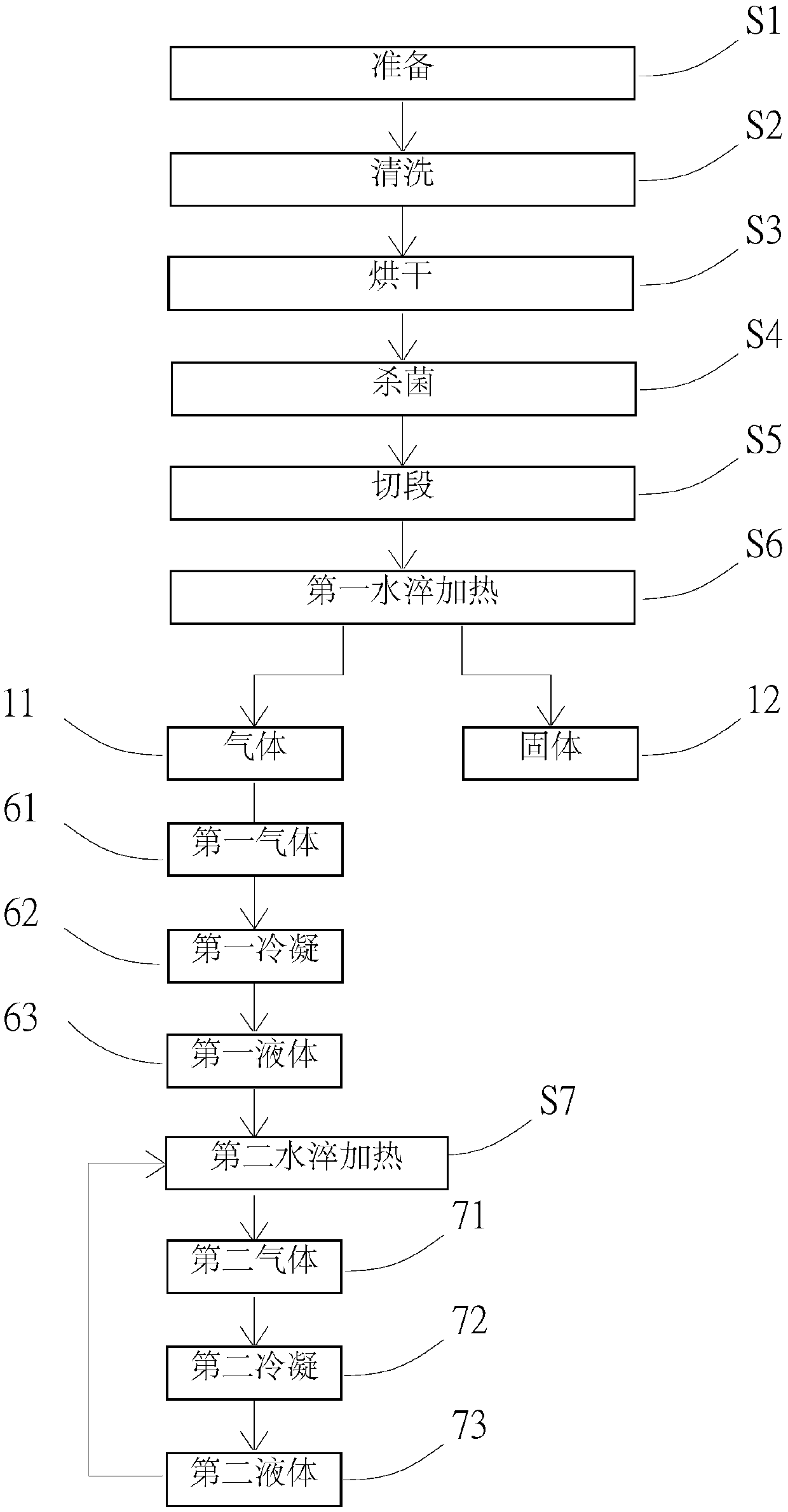

[0070] see Figures 1 to 10 , is a preferred embodiment of the manufacturing method of the water-insoluble fiber powder of the present invention, at least including the following steps.

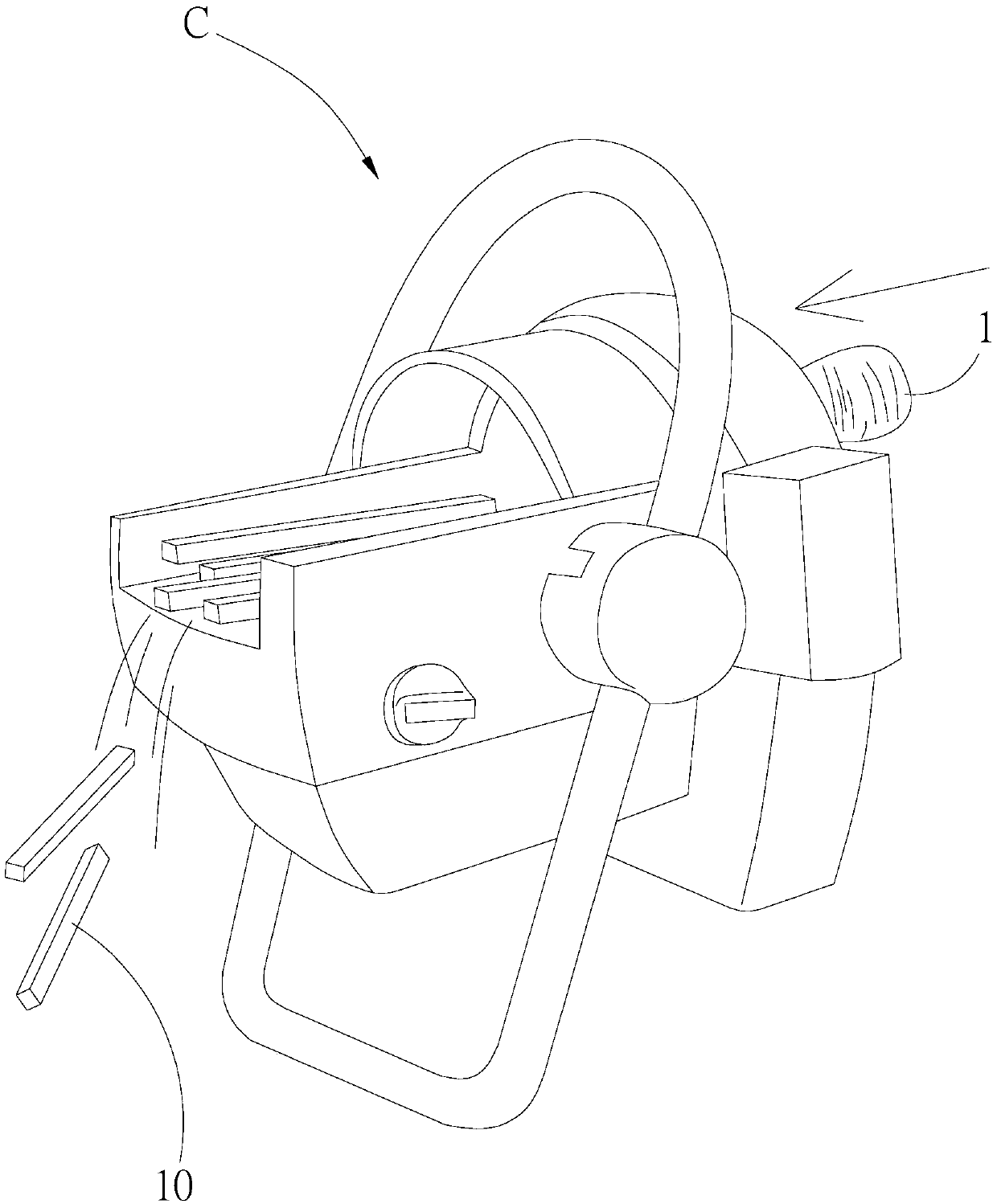

[0071] Preparation step S1: prepare the mixture 1 of pine and eucalyptus; wherein the mixture 1 mainly removes parts such as bark and trees from pine and eucalyptus, and mixes them to form mixture 1; and the pine bark of pine Contains a variety of unknown powerful antioxidant substances, pinenol is a powerful antioxidant substance extracted from carefully selected radiata pine (Pinus Radiata) bark. In addition to containing a variety of flavonoids, pine alcohol can also improve the physiological activity of vitamin C and E. As an antioxidant substance, it can protect human blood vessels, protect cells from skin damage (aging), various inflammations and other activities Oxygen and other damage; among them, the eucalyptus has the advantages of relieving hot symptoms, relieving colds, relieving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com