Integrated device and technology for liquid phase flue gas desulfurization and denitration method

A technology of desulfurization and denitrification and liquid phase method, which is applied in the field of integrated device for simultaneous desulfurization and denitrification of flue gas by liquid phase method, can solve the problems of difficult removal of nitrogen oxides, high temperature denitrification energy consumption, etc., and achieve the improvement of absorption reaction rate and no Effects of secondary pollution and improvement of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

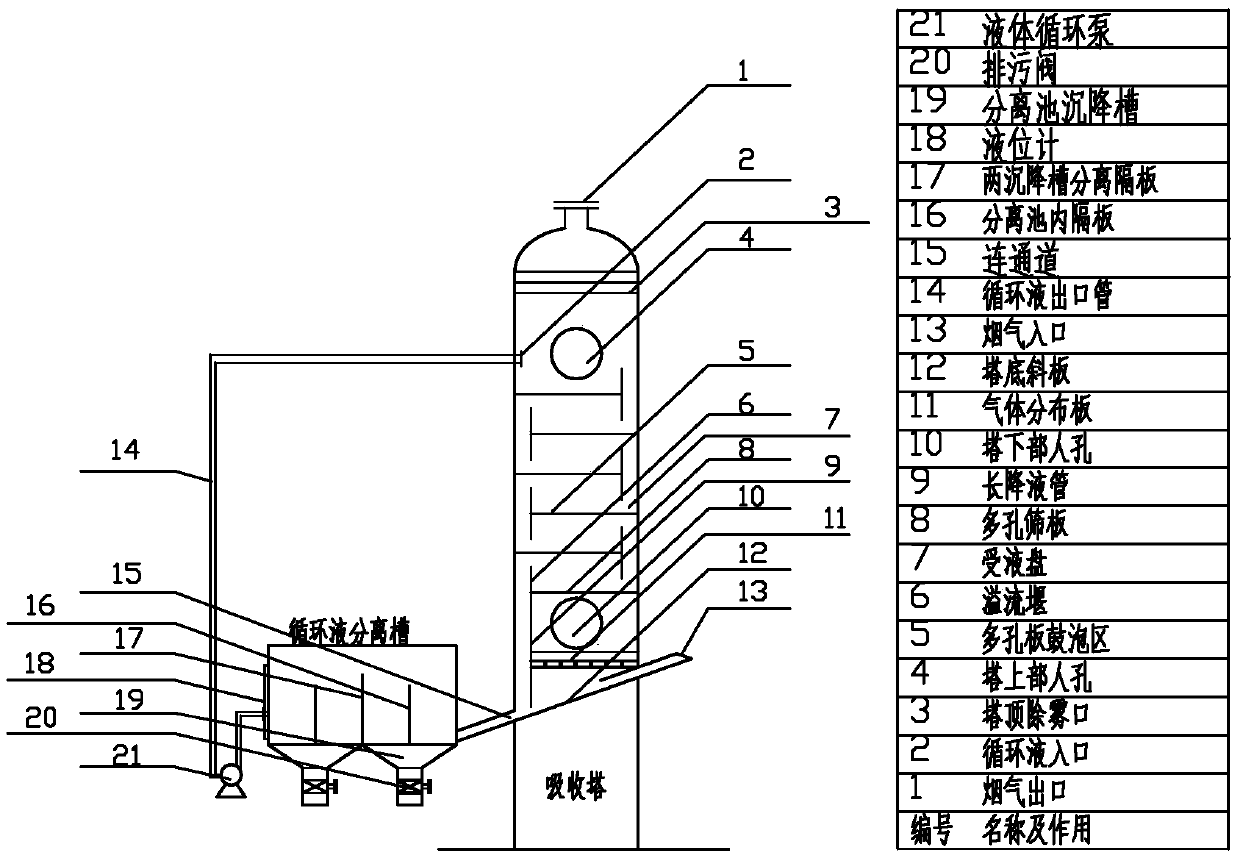

[0043] in such as figure 1 In the above-mentioned amplified integrated device system shown above, four porous sieve plates (8) and one gas distribution plate (11) are arranged in the absorption tower, the flow rate of the absorption liquid circulation pump (21) is 10m3 / h, and the flow rate of the induced draft fan is Fully open; sodium chlorite / sodium carbonate is used as absorbent, the total concentration is 0.15mol / L, that is, 36kg of 80% sodium chlorite and 9kg of sodium carbonate are added. Operate in an environment of 8-15 degrees Celsius and normal pressure. The measured flue gas concentration before treatment is: sulfur dioxide content is 415ppm, nitrogen monoxide content is 1419ppm, and nitrogen dioxide is 71ppm; after treatment, the content of flue gas is: sulfur dioxide 6ppm, nitrogen monoxide 50ppm, nitrogen dioxide 3ppm, remove The rates are respectively 98.6% for sulfur dioxide and 96.4% for nitrogen oxides.

Embodiment 2

[0045] in such as figure 1 In the system of the amplifying integrated device shown above, four porous sieve plates (8) and one gas distribution plate (11) are installed inside, and the flow rate of the absorption liquid circulation pump (21) is 13m 3 / h, the flow rate of the induced draft fan is three-quarters of the opening; 0.075mol / L sodium hypochlorite and 0.075mol / L potassium permanganate were added respectively, that is, 70kg of 10% sodium hypochlorite, 31.5kg of potassium permanganate, and hydrogen were added Sodium oxide 2kg. The measured concentrations before absorption are: sulfur dioxide 451ppm, nitrogen monoxide 1488ppm, nitrogen dioxide 74ppm; the concentrations of sulfur dioxide and nitrogen oxides in the flue gas at the outlet are: sulfur dioxide 10ppm, nitrogen monoxide 24ppm, nitrogen dioxide 2ppm; The removal rates of sulfur dioxide and nitrogen oxides were 97.8% and 98.3%, respectively.

Embodiment 3

[0047] in such as figure 1 In the system of the enlarged absorption device shown, six porous sieve plates (8) are arranged in the absorption tower, and a gas distribution plate (11) is installed at the bottom of the tower; absorb 20 kg of 80% sodium chlorite and 50 kg of 27.5% sodium hypochlorite agent, sodium hydroxide 4kg, the total concentration is 0.096mol / L, the flow rate of the absorption liquid circulation pump (21) is 8m3 / h, and the flow rate of the induced draft fan is opened for three-quarters; the concentration before the absorption is measured as: sulfur dioxide 402ppm, one Nitrogen oxide 1375ppm, nitrogen dioxide 69ppm; the concentrations of sulfur dioxide and nitrogen oxides in the flue gas at the outlet are: sulfur dioxide 0ppm, nitrogen monoxide 59ppm, nitrogen dioxide 3ppm; calculated sulfur dioxide removal rate of 100%, nitrogen oxides The total removal rate is 95.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com