Method for improving fluorescence quantum yield of II-VI family quantum dots

A technology of fluorescence quantum yield and quantum dots, which is applied in the field of nanomaterials and inorganic materials, can solve the problems of not affecting the emission wavelength of quantum dots, and achieve the effects of saving experimental operation time, facilitating industrial production, and improving fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

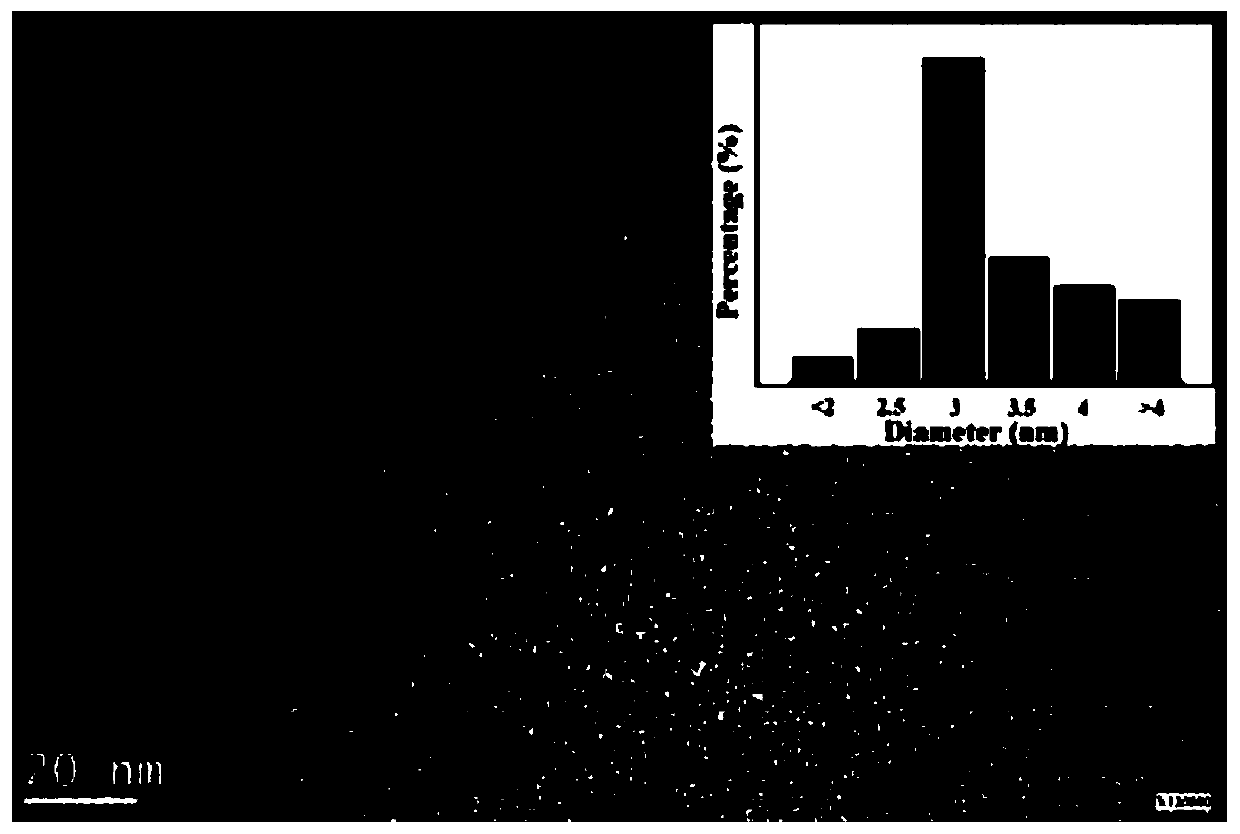

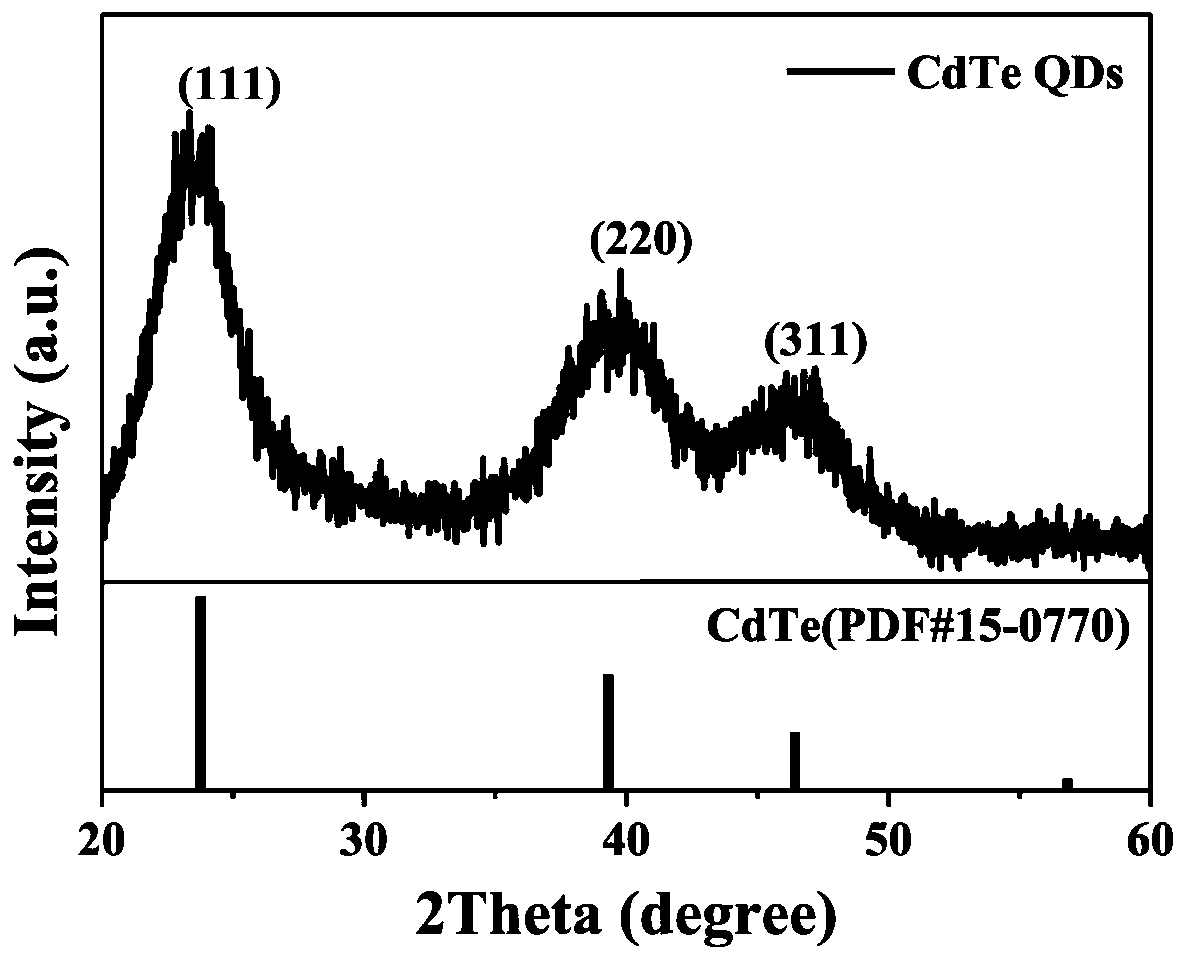

[0039] 1) Put 0.046g of tellurium powder, 0.04g of sodium borohydride and 2ml of deionized water into a three-neck bottle, and stir under a nitrogen atmosphere until the black powder is completely dissolved and becomes a purple or light pink anion precursor;

[0040] 2) Put 0.114g of cadmium chloride, 0.133g of mercaptopropionic acid and 100ml of deionized water into a three-necked bottle, adjust the pH value of the solution to 8.2 with sodium hydroxide solution, and inject nitrogen to obtain a cationic precursor solution;

[0041] 3) Take 400 μl of the anion precursor solution obtained in step 1) with a syringe or a liquid gun and quickly inject it into the cationic precursor solution in step 2), stir and heat to 95°C for condensation and reflux. In reactions 2, 4, 6, and 8 25ml were sampled every hour, cooled to room temperature to obtain cadmium telluride quantum dot solutions with different emission wavelengths;

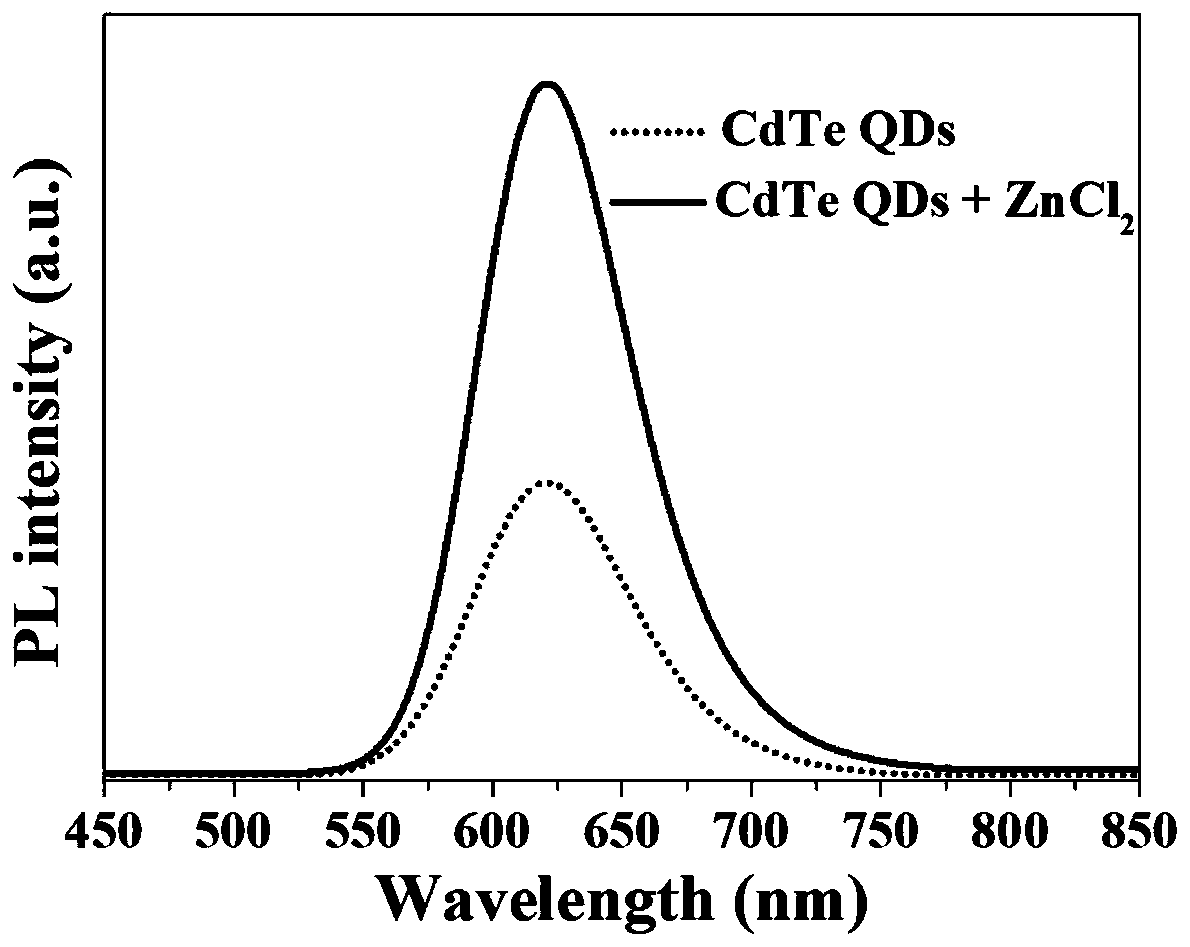

[0042] 4), add 0.05g of zinc chloride to the four 25ml cadm...

Embodiment 2

[0045] 1) Put 0.046g of tellurium powder, 0.04g of sodium borohydride and 2ml of deionized water into a three-neck bottle, and stir under a nitrogen atmosphere until the black powder is completely dissolved and becomes a purple or light pink anion precursor;

[0046] 2) Put 0.114g of cadmium chloride, 0.133g of mercaptopropionic acid and 100ml of deionized water into a three-neck bottle, adjust the pH value of the solution to 8.0 with sodium hydroxide solution, and inject nitrogen gas to obtain a cationic precursor solution;

[0047] 3) Take 400 μl of the anionic precursor solution obtained in step 1) with a syringe or a liquid gun and quickly inject it into the cationic precursor solution in step 2). After stirring for 5 minutes, transfer 25ml of the solution to the reaction kettle and heat After reacting for 1, 2, 3, and 4 hours, cool to room temperature to obtain cadmium telluride quantum dot solutions with different emission wavelengths;

[0048] 4), add 0.03g of zinc chlo...

Embodiment 3

[0051]1) Put 0.046g of tellurium powder, 0.04g of sodium borohydride and 2ml of deionized water into a three-neck bottle, and stir under a nitrogen atmosphere until the black powder is completely dissolved and becomes a purple or light pink anion precursor;

[0052] 2) Put 0.118g of cadmium nitrate, 0.158g of mercaptopropionic acid and 100ml of deionized water into a three-necked bottle, adjust the pH value of the solution to 8.5 with sodium hydroxide solution, and inject nitrogen gas to obtain a cationic precursor solution;

[0053] 3) Take 400 μl of the anion precursor solution obtained in step 1) with a syringe or a liquid gun and quickly inject it into the cationic precursor solution in step 2), stir and heat to 95°C for condensation and reflux. In reactions 2, 4, 6, and 8 Sampling 25ml respectively in hour, is cooled to room temperature, obtains the cadmium telluride quantum dot solution of different emission wavelengths;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com