Photo-thermal sensitive carboxymethyl chitosan nano drug-loaded microsphere and preparation method thereof

A technology of carboxymethyl chitosan and nano-drug loading, which is applied in the field of biomedical materials, can solve the problems of complexity, body stimulation, toxic and side effects, etc., and achieve the effect of increasing the loading rate, increasing the loading rate, and increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

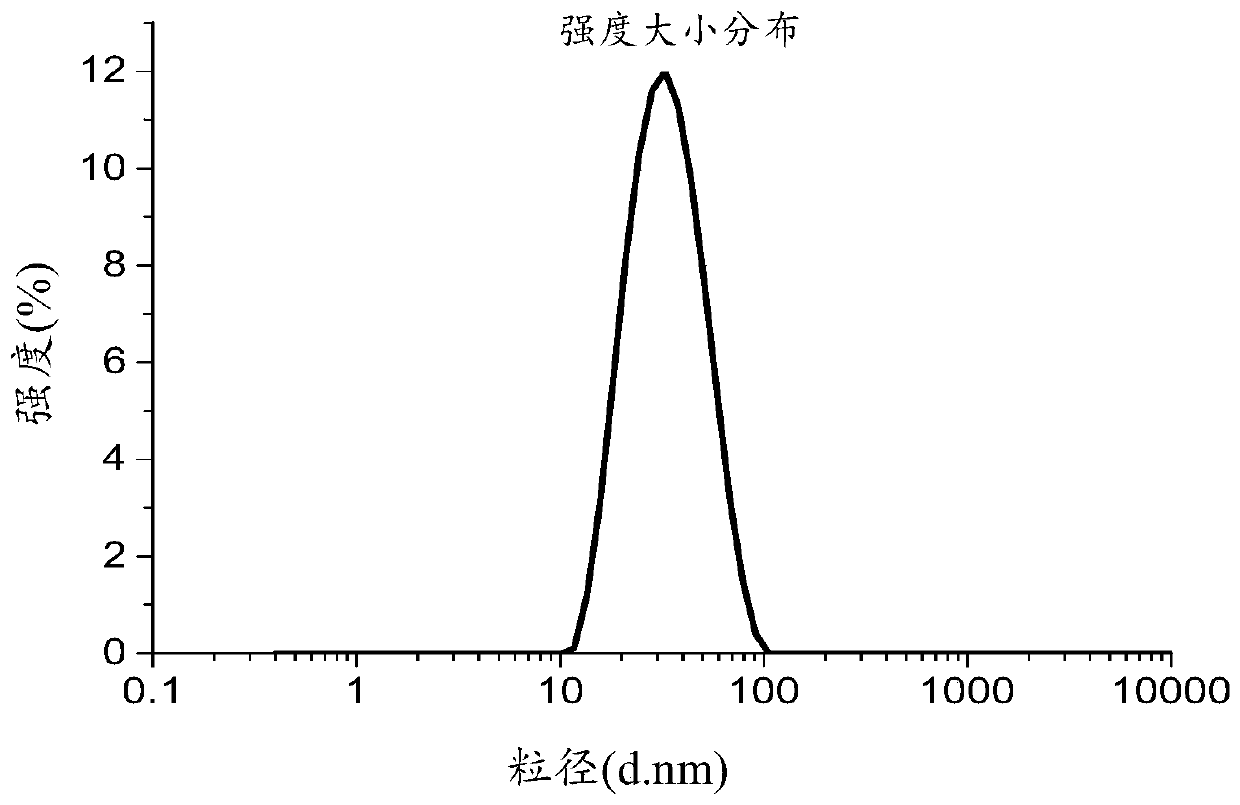

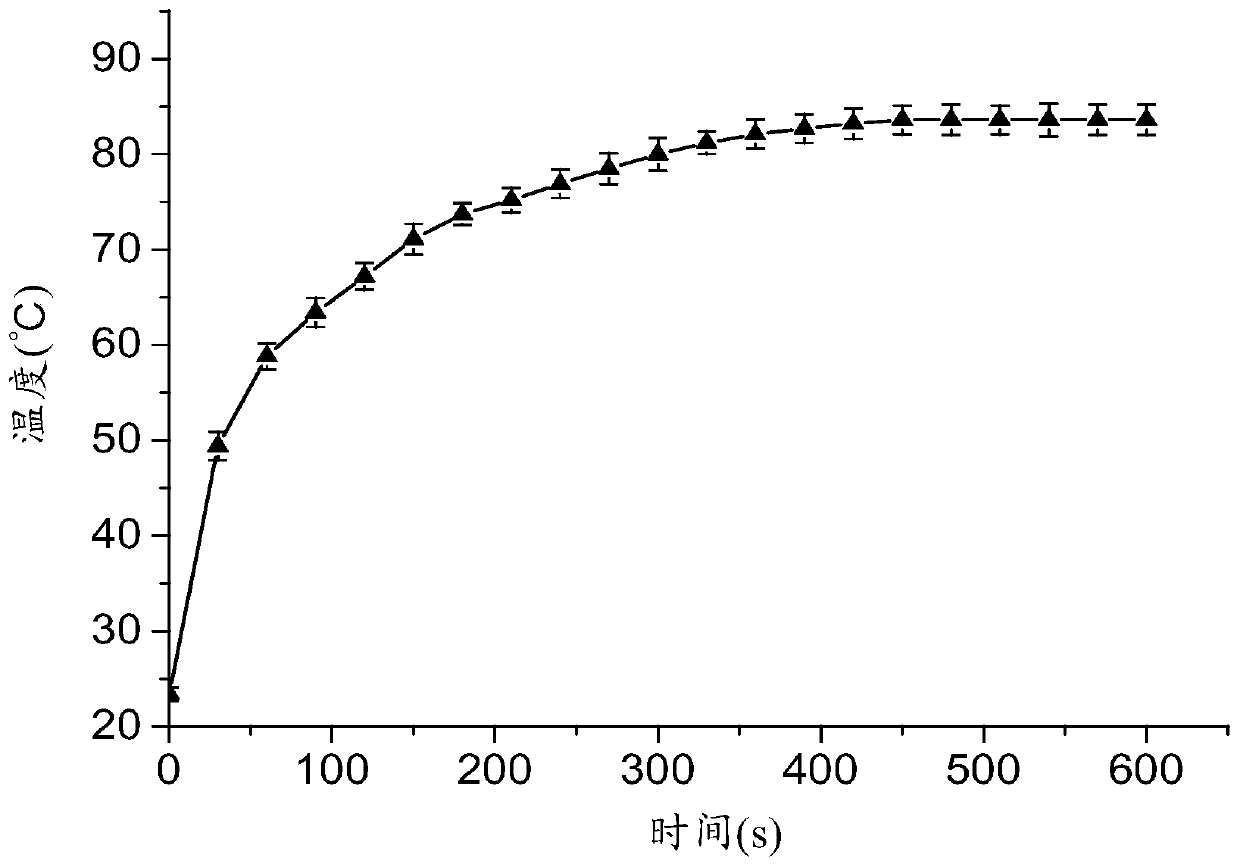

[0040] Embodiment 1 The oil-water ratio is the preparation of photothermally sensitive carboxymethyl chitosan nano drug-loaded microspheres of 10:1 1, the preparation of CMCS-NIPAm copolymer

[0041] Dissolve 0.24g carboxymethyl chitosan and 0.24g N-isopropylacrylamide with a mass ratio of 1:1 in 20mL deionized water, accelerate the dissolution with magnetic stirring, heat to 70°C under nitrogen protection, and slowly add 5mg 2mL of potassium persulfate / mL initiates the polymerization reaction, keeps at 70°C for 3h under nitrogen atmosphere, precipitates with acetone, centrifuges at 10000r / min for 10min, and vacuum-dries at 40°C to obtain carboxymethyl chitosan grafted N-iso Propylacrylamide polymer (CMCS-NIPAm copolymer).

[0042] Carry out Fourier transform infrared characterization to the CMCS-NIPAm copolymer prepared in embodiment 1, scanning result is as follows Figure 4 As shown, the spectral characteristics of CMCS are as follows: 3427cm -1 Telescoping for O-H and N-...

Embodiment 2

[0051] Example 2 The preparation of photothermal-sensitive carboxymethyl chitosan nano drug-loaded microspheres with an oil-water ratio of 20:1 1. Preparation of CMCS-NIPAm copolymer

[0052] Dissolve 0.24g carboxymethyl chitosan and 0.24g N-isopropylacrylamide with a mass ratio of 1:1 in 20mL deionized water, accelerate the dissolution with magnetic stirring, heat to 70°C under nitrogen protection, and slowly add 5mg 2mL of potassium persulfate / mL initiates the polymerization reaction, keeps at 70°C for 3h under nitrogen atmosphere, precipitates with acetone, centrifuges at 10000r / min for 10min, and vacuum-dries at 40°C to obtain carboxymethyl chitosan grafted N-iso Propylacrylamide polymer (CMCS-NIPAm copolymer).

[0053] Similarly, Fourier infrared characterization was performed on the CMCS-NIPAm copolymer prepared in Example 2 to ensure that N-isopropylacrylamide was successfully grafted onto carboxymethyl chitosan.

[0054] 2. Preparation of photothermally sensitive carb...

Embodiment 3

[0060] Example 3 Preparation of photothermally sensitive carboxymethyl chitosan nano drug-loaded microspheres with an oil-water ratio of 30:1

[0061] 1. Preparation of CMCS-NIPAm copolymer

[0062] Dissolve 0.24g carboxymethyl chitosan and 0.24g N-isopropylacrylamide with a mass ratio of 1:1 in 20mL deionized water, accelerate the dissolution with magnetic stirring, heat to 70°C under nitrogen protection, slowly drop 5mg / 2 mL of potassium persulfate was used to initiate the polymerization reaction, kept at 70°C for 3 h under nitrogen atmosphere, precipitated with acetone, centrifuged at 10,000 r / min for 10 min, and dried under vacuum at 40°C to obtain carboxymethyl chitosan grafted with N-isopropyl Based acrylamide polymer (CMCS-NIPAm copolymer).

[0063] Similarly, Fourier transform infrared characterization was performed on the CMCS-NIPAm copolymer prepared in Example 3 to ensure that N-isopropylacrylamide was successfully grafted onto carboxymethyl chitosan.

[0064] 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

| degree of carboxylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com