A dealcoholized transparent silicone sealant with long shelf life

A silicone sealant and dealcoholization technology, applied in the field of sealants, can solve the problems of slow curing, slow hydrolysis, poor compatibility, etc., and achieve the effect of reducing the curing depth, prolonging the surface drying time, and preventing curing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

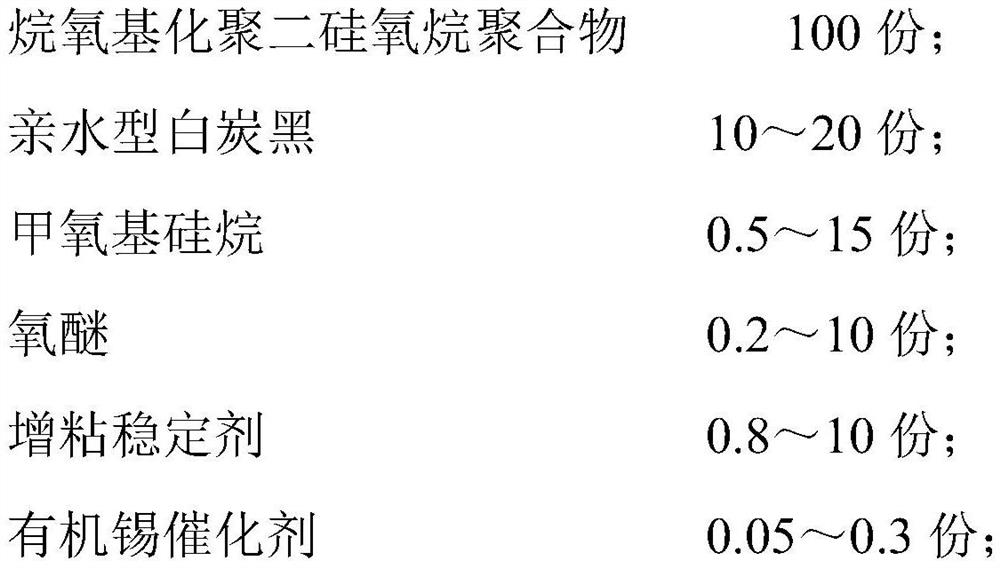

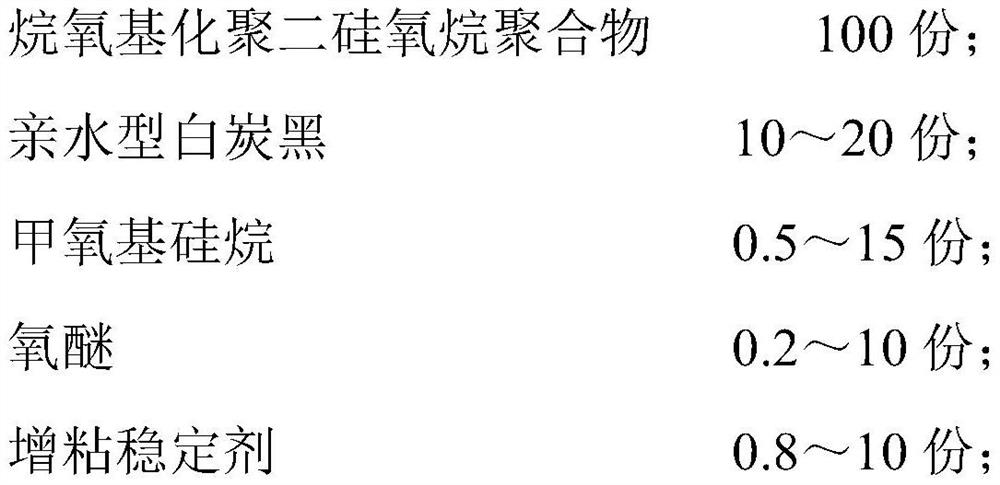

Method used

Image

Examples

Embodiment 1

[0035] Mix 100 parts of methyltrimethoxysilane, 10 parts of water in a transparent airtight container. Shake for one minute, stand still, observe every other day, and a clear interface layer can be seen after one week.

Embodiment 2

[0039] Mix 100 parts of methyltrimethoxysilane, 10 parts of water, and 2 parts of tetramethylguanidine in a transparent open container, shake it for one minute and let it stand, take samples every half hour to analyze the moisture content, after 6 hours the moisture tends to It is stable at 3.5g / l.

Embodiment 3

[0045] Under moisture-proof conditions, add 5 parts of methyltrimethoxysilane, 0.3 parts of ethylene glycol methyl ether, 0.1 part of tetramethylguanidine and 10 parts of simethicone oil with a viscosity of 250 lipoise to 100 parts of simethicone oil with a viscosity of 50000 li Potassium methyltrimethoxysilane-terminated polydimethylsiloxane and mix well, then add hydrophilic white carbon black with a moisture content of 0.3%, and after vacuum stirring for one hour, add 0.8 parts of 3-isocyanate Propyltrimethoxysilane and 0.2 parts of dibutyltin laurate were packaged after defoaming, aged at a temperature of 100°C, and their performance was assessed for 24 hours.

[0046] The results are shown in Table 1, so it can be seen that:

[0047] Table 1 embodiment 3 and the product performance comparison prepared by comparative example 3

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com