Preparation method of L-lysine sulfate and by-products thereof

A technology of lysine sulfate and by-products, applied in the field of lysine production technology, can solve the problems of large environmental pollution and high production cost, and achieve the effects of short process route, low cost and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

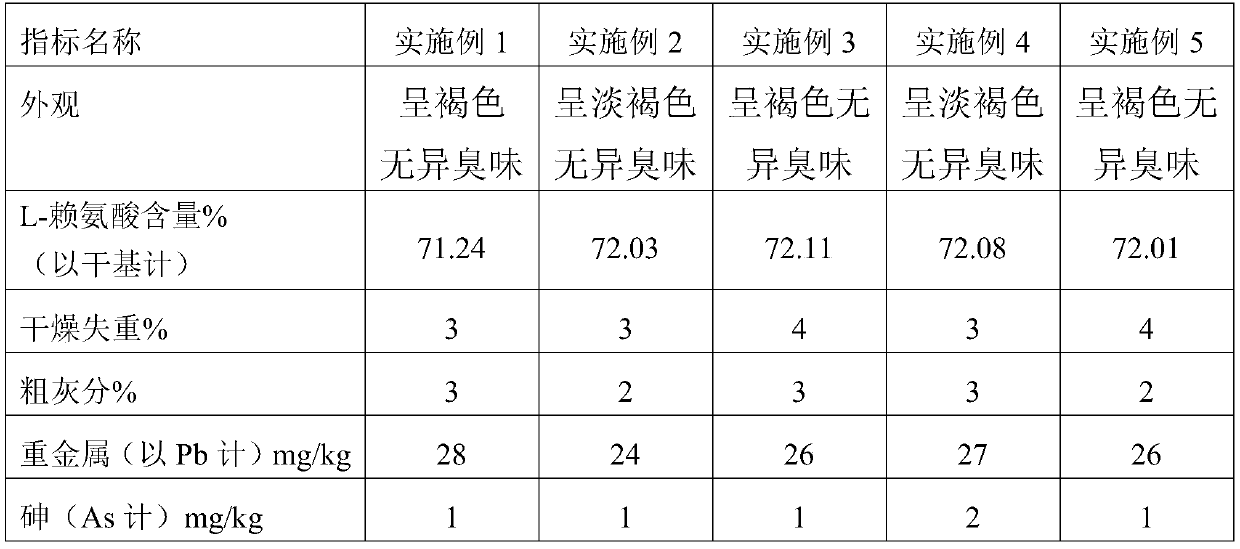

Examples

Embodiment 1

[0020] The present embodiment provides the preparation method of L-lysine sulfate and by-product thereof, comprises the following steps:

[0021] (1) medium sterilization: get fermentation medium, the component of described fermentation medium is: glucose 150g / L, molasses 100g / L, corn steep liquor 15g / L, ammonium sulfate 50g / L, phosphoric acid 1g / L, Potassium chloride 1.5g / L, magnesium sulfate 0.5g / L, ferrous sulfate 0.01g / L, manganese sulfate 0.1g / L, VB1200μg / L, calcium carbonate 40g / L; Before use, ferment medium with 20% NaOH Adjust the pH to 7.0, and then use steam at 125°C to continuously heat the medium to cause the death of microorganisms;

[0022] (2) Fermentation: Insert the Corynebacterium glutamicum into the fermentation medium under aseptic conditions, the insertion amount is 17% of the weight of the medium, the fermentation process control temperature is 35-40 ° C, the pH value is 6.9 and the DO value 25%, the fermentation time is 54 hours, so that Corynebacterium...

Embodiment 2

[0025] The present embodiment provides the preparation method of L-lysine sulfate and by-product thereof, comprises the following steps:

[0026] (1) medium sterilization: get fermentation medium, the component of described fermentation medium is: glucose 150g / L, molasses 100g / L, corn steep liquor 15g / L, ammonium sulfate 50g / L, phosphoric acid 1g / L, Potassium chloride 1.5g / L, magnesium sulfate 0.5g / L, ferrous sulfate 0.01g / L, manganese sulfate 0.1g / L, VB1200μg / L, calcium carbonate 40g / L; Before use, ferment medium with 20% NaOH Adjust the pH to 7.0, and then use 130°C steam to continuously heat the medium to cause the death of microorganisms;

[0027] (2) Fermentation: Insert the Corynebacterium glutamicum into the fermentation medium under aseptic conditions, the insertion amount is 15% of the weight of the medium, the fermentation process control temperature is 35-40 ° C, the pH value is 7.0 and the DO value 20%, the fermentation time is 60 hours, so that Corynebacterium gl...

Embodiment 3

[0030] The present embodiment provides the preparation method of L-lysine sulfate and by-product thereof, comprises the following steps:

[0031] (1) medium sterilization: get fermentation medium, the component of described fermentation medium is: glucose 150g / L, molasses 100g / L, corn steep liquor 15g / L, ammonium sulfate 50g / L, phosphoric acid 1g / L, Potassium chloride 1.5g / L, magnesium sulfate 0.5g / L, ferrous sulfate 0.01g / L, manganese sulfate 0.1g / L, VB1200μg / L, calcium carbonate 40g / L; Before use, ferment medium with 20% NaOH Adjust the pH to 7.1, and then use 120°C steam to continuously heat the medium to cause the death of microorganisms;

[0032] (2) Fermentation: Insert the Corynebacterium glutamicum into the fermentation medium under aseptic conditions, the insertion amount is 18% of the weight of the medium, the fermentation process control temperature is 35-40 ° C, the pH value is 6.8 and the DO value 30%, the fermentation time is 48 hours, so that Corynebacterium gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com