Cu-doped MOF-5 catalyst, preparation method and application thereof

A technology of MOF-5 and catalyst, which is applied in the field of Cu-doped MOF-5 catalyst and its preparation, can solve the problems of poor recycling performance, easy decomposition, poor catalyst stability, etc., and achieve the effect of facilitating industrial production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] A kind of preparation method of Cu-doped MOF-5 type catalyst, comprises the steps:

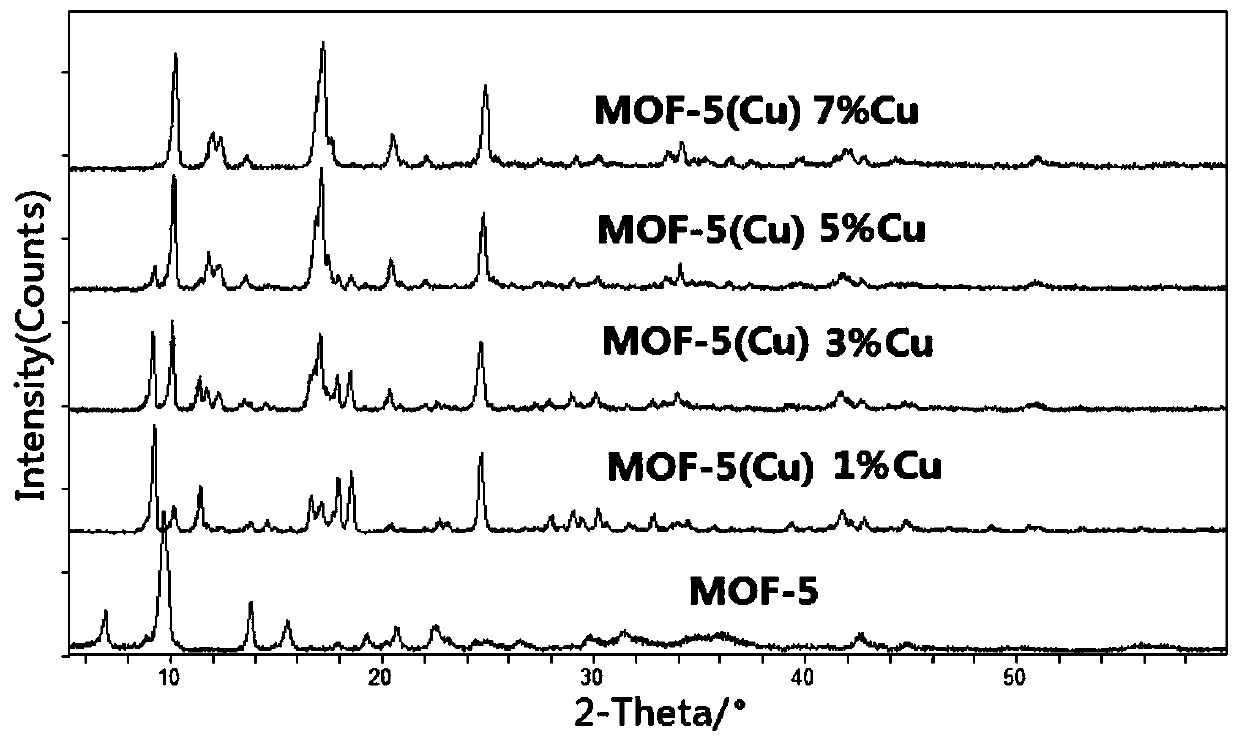

[0016] Mix zinc salt, copper salt, solvent, terephthalic acid and catalyst, and react to obtain MOF-5(Cu);

[0017] The MOF-5(Cu) is calcined.

[0018] In the present invention, zinc salt, copper salt, solvent, terephthalic acid and catalyst are mixed to react to obtain MOF-5 (Cu); then the MOF-5 (Cu) is calcined to obtain Cu-doped MOF-5 catalyst. By doping copper into the structure of MOF-5, the catalytic active sites are firmly combined with MOF-5, and a Cu-doped MOF-5 catalyst with very good stability can be obtained. The preparation method has simple process and is beneficial to industrialized production.

[0019] Preferably, the preparation method of Cu-doped MOF-5 type catalyst of the present invention, comprises the steps:

[0020] (1) At room temperature, mix zinc salt, copper salt, solvent 1 and terephthalic acid, stir constantly, wait for the solid to dissolve completely, ...

Embodiment 1

[0038] This example provides a Cu-doped MOF-5 catalyst, its preparation method and application.

[0039] The first step: weigh 0.0051mol (1.52g) of Zn(NO 3 ) 2 ·6H 2 O and 8.1×10 -5 mol(0.0152g) of Cu(NO 3 ) 2 ·3H 2 O, mix with 50mL of DMF, add 0.0038mol (0.6375g) of terephthalic acid to the system at room temperature, keep stirring, wait for the solid to dissolve completely, then add 2.75mL of triethylamine into the mixed solution, Stir continuously and react for 2 hours to obtain a white solid, which is filtered with suction and washed with DMF 4 times during the suction filtration to remove unreacted inorganic salts and organic acids in the product. The samples were ground and loaded to obtain MOF-5(Cu)1%Cu(mass fraction).

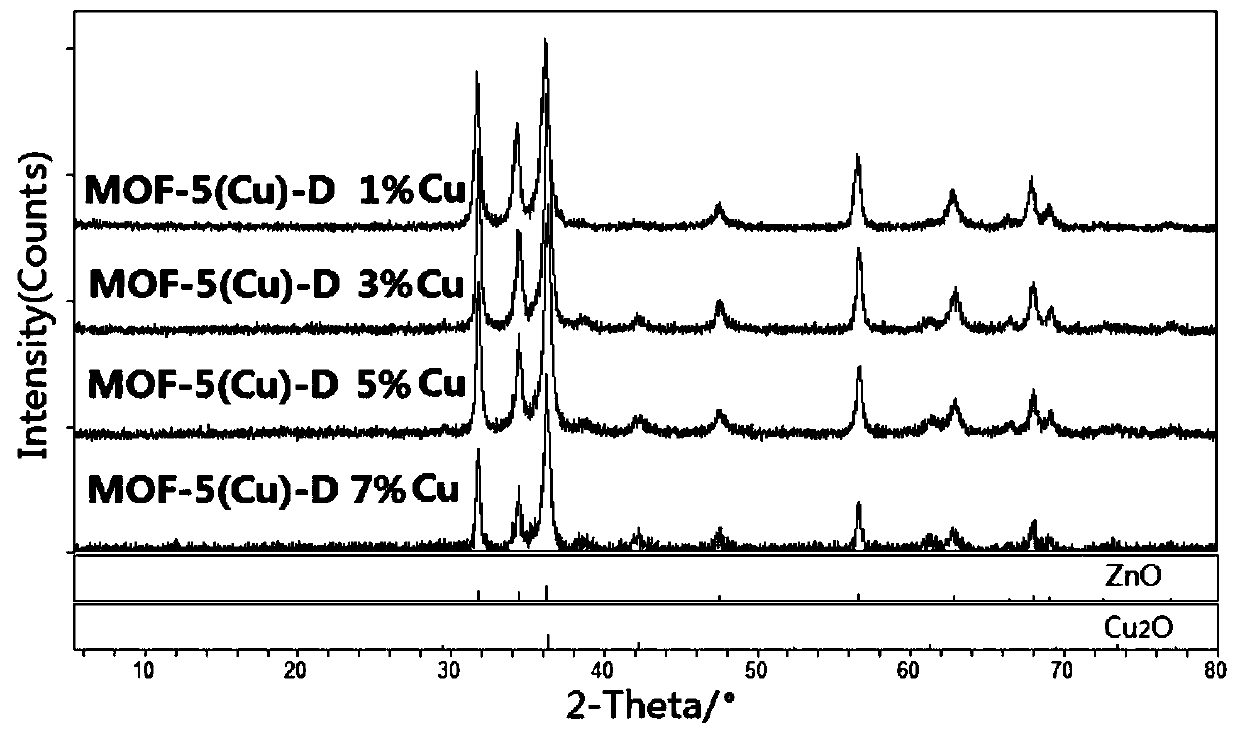

[0040] The second step: put MOF-5(Cu) 1% Cu in a tube furnace, and heat up to 600°C for 2 hours at a heating rate of 10°C / min in an air atmosphere to obtain MOF-5(Cu)-D 1% Cu catalyst.

[0041] Step 3: Weigh 0.05g of MOF-5(Cu)-D 1% Cu catalyst,...

Embodiment 2

[0046] This example provides a Cu-doped MOF-5 catalyst, its preparation method and application.

[0047] The first step: weigh 0.0051mol (1.52g) of Zn(NO 3 ) 2 ·6H 2 O and 1.62×10 -4 mol(0.0304g) of Cu(NO 3 ) 2 ·3H 2 O, mix with 50mL of DMF, add 0.0038mol (0.6375g) of terephthalic acid to the system at room temperature, keep stirring, wait for the solid to dissolve completely, then add 2.75mL of triethylamine into the mixed solution, Stir continuously and react for 2 hours to obtain a white solid, which is filtered with suction and washed with DMF 4 times during the suction filtration to remove unreacted inorganic salts and organic acids in the product. The sample was ground and loaded to obtain MOF-5(Cu) 3%Cu.

[0048] The second step: put MOF-5(Cu) 3% Cu in a tube furnace, and heat up to 600°C for 2 hours at a heating rate of 10°C / min in an air atmosphere to obtain MOF-5(Cu)-D 3% Cu catalyst.

[0049] Step 3: Weigh 0.05g of MOF-5(Cu)-D 3% Cu catalyst, weigh 0.88mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com