Method for preparing multicolor fluorescent carbon dot by solvent-free technology, and multicolor fluorescent carbon dot prepared therethrough

A fluorescent carbon dot, solvent-free technology, applied in chemical instruments and methods, nano-carbon, nano-optics, etc., can solve the problems of harsh experimental conditions, low synthesis efficiency, cumbersome purification process, etc., to reduce synthesis cost and reaction pressure , The effect of simple purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

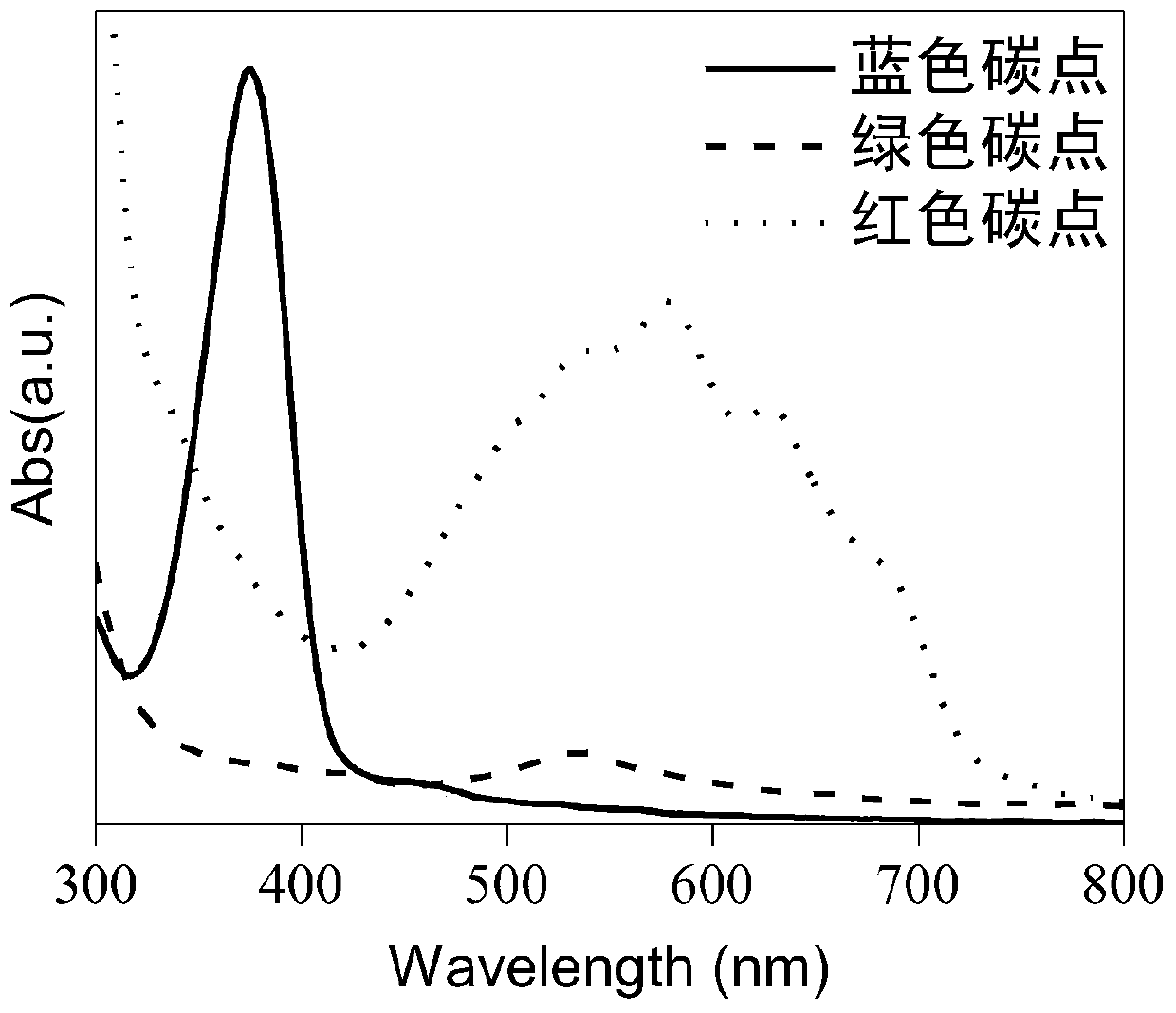

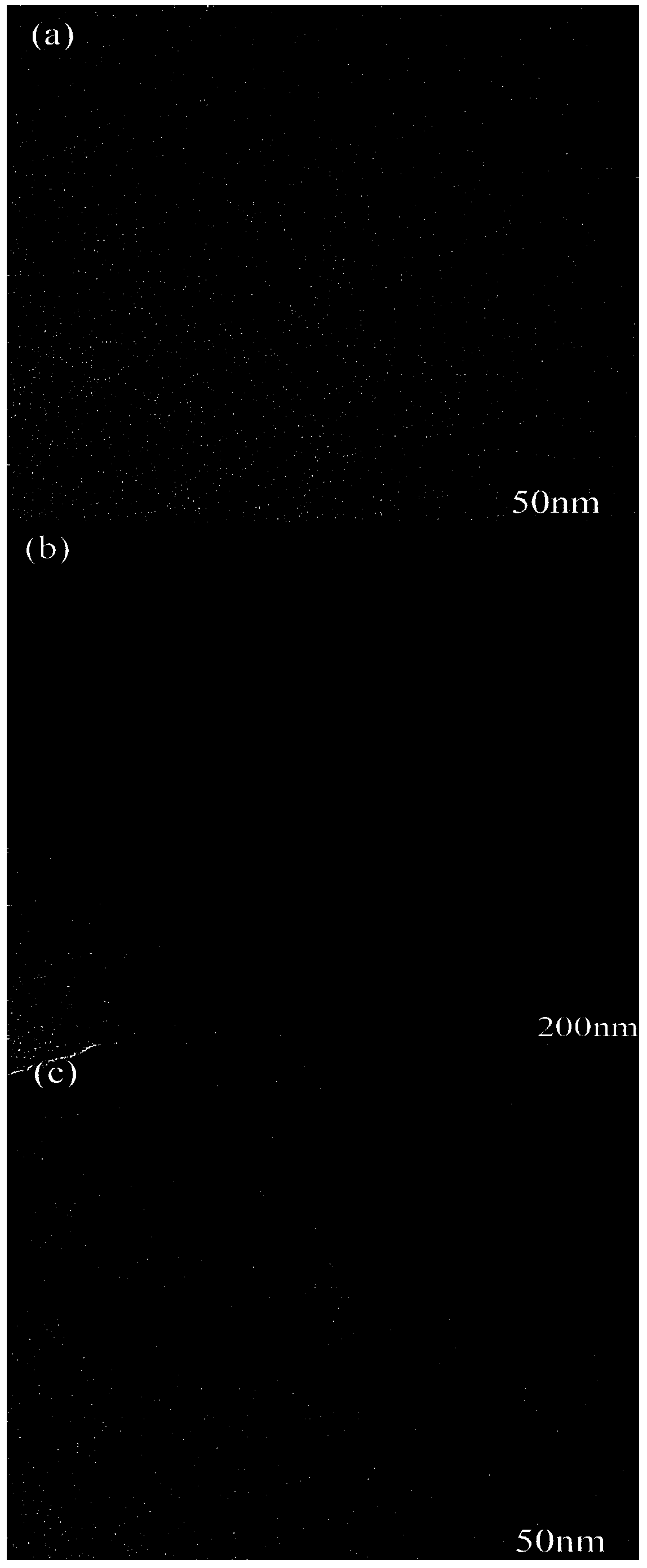

[0027] A method for preparing multicolor fluorescent carbon dots by a solvent-free method, comprising the steps of:

[0028] (1) Preparation of blue fluorescent carbon dots

[0029] Put m-phenylenediamine and aluminum chloride in a mortar with a molar ratio of 5:1, grind it into a powder with uniform particles, then transfer the mixed powder to the lining of the reaction kettle and keep it sealed; preheat the oven to 200°C , put the autoclave into an oven for reaction for 5 hours, after the reaction is completed, turn off the oven, and let it cool down to room temperature naturally; then wash and dry the product with deionized water to obtain a pure blue carbon dot sample. The carbon dots are dispersed in ethanol solution and the fluorescence quantum yield is as high as 79.2%.

[0030] (2) Preparation of green fluorescent carbon dots

[0031] Put p-phenylenediamine, aluminum chloride, and citric acid in a molar ratio of 5:1:1 into a mortar, grind into a powder with uniform p...

Embodiment 2

[0039] A method for preparing multicolor fluorescent carbon dots by a solvent-free method, comprising the steps of:

[0040] (1) Preparation of blue fluorescent carbon dots

[0041] Put m-phenylenediamine and aluminum chloride in a mortar with a molar ratio of 5:1, grind it into a powder with uniform particles, then transfer the mixed powder to the lining of the reaction kettle and keep it sealed; preheat the oven to 180°C , put the high-pressure reactor into an oven to react for 5 hours, after the reaction is completed, turn off the oven, and cool to room temperature naturally; then wash and dry the product with deionized water to obtain a pure blue light carbon dot sample. The carbon dots were dispersed in ethanol solution and the fluorescence quantum yield was measured to be 57.3%.

[0042] (2) Preparation of green fluorescent carbon dots

[0043] Put p-phenylenediamine, aluminum chloride, and citric acid in a molar ratio of 5:1:1 into a mortar, grind into a powder with u...

Embodiment 3

[0047] A method for preparing multicolor fluorescent carbon dots by a solvent-free method, comprising the steps of:

[0048] (1) Preparation of blue fluorescent carbon dots

[0049] Put m-phenylenediamine and aluminum chloride in a mortar with a molar ratio of 5:2, grind it into a powder with uniform particles, then transfer the mixed powder to the lining of the reaction kettle and keep it sealed; preheat the oven to 180°C , put the high-pressure reactor into an oven to react for 10 hours. After the reaction is completed, turn off the oven and let it cool down to room temperature naturally; then wash and dry the product with deionized water to obtain a pure blue light carbon dot sample. The carbon dots were dispersed in ethanol solution and the fluorescence quantum yield was measured to be 69.1%.

[0050] (2) Preparation of green fluorescent carbon dots

[0051] Put p-phenylenediamine, aluminum chloride, and citric acid in a molar ratio of 5:2:1 into a mortar, grind it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com