Polycarboxylate superplasticizer and preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of polycarboxylic acid water reducing agent and its preparation, can solve the problems of fluidity, poor slump retention, and unsatisfactory application, so as to improve slump retention performance and enhance slump retention performance , Improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

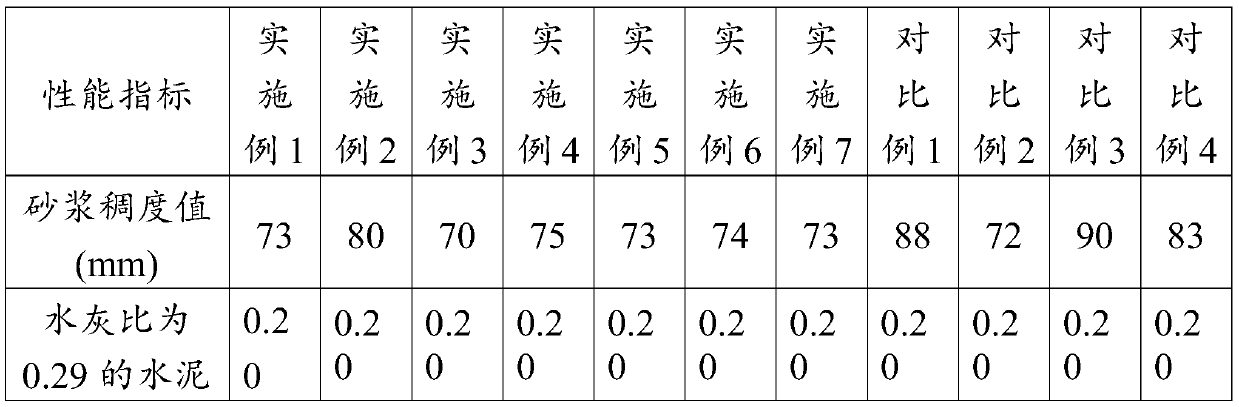

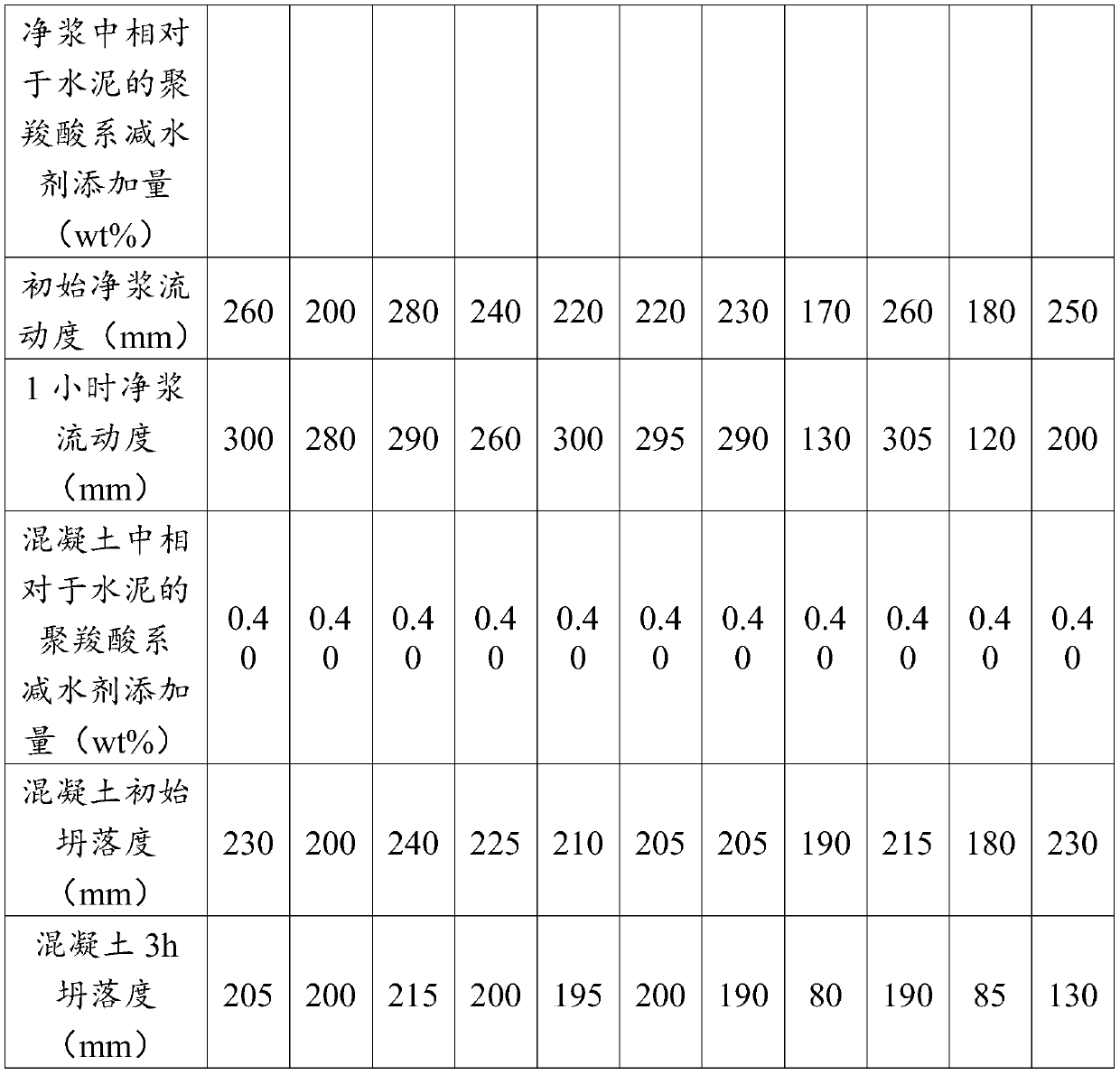

Examples

Embodiment 1

[0044] This embodiment provides a polycarboxylate water reducer and its preparation method, specifically comprising the following steps:

[0045] Preparation of Solution A: Dissolve 100kg of acrylic acid, 100kg of methacrylic acid, 5kg of hydroxypropyl acrylate, and 5kg of hydroxyethyl acrylate in 800L of water, mix well, and set aside;

[0046] Preparation of Solution B: Dissolve 1.5kgL-ascorbic acid, 1.5kg sodium formaldehyde sulfoxylate, 4kg mercaptoethanol, 4kg mercaptopropionic acid in 1000L water, mix well, and set aside;

[0047] Preparation of solution C: 0.01kg ferrous sulfate and 500kg VOPEG (number average molecular weight is 400), dissolved in 400L water, mixed evenly, set aside;

[0048] Preparation of Solution D: Dissolve 1000kg TPEG (number average molecular weight: 2400), 30kg hydrogen peroxide in 1000L water, mix well, and set aside;

[0049] Add solution D to the reaction kettle, and then add solution B dropwise at 20°C under stirring. When solution B is add...

Embodiment 2

[0051] This embodiment provides a polycarboxylate water reducer and its preparation method, specifically comprising the following steps:

[0052] Preparation of solution A: 20kg of acrylic acid, 5kg of methacrylic acid, 15kg of hydroxypropyl acrylate, and 15kg of monoethyl maleate were dissolved in 500L of water, mixed evenly, and set aside;

[0053] Preparation of solution B: dissolve 3kgL-ascorbic acid, 4kg sodium formaldehyde sulfoxylate, 2.5kg mercaptoethanol, and 2.5kg mercaptopropionic acid in 900L of water, mix well, and set aside;

[0054] The preparation of solution C: 0.08kg ferrous chloride, 100kg VOPEG (the number average molecular weight is 1000), dissolve in 500L water, mix well, set aside;

[0055] Preparation of Solution D: Dissolve 1000kg TPEG (number average molecular weight: 2000), 10kg hydrogen peroxide in 900L water, mix well, and set aside;

[0056] Add solution D to the reaction kettle, and then add solution B dropwise at 20°C under stirring. When solut...

Embodiment 3

[0058] This embodiment provides a polycarboxylate water reducer and its preparation method, specifically comprising the following steps:

[0059] Preparation of Solution A: Dissolve 200kg of acrylic acid, 100kg of itaconic acid, 30kg of hydroxypropyl acrylate, and 30kg of hydroxyethyl acrylate in 600L of water, mix well, and set aside;

[0060] Preparation of solution B: dissolve 3kgL-ascorbic acid, 2kg sodium formaldehyde sulfoxylate, 5kg mercaptoethanol, and 5kg mercaptopropionic acid in 800L of water, mix well, and set aside;

[0061] Preparation of solution C: 0.1kg ferrous acetate, 1000kg VOPEG (number average molecular weight is 2000), dissolved in 800L water, mixed evenly, set aside;

[0062] Preparation of Solution D: Dissolve 1000kg TPEG (number average molecular weight: 3000), 20kg hydrogen peroxide in 800L water, mix well, and set aside;

[0063] Add solution D to the reaction kettle, and then add solution B dropwise at 20°C under stirring. When solution B is added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com