Method for preparing tungsten photocatalyst heterojunction through doping induction

A photocatalyst and heterojunction technology, applied in the field of materials, can solve the problems of high carrier interface transport energy barrier, lower carrier energy, unstable combination of "junction" structure, etc., so as to improve the photocatalytic performance and energy. Effects with structural optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

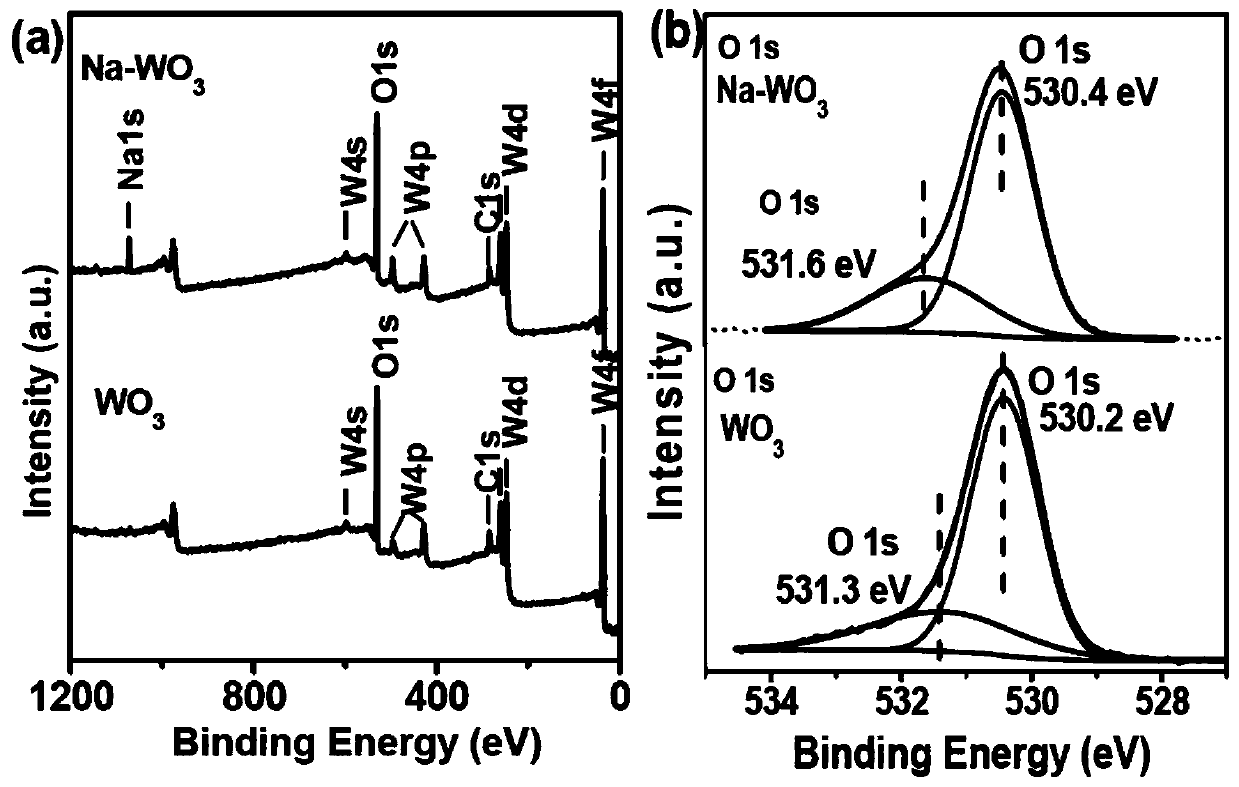

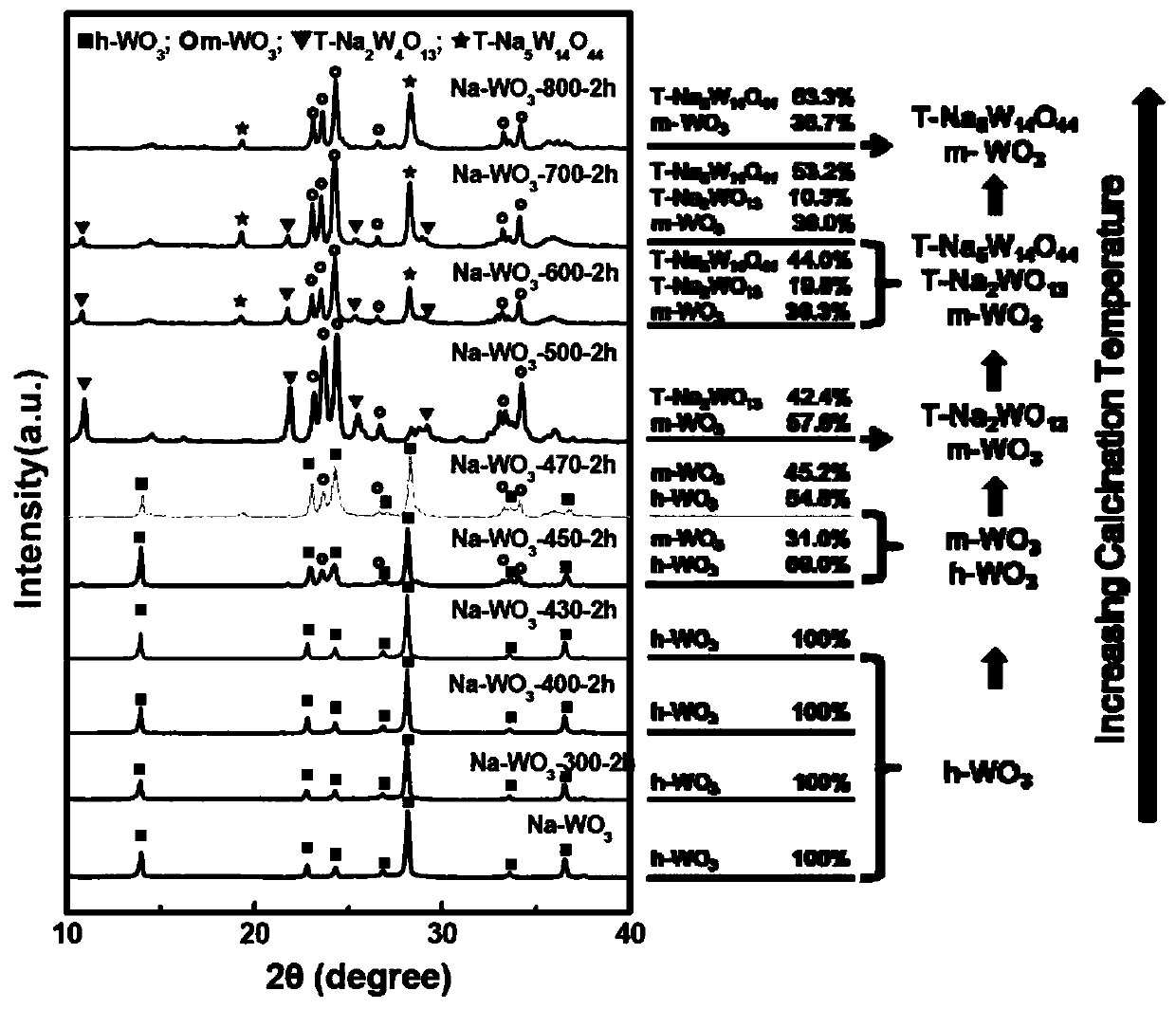

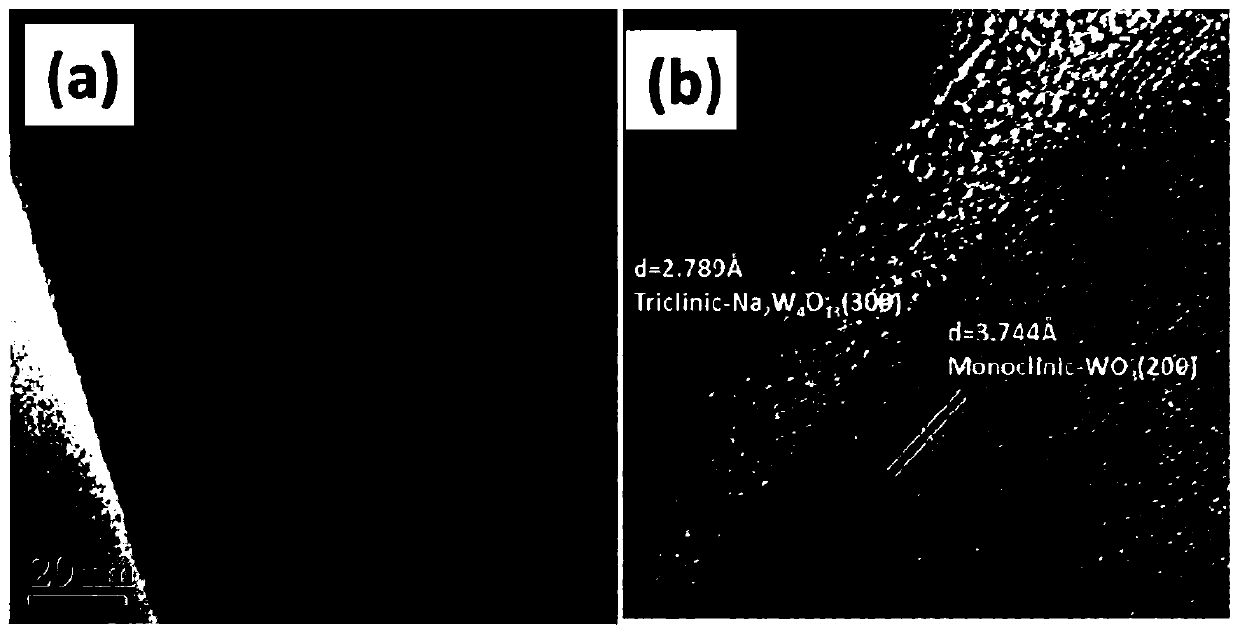

[0026] The method for preparing a tungsten-based photocatalyst heterojunction photocatalyst induced by doping with alkali metal Na ions comprises the following steps:

[0027] (1) 0.005mol of sodium tungstate (Na 2 WO 4 2H 2 O), 0.025 sodium sulfate (Na 2 SO 4 ) and 0.1 citric acid (C 6 h 8 o 7 ) was quickly dissolved in 50mL of deionized water under vigorous magnetic stirring, and continued to stir for 10 minutes after it was completely dissolved;

[0028] (2) Add hydrochloric acid (HCl) drop by drop with a pipette gun to adjust the pH to 1.8, and continue stirring for 10 minutes after the pH reading is stable;

[0029] (3) The above solution was then transferred to a polytetrafluoroethylene reactor, and reacted at a high temperature of 150°C for 24 hours in a hydrothermal oven, and precipitated at the bottom of the reactor after the reaction;

[0030] (4) Centrifuge the precipitated sample obtained above, wash three times with deionized water, and then wash three tim...

Embodiment 2

[0048] A method for preparing a tungsten-based photocatalyst heterojunction photocatalyst induced by doping with alkali metal K ions comprises the following steps:

[0049] (1) 3g potassium tungstate (K 2 WO 4 2H 2 O), 1.84g potassium sulfate (K 2 SO 4 ) and tartaric acid under intense magnetic stirring conditions, quickly dissolved in 50mL of deionized water, after waiting for it to dissolve completely, continue to stir for 10min;

[0050] (2) Add hydrochloric acid (HCl) dropwise with a pipette gun to adjust pH=2.5;

[0051] (3) The above solution was then transferred to a polytetrafluoroethylene reactor, and reacted at a high temperature of 180°C for 30 hours in a hydrothermal oven, and precipitated at the bottom of the reactor after the reaction;

[0052] (4) Centrifuge the precipitated sample obtained above, wash it three times with deionized water, and then wash it three times with absolute ethanol, and then dry the obtained wet sample in a hydrothermal oven at 60°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com