Electro-Fenton cluster magneto-rheological composite grinding and polishing device and method

A polishing device and magnetorheological technology, which are applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problem of low polishing efficiency, low processing efficiency and workpiece processing of magnetorheological polishing technology. Uniformity is difficult to guarantee and other problems, to achieve the effect of improving processing efficiency and processing uniformity, reducing cost, improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

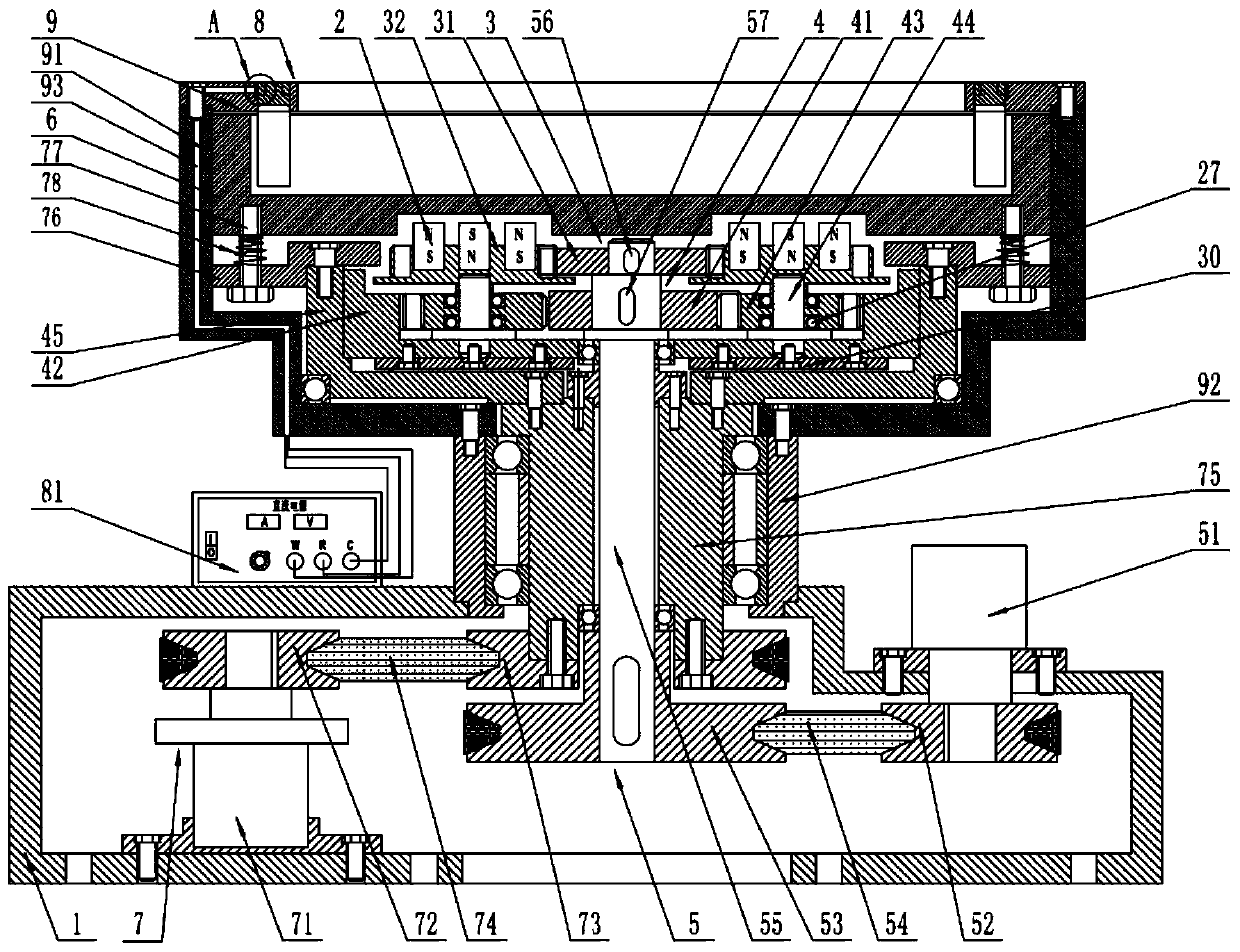

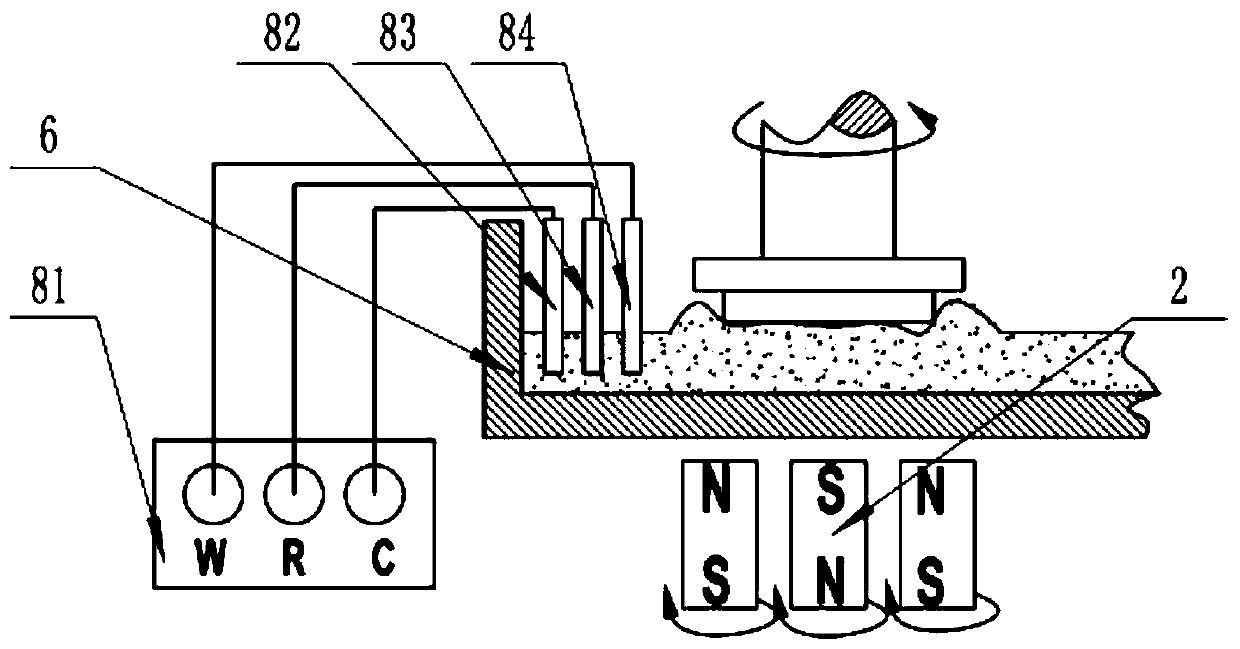

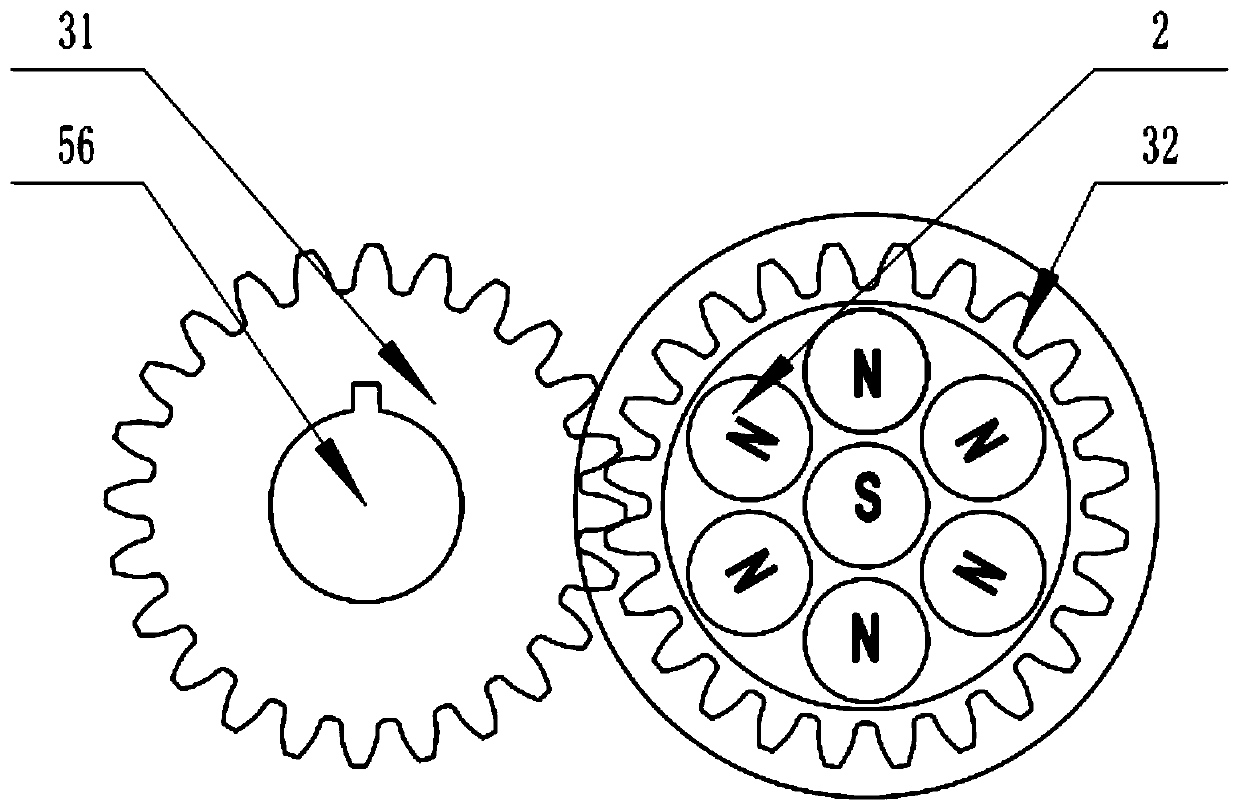

[0046] Such as Figure 1 to Figure 8 Shown is an embodiment of the electric Fenton cluster magnetorheological compound grinding and polishing device of the present invention, including a base 1, a cluster magnet 2, an autorotation transmission assembly 3 that drives the cluster magnet 2 to rotate, and a revolution transmission assembly 4 that drives the cluster magnet 2 to revolve , the first driving assembly 5 that provides power for the rotation and revolution of the cluster magnet 2, the polishing disk 6 filled with magnetorheological fluid, the second driving assembly 7 that drives the polishing disk 6 to rotate, and the electric Fenton reaction that can produce OH The electric Fenton assembly 8 of the reactant, the cluster magnet 2 is installed on the rotation transmission assembly 3, the rotation transmission assembly 3 is connected between the cluster magnet 2 and the first drive assembly 5, and the revolution transmission assembly 4 is connected to the first drive assem...

Embodiment 2

[0067] This embodiment is an embodiment of a grinding and polishing method for processing a 2-inch single-crystal SiC substrate by an electric Fenton cluster magnetorheological composite grinding and polishing device. In this embodiment, diamond abrasives of 100nm to 500nm and 5 μm to 10μm carbonyl iron powder is used as a composite abrasive, and the working method includes the following steps:

[0068] S1. Install the grinding and polishing device on the XY precision mobile platform and move to the origin;

[0069] S2. Install the single crystal SiC workpiece to be processed on the head of the polishing shaft, adjust the gap between the polishing disc 6 and the workpiece to be processed by adjusting the height of the polishing shaft, so as to ensure the grinding and polishing pressure and make the dynamic flexible polishing pad stably formed;

[0070] S3. Configure the magnetorheological fluid and adjust the pH value, and inject it into the polishing disc 6;

[0071] S4. Sta...

Embodiment 3

[0082] This embodiment is an embodiment of a grinding and polishing method for processing a 2-inch single crystal silicon wafer by an electric Fenton cluster magnetorheological compound grinding and polishing device. The carbonyl iron powder of 5 μm is used as composite abrasive material, and this embodiment is similar to the working method of embodiment two, and the difference is:

[0083] In step S3, the magnetorheological fluid is prepared according to the following component ratios and steps: add a composite abrasive with a concentration of 15%, a dispersant with a concentration of 10%, and an antirust agent with a concentration of 5% in deionized water, and stir thoroughly After uniformity, adjust the pH to 3, and then ultrasonically oscillate for 20 minutes to make a composite magnetorheological fluid;

[0084] In step S4, the rotational speed of the first motor 51 is adjusted to 400 rpm, and the rotational speed of the second motor 71 is 100 rpm;

[0085] In step S5, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com