Antibacterial fluorescent protective film for keyboard and preparation method

A protective film and fluorescent technology, applied in the field of computer input devices, can solve the problems of no fluorescent anti-static function, the keyboard film can not inhibit the growth of bacteria, etc., and achieve the effect of good anti-static effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

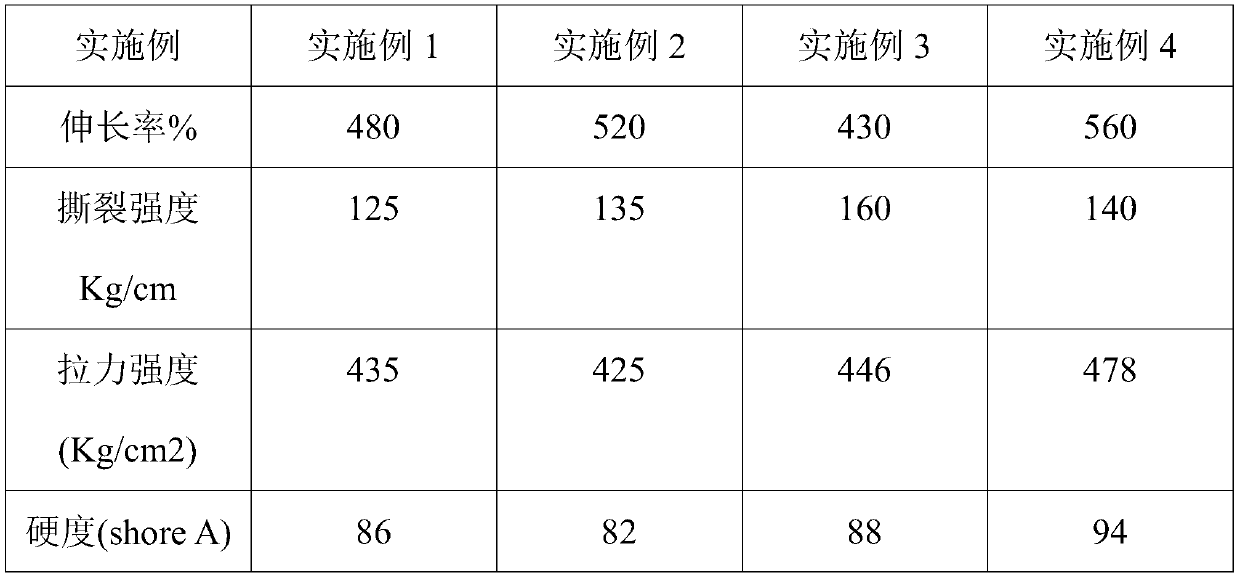

Examples

Embodiment 1

[0026] First, add 0.1 part of phenylenediamine antioxidant; 0.1 part of barium zinc stabilizer; 0.2 part of tea tree oil; 0.3 part of calcium stearate; 4 parts of rare earth aluminate luminous powder to 30 parts of poly Mix in butanediol adipate to obtain a polymer polyol mixed solution; then measure the polymer polyol mixed solution with 25 parts of toluene diisocyanate through a mass flow meter and pour it into a single-screw mixing device for mixing to obtain a preliminary The reaction mixture; then the reaction mixture and 8 parts of chain extender propylene glycol are poured into the co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 120°C, the pressure is 3MPa, the screw speed is 240rpm, and the number of times of kneading is 6 times Between / S, the screw length-to-diameter ratio is 46; the mixture obtained by granulation is poured into a casting extruder for blending and extrusion to obtain an extrudate, and the extrudate is cal...

Embodiment 2

[0028] First, 0.3 parts of phenyl-α-naphthylamine antioxidant; 0.2 parts of barium zinc stabilizer; 0.3 parts of silver-loaded calcium phosphate; 0.4 parts of calcium stearate; 6 parts of rare earth aluminate luminous powder together Added to 40 parts of polybutylene adipate and mixed to obtain a polymer polyol mixed solution; then the polymer polyol mixed solution and 26 parts of toluene diisocyanate were measured by a mass flow meter and poured into a single screw for mixing Mix in the device to obtain a preliminary reaction mixture; then pour the reaction mixture and 12 parts of chain extender 1,4-butanediol into a co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 160 °C, and the pressure is 4MPa, the screw speed is 280rpm, the kneading frequency is between 7 times / S, and the screw length-to-diameter ratio is 46; the mixture obtained by granulation is poured into a cast extruder for blending and extrusion to obtain an extrudate, an...

Embodiment 3

[0030] First, 0.4 parts of phenothiazine antioxidant; 0.3 parts of barium zinc stabilizer; 0.4 parts of silver-loaded glass beads; 0.4 parts of calcium stearate; 8 parts of rare earth aluminate luminous powder were added to 60 Parts of polybutylene adipate are mixed to obtain a polymer polyol mixed solution; then the polymer polyol mixed solution and 26 parts of toluene diisocyanate are measured by a mass flow meter and poured into a single-screw mixing device for Mix to obtain a preliminary reaction mixture; then pour the reaction mixture and 15 parts of chain extender dimethylene phenyl glycol into a co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 200 ° C, and the pressure is 6 MPa. The screw speed is 320rpm, the number of times of kneading is between 8 times / S, and the length-to-diameter ratio of the screw is 46; After calendering, the extrudate is sent to three-stage calendering rollers, where the temperature of the first calen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com